Product Details

| Specification | Details |

|---|---|

| Brand Name | ASTON or OEM |

| Certification | SGS CE ROHS ISO9001 |

| Daily Output | 200KM |

| Minimum Order Quantity | 30km |

| Packaging Details | Normal export packaging |

| Delivery Port | Ningbo |

Common Product Specifications

| Parameter | Value |

|---|---|

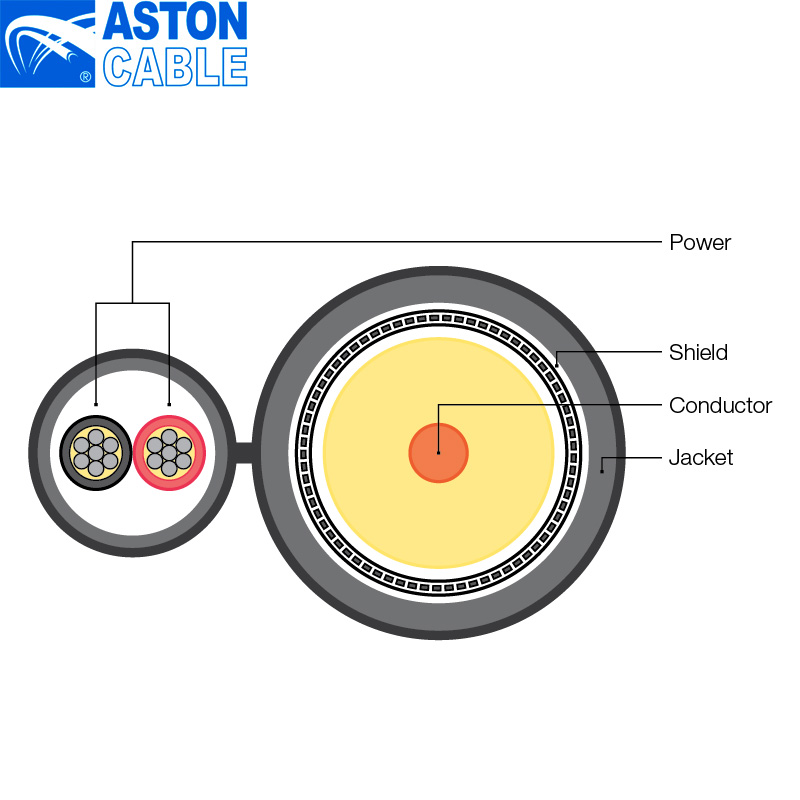

| Conductor | 1.02mm 18AWG CCS |

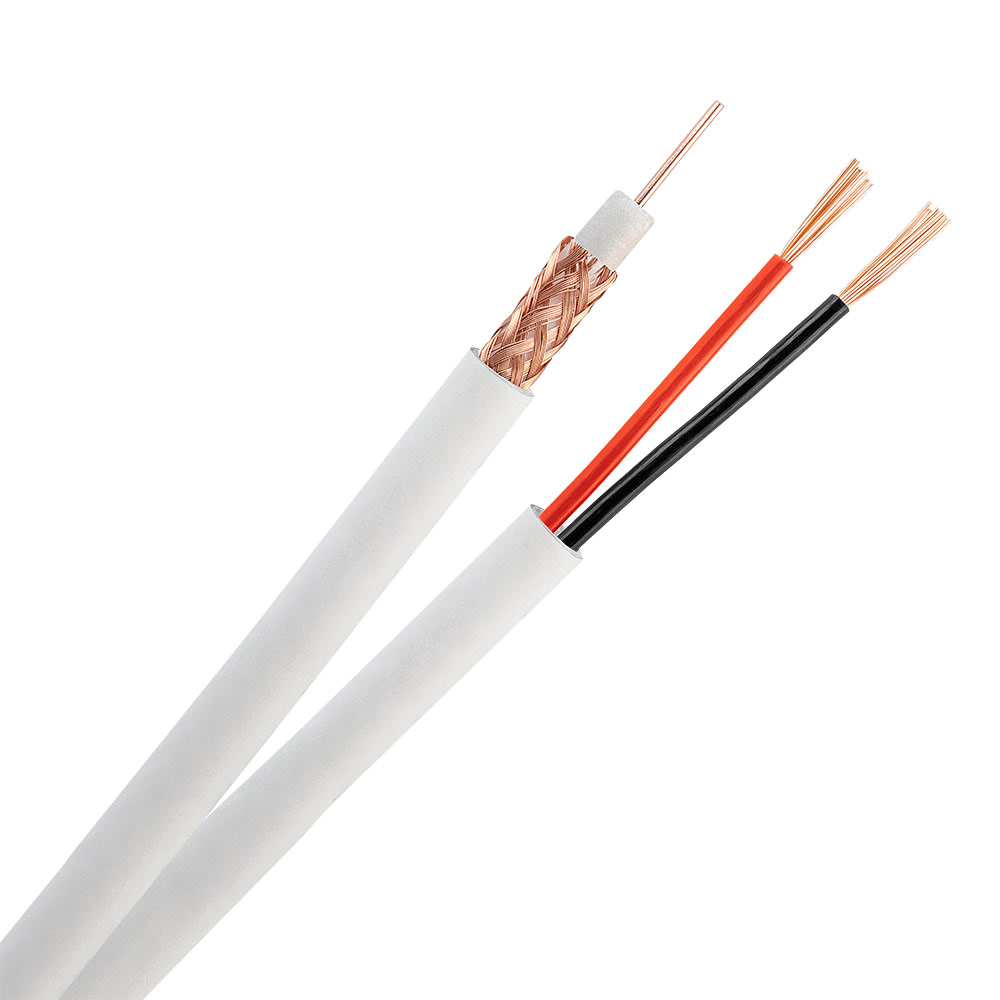

| Jackets | PVC for indoor/ Black PE for outdoor |

| Color | Customized |

| Weight | 6.0KG/100m |

Product Manufacturing Process

The copper clad aluminum wire manufacturing process involves a meticulous bonding procedure where an aluminum core is coated with copper. Through a process like electroplating or hot-dip coating, copper is metallurgically bonded to the aluminum. This ensures optimal conductivity while maintaining the lightweight nature of aluminum. Studies have shown that the copper layer provides corrosion resistance and enhances electrical transmission. In-depth research indicates that this process results in a cost-effective and lightweight alternative to solid copper, suitable for specific applications requiring high-frequency signals.

Product Application Scenarios

Copper clad aluminum wire is predominantly used in telecommunications and high-frequency signal applications due to its favorable conductivity and reduced weight. According to authoritative studies, it seamlessly integrates with CATV, satellite, TV antennas, and broadband internet installations. Its lightweight nature makes it ideal for aerospace and automotive industries where weight is a critical factor. Furthermore, its utilization in CCTV surveillance systems offers a balance between performance and cost-efficiency, as corroborated by industry research.

Product After-Sales Service

Aston Cable offers comprehensive after-sales support, including technical assistance and product replacement in case of defects, ensuring customer satisfaction and maintaining product integrity.

Product Transportation

The product is shipped through reliable logistics partners, ensuring safe and timely delivery. We offer tracking and insurance options for a worry-free transportation experience.

Product Advantages

- Cost-Effectiveness: Lower material cost due to aluminum core.

- Lightweight: Easier handling and installation.

- Good Conductivity: Enhanced by copper cladding.

- Corrosion Resistance: Prolongs product lifespan.

Product FAQ

- What is copper clad aluminum wire? Copper clad aluminum wire consists of an aluminum core with a copper coating, combining the benefits of both metals.

- What are the applications for this cable? It is ideal for telecommunications, CCTV, and other high-frequency signal applications.

- How does the copper layer affect conductivity? The copper layer enhances electrical performance while retaining aluminum's lightweight benefits.

- Is copper clad aluminum wire cost-effective? Yes, it provides significant cost savings compared to solid copper wire.

- How is the product packaged? The product is available in coil reels, plastic drums, wooden drums, and color boxes.

- Can this cable be used outdoors? Yes, it features a black PE jacket suited for outdoor use.

- What certifications does this product have? It is certified by SGS, CE, ROHS, and ISO9001.

- What is the minimum order quantity? The minimum order quantity is 30 kilometers.

- Where is the product manufactured? It is manufactured in Hangzhou, Zhejiang, China.

- What support is available post-purchase? Our after-sales service includes technical support and product replacement if necessary.

Product Hot Topics

- Why choose copper clad aluminum wire over traditional copper? Opting for copper clad aluminum wire offers significant cost reduction and lighter weight compared to traditional copper. Extensive industry discussions indicate that its corrosion resistance and conductivity make it favorable for specific applications like telecommunications and data transmission.

- How does copper clad aluminum wire contribute to sustainability? The manufacturing of copper clad aluminum wire uses fewer resources than pure copper, making it an environmentally friendly option. Industry experts highlight that its reduced weight leads to lower transportation emissions, aligning with sustainable practices favored in modern manufacturing.

Image Description