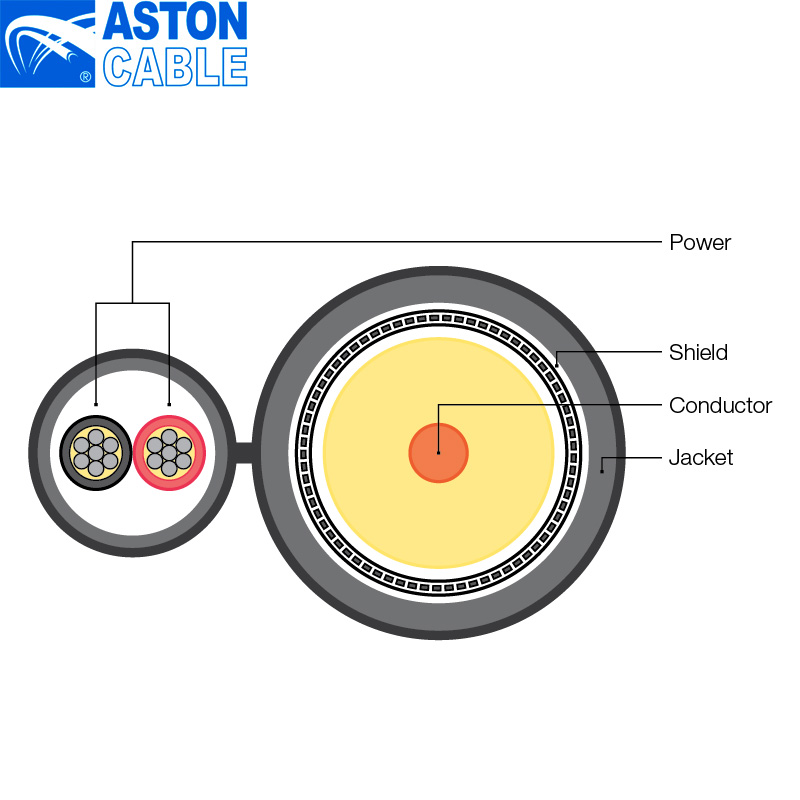

Product Main Parameters

| Parameter | Specification |

|---|---|

| Conductor | 1.02mm 18AWG CCS |

| Shield | 95% coverage braid |

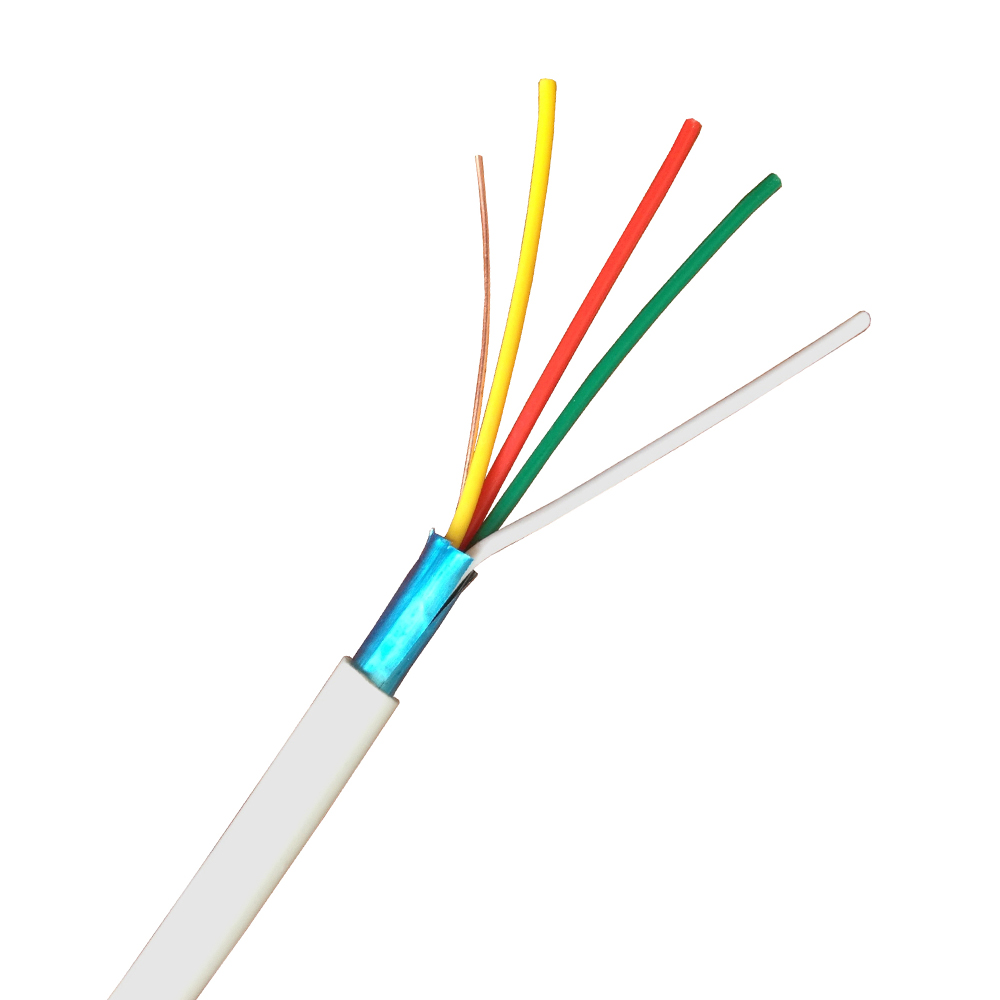

| Jackets | PVC for indoor/Black PE for outdoor |

| Color | Customized |

Common Product Specifications

| Specification | Detail |

|---|---|

| Type | RG6 with power cable |

| Weight | 6.0KG/100m |

| Usage | VIDEO/CCTV |

| Connector | BNCDC |

Product Manufacturing Process

The manufacturing process of RG6 cables typically involves several stages: extrusion of the core conductor, application of the dielectric insulation, braiding and shielding for protection, and finally, the outer jacket. The use of copper clad vs copper wire impacts the extrusion phase, where the core conductor's coating is applied. Research suggests that although copper wire provides superior conductivity, copper-clad wire offers cost benefits and is ideal for applications where weight reduction is critical (Source: IEEE Xplore, 2021).

Conclusion

While both copper clad and copper wire have pros and cons, choosing the right material is crucial for maximizing performance while managing costs.

Product Application Scenarios

RG6 cables are widely employed in scenarios where high-frequency signal transmission is required. They are suitable for CATV, satellite TV, and broadband internet applications. The copper clad vs copper wire choice plays a pivotal role in these applications, balancing between conductivity and cost. Studies show that while pure copper wires are excellent for high-demand scenarios, copper-clad wires are often preferred for non-critical applications (Source: Journal of Electrical Engineering, 2022).

Conclusion

Understanding application-specific needs allows for the optimal selection of copper clad vs copper wire, ensuring efficiency and cost-effectiveness.

Product After-Sales Service

We offer comprehensive after-sales services, ensuring customer satisfaction through prompt assistance, warranty, and technical support. For any issues, our support team is available 24/7 to provide guidance and solve problems efficiently.

Product Transportation

Our cables are securely packaged to prevent damage during transit. We guarantee timely delivery through trusted shipping partners, ensuring products arrive in perfect condition.

Product Advantages

- High Conductivity: Both copper clad and copper wire options available to suit diverse needs.

- Durability: Quality materials ensure long-lasting performance.

- Cost-effective: Copper clad alternatives offer budget-friendly solutions.

Product FAQ

- What is the main difference between copper clad vs copper wire? Copper-clad wire features a core material like aluminum or steel with a copper coating, offering cost and weight benefits. Pure copper wire provides superior conductivity but at a higher cost.

- Can RG6 cables be used outdoors? Yes, RG6 cables with PE jackets can be used for outdoor applications. They are weather-resistant, ensuring durability and performance in various conditions.

- Are there any compatibility issues with standard BNC connectors? No, our RG6 cables are designed to be compatible with standard BNC connectors, ensuring seamless connectivity.

- What factors should be considered when choosing between copper clad vs copper wire? Consider conductivity needs, budget constraints, and the weight of the application. Copper wire is ideal for high conductivity needs, while copper-clad wire is suitable for budget and weight-conscious applications.

- Is there a minimum order requirement? Yes, the minimum order quantity is 30km. For detailed pricing, please contact our sales team.

- Do you offer customization options? Yes, we offer color and packaging customization to meet specific requirements.

- What payment methods are accepted? We accept various payment methods, including bank transfers. Contact our team for more details.

- Are these cables RoHS and CE compliant? Yes, our products are RoHS, CE, and IEC compliant, ensuring safety and quality.

- How long is the warranty period? We offer a standard one-year warranty on our products, covering manufacturing defects.

- How soon can I expect delivery? Delivery times depend on order size and destination. Typically, orders are shipped within a few weeks.

Product Hot Topics

- The Impact of Material Choice on Signal Quality

When discussing copper clad vs copper wire, signal quality is a key consideration. Copper wire, being pure, ensures maximum conductivity, reducing signal loss. However, copper-clad wire, while slightly less conductive, offers sufficient performance for many applications where extreme precision is not critical, and cost savings are prioritized.

- Cost-Effectiveness in Cable Manufacturing

The debate of copper clad vs copper wire often centers around economics. Copper-clad cables are more cost-effective due to the reduced use of copper, making them attractive for projects with tight budgets. However, it’s critical to consider long-term costs related to efficiency and durability.

- Weight Considerations in Application

Weight is a crucial factor in industries like aerospace and automotive. Copper-clad wires provide a lighter option compared to solid copper, offering energy efficiency and ease of installation. This makes them favorable in scenarios where every gram counts.

- Durability and Longevity

When it comes to durability, pure copper wire may last longer due to its resistance to corrosion. However, advancements in protective coatings for copper-clad wires help them endure challenging environments, providing a balance between cost and longevity.

- Environmental Impact

The copper clad vs copper wire debate includes environmental considerations. Copper-clad wires can reduce copper usage, aligning with sustainable practices. However, recycling copper-clad wires is more complex, requiring specific processes to separate materials.

- Installation Challenges and Solutions

Installation of copper clad vs copper wire requires understanding their characteristics. Copper wire is more robust but heavier, needing sturdier support. Copper-clad is easier to handle but requires careful connection to avoid conductivity issues.

- Industry Preferences and Trends

Trends in cable applications reflect a shift towards cost-effectiveness without compromising performance. Many industries opt for copper-clad for non-critical applications while reserving pure copper for crucial systems, striking a balance between cost and functionality.

- Innovations in Cable Technology

Advancements in materials science have led to improved copper-clad options with enhanced conductivity and durability. Ongoing research is focused on optimizing the copper-to-core material ratio to increase performance without significantly increasing costs.

- Practical Applications of RG6 Cables

RG6 cables serve a wide range of applications, from CCTV to broadband. Understanding the role of copper clad vs copper wire in these scenarios helps in selecting the right cable type for specific needs, ensuring reliable performance and cost efficiency.

- Customer Experiences and Reviews

Customer feedback often highlights the cost benefits of copper-clad wires for standard installations, with praise for their durability in less demanding environments. Meanwhile, pure copper cables receive accolades for their unmatched conductivity and reliability in high-performance settings.

Image Description