Product Main Parameters

| Parameter | Details |

|---|---|

| Conductor | Class 5 flexible annealed plain copper |

| Insulation | PVC or XPLE (LSZH) |

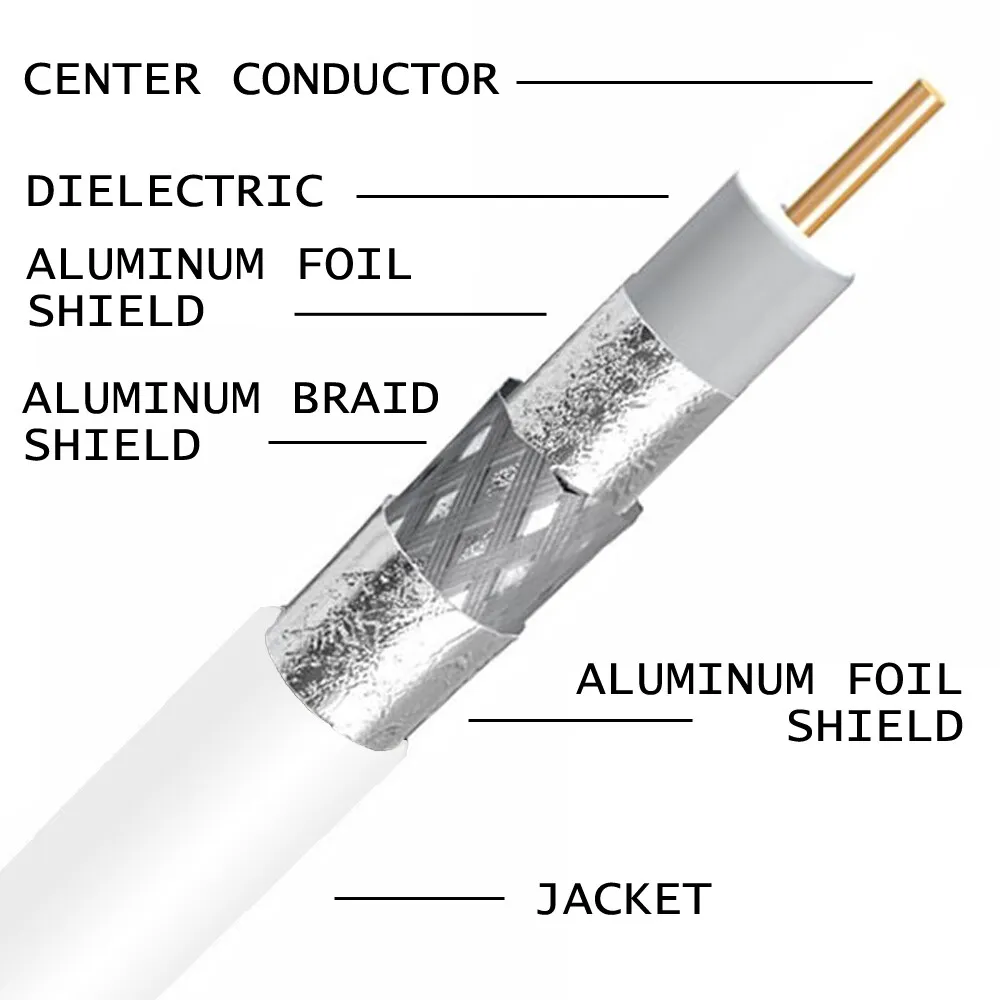

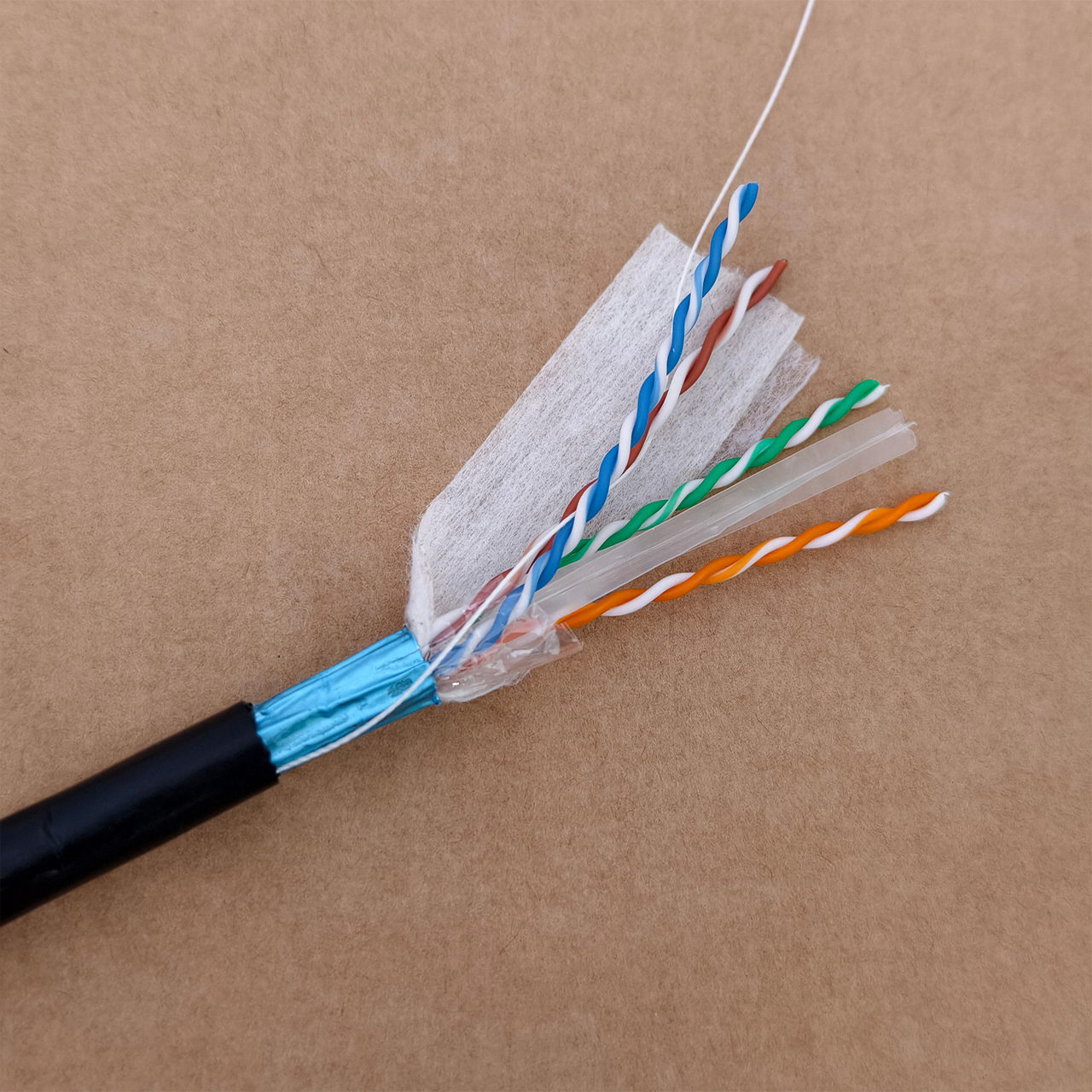

| Shielding | Foil or braided wire |

| Voltage | 5V to 12V |

| Compliance | SGS CE ROHS ISO9001 |

Common Product Specifications

| Part No. | No. Cores | Conductor Area (mm2) | Overall Diameter (mm) | Nominal Weight (kg/km) |

|---|---|---|---|---|

| 2C0.75YY | 2 | 0.75 | 5.9 | 50 |

| 3C1.0YY | 3 | 1.0 | 6.5 | 70 |

Product Manufacturing Process

Access control card reader cables are manufactured through a meticulous process involving drawing, stranding, and insulating operations. The copper conductor is drawn to the desired diameter, ensuring optimal conductivity. Stranding enhances flexibility, supporting applications that require bending. Insulation is applied through extrusion, using PVC or LSZH materials to protect against environmental threats. Shielding is incorporated to prevent electromagnetic interference, followed by jacketing for durability. Quality control measures ensure compliance with industry standards, with final testing to validate electrical and mechanical specifications. This comprehensive manufacturing process guarantees a reliable product, crucial for secure data and power transmission in security systems.

Product Application Scenarios

Access control card reader cables are pivotal in electronic security systems within commercial and industrial facilities. They connect card readers to control panels, ensuring authorized access to restricted areas. In manufacturing plants, these cables integrate into automated systems, facilitating smooth operations by securing access points. In corporate offices, access control cables support employee entry systems, maintaining security integrity. Shielded variants are ideal for environments with high electromagnetic interference, while plenum-rated cables are suited for areas requiring stringent fire safety compliance. As technology evolves, these cables are essential in adapting to enhanced security protocols and access control developments, underscoring their importance in modern security infrastructure.

Product After-Sales Service

We offer comprehensive after-sales support for our access control card reader cables. Our team provides technical assistance, addressing any installation or application inquiries. Should defects occur, we ensure efficient resolution with replacement or repair services, adhering to warranty terms. Customer satisfaction is paramount; thus, we maintain open communication channels for feedback. Our commitment extends to providing updated product information and compatibility guidelines, reflecting changes in security technology. This holistic approach supports customers in optimizing the performance and longevity of access control systems, fostering reliable security solutions.

Product Transportation

We ensure secure transportation of access control card reader cables using durable and eco-friendly packaging materials. Our logistics partners guarantee timely deliveries, adapting to global shipping regulations. Customers receive tracking details, allowing real-time updates on product status. In case of transportation issues, our service team promptly addresses concerns, minimizing disruptions.

Product Advantages

- Reliable data and power transmission

- Support for multiple protocols

- Flexible installation options

- High-quality materials ensure durability

- Shielding against electromagnetic interference

- Compliance with international standards

Product FAQ

What is the primary use of access control card reader cables?

Access control card reader cables are primarily used to connect card readers to control panels in electronic security systems. They facilitate secure data and power transmission, enabling the control system to verify and authenticate access credentials effectively.

Are these cables suitable for outdoor use?

Yes, access control card reader cables can be used outdoors if they are mechanically protected and specified for environmental conditions. It's crucial to choose cables with appropriate insulation and shielding to withstand moisture, temperature extremes, and potential mechanical stress.

Product Hot Topics

Secure Data Transmission in Access Control Systems

The importance of reliable access control card reader cables in ensuring secure data transmission cannot be overstated. These cables are vital for maintaining the integrity of security systems by facilitating accurate communication between card readers and control panels.

Impact of Electromagnetic Interference on Security Cables

Electromagnetic interference (EMI) can disrupt data signals in access control systems, leading to security breaches or failures. Shielded access control card reader cables are designed to mitigate EMI, ensuring continuous, secure data flow in challenging environments.

Image Description