Product Main Parameters

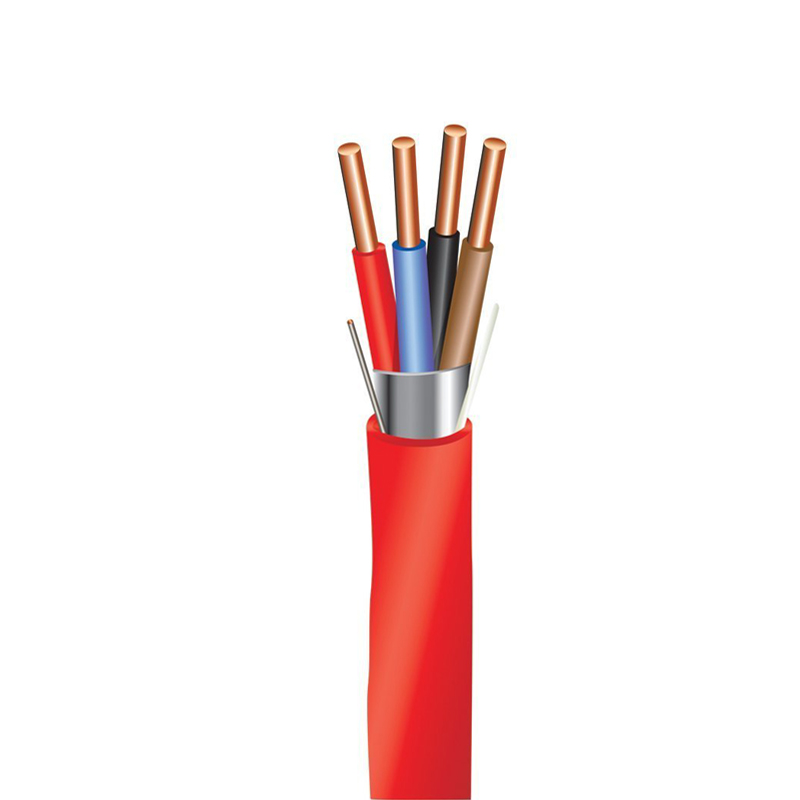

| Conductor Material | OFC Copper |

|---|---|

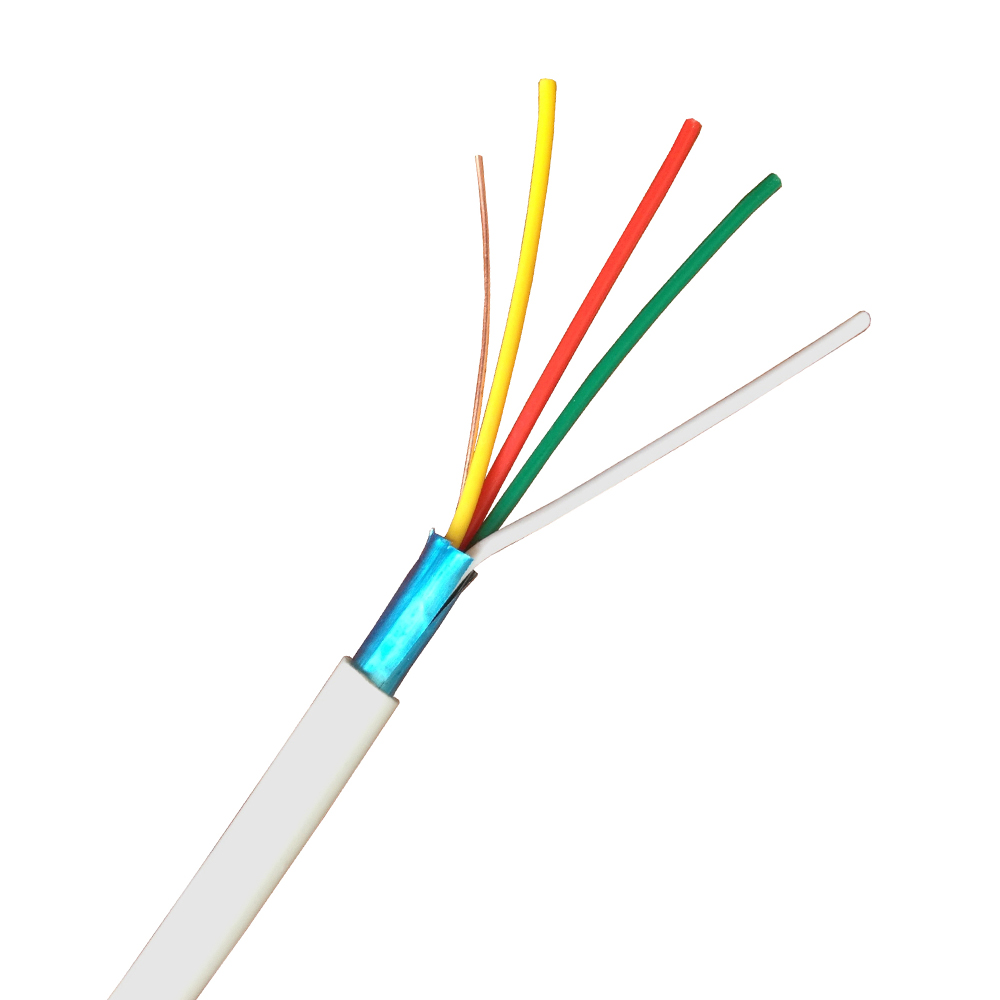

| Cores | 2core, 4core |

| Insulation | PVC, LSZH |

| Jacket | Low smoke PVC |

| Shield | Aluminum Mylar |

| Voltage Rating | 300V |

| Temp. Rating | -5℃ to 75℃ |

Common Product Specifications

| Daily Output | 200KM |

|---|---|

| MOQ | 30km |

| Origin | Hangzhou, Zhejiang |

Product Manufacturing Process

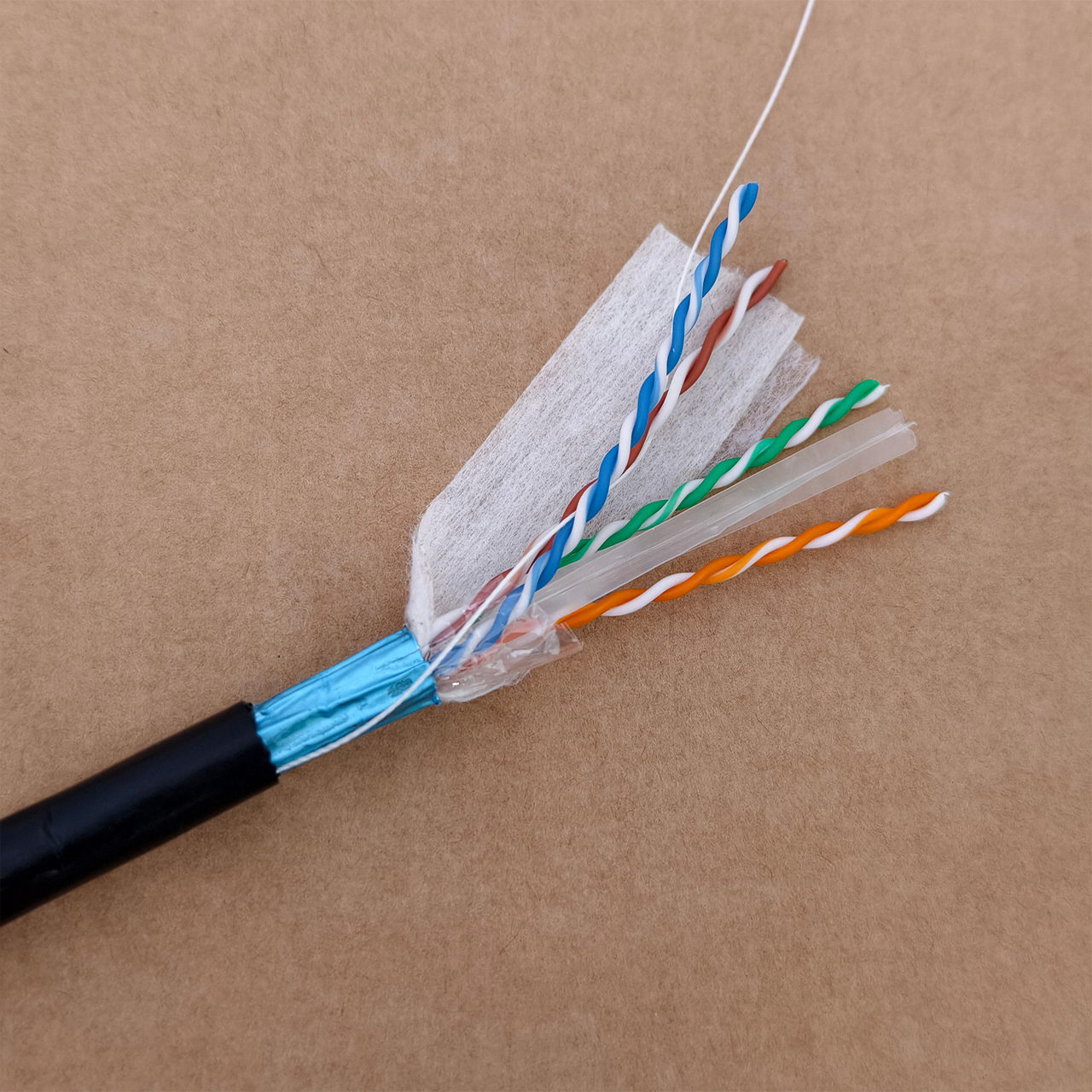

The production of alarm cables involves several stages, beginning with the selection of high-quality copper conductors to ensure optimal conductivity. The copper undergoes stranding processes to achieve the necessary flexibility and durability. Each conductor is then insulated with either PVC or LSZH material, which provides necessary electrical isolation and enhances fire resistance. The insulated cores are assembled and enclosed within a protective outer sheath, often PVC, which shields against physical and environmental damage. This process adheres strictly to international standards ensuring product reliability. Manufacturing efficiency is improved by employing automated systems for braiding and sheathing processes, ensuring uniformity throughout production. Regular testing and quality control measures ensure compliance with industry standards such as IEC, CE, and RoHS.

Product Application Scenarios

Alarm cables are integral to the security systems of both residential and commercial setups. In intruder alarm systems, these cables connect motion detectors, door contacts, and sirens to central control units. For fire alarm systems, they link smoke and heat detectors to alarm panels, ensuring timely alerts during emergencies. Additionally, alarm cables find use in access control systems for connecting card readers and electric locks, facilitating secure access management. Their robust design suits demanding environments like airports and hospitals, where uninterrupted function is crucial during emergencies. Their ability to perform reliably under high temperatures and strenuous conditions positions them as indispensable components in safety infrastructure.

Product After-sales Service

- 24/7 customer support for technical queries and installation guidance.

- Comprehensive warranty covering manufacturing defects.

- Easy return and exchange policies for faulty products.

Product Transportation

Leveraging strategic partnerships with major logistics companies, we ensure timely delivery and safe handling of alarm cables. Packaging is designed to prevent physical damage during transit, with additional safeguards for international shipments. Shipping documentation is accurately prepared to facilitate smooth customs clearance.

Product Advantages

- High-quality OFC copper ensures excellent conductivity and signal integrity.

- Fire-resistant properties protect both people and equipment.

- Compliant with international safety standards for peace of mind.

Product FAQ

- What are the main applications for alarm cables?

Alarm cables are typically used in security systems for intruder alerts, fire alarms, access controls, and connecting various sensors and detectors to central panels. Their reliable performance ensures safety across these applications. - What makes fire-resistant alarm cables different?

Fire-resistant alarm cables are designed with LSZH insulation, minimizing smoke emission and toxic fumes during a fire, enhancing safety for occupants and firefighters. - Can the cables be customized?

Yes, as leading manufacturers, we offer customization options for length, core number, and sheath material to suit specific security system requirements. - Are your cables suitable for outdoor use?

Yes, our alarm cables are available with robust sheathing that offers protection against environmental elements, suitable for both indoor and outdoor installations. - How do I ensure proper installation?

We provide detailed installation guides and 24/7 support to assist you with any technical queries during the installation process. - Do you offer bulk purchase discounts?

Yes, we offer competitive pricing and discounts on bulk orders, allowing you to optimize project budgets effectively. - What certifications do your alarm cables hold?

Our alarm cables are certified by SGS, CE, and RoHS, ensuring compliance with international quality and safety standards. - What payment terms do you offer?

We offer flexible payment terms, including options for negotiation, to cater to varied customer needs. - How do I determine the number of cores needed?

Your system's complexity dictates cores needed. A basic system might need 2-core cables, while a more intricate setup may require 8-core cables. - What is the warranty period for your cables?

Our cables come with a standard warranty period covering any manufacturing defects, ensuring reliable long-term use.

Product Hot Topics

- How does cable quality impact security systems?

The quality of alarm cables significantly influences the reliability and responsiveness of security systems. High-grade materials ensure efficient signal transmission, minimizing delays in alerting unauthorized access or fire incidents. As manufacturers, we strive for optimal quality assurance, offering products that stand up to rigorous industry standards. This commitment elevates system performance, making it crucial in choosing the right cable to secure your premises. - Why are fire-resistant cables crucial for safety?

Fire-resistant cables are vital in maintaining operational integrity during fires, crucial for systems in public buildings like hospitals and airports. These cables, with LSZH insulation, prevent hazardous smoke and fumes, ensuring occupant safety and easing emergency evacuations. For manufacturers, producing such cables requires precision engineering and strict quality controls. Integrating fire-resistant cables in security systems represents a proactive safety measure, prioritizing human life and minimizing property damage.

Image Description