Product Main Parameters

| Parameter | Details |

|---|---|

| Brand Name | ASTON or OEM |

| Place of Origin | China |

| Certification | SGS, CE, ROHS, ISO9001 |

| Daily Output | 200KM |

| Minimum Order Quantity | 30 KM |

Common Product Specifications

| Specification | Details |

|---|---|

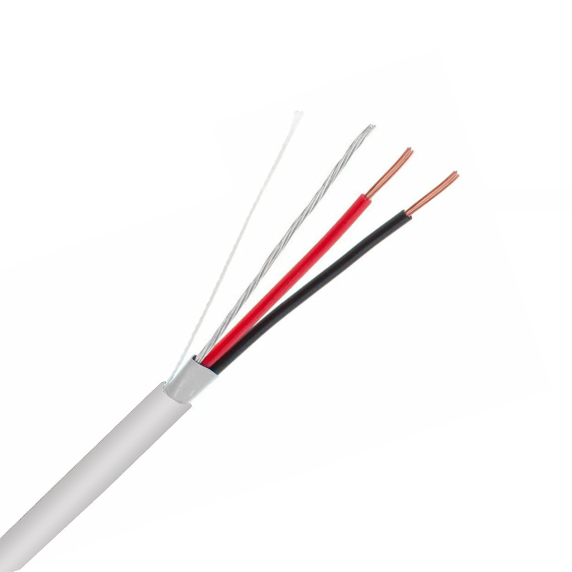

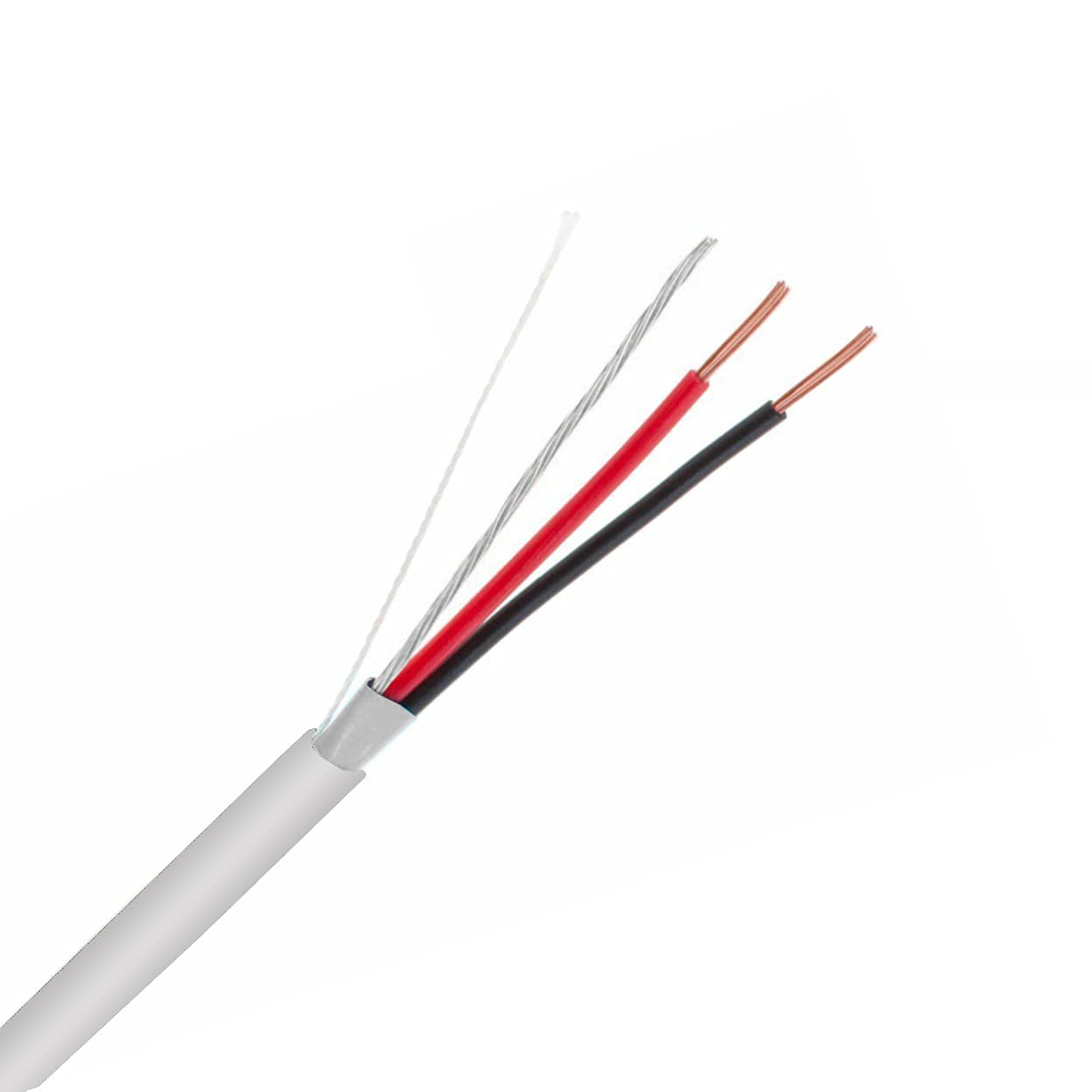

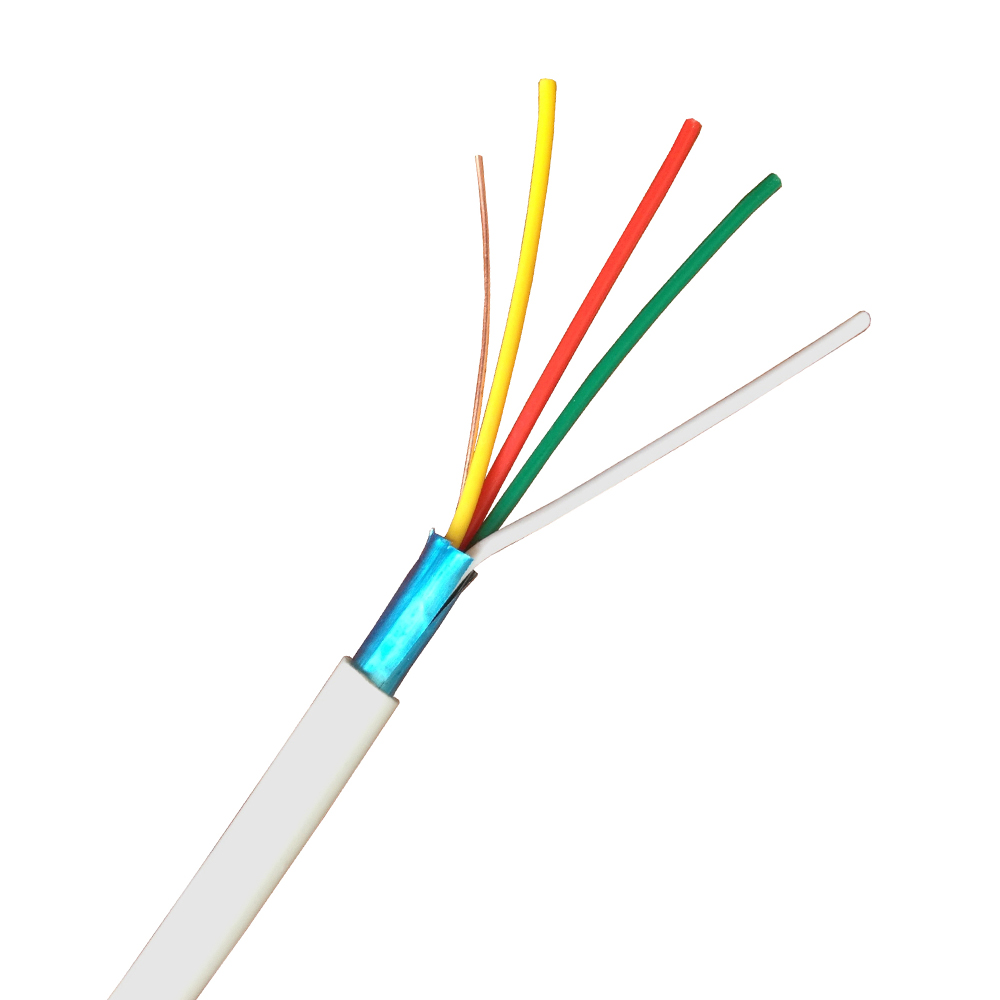

| Conductor | Bare Copper, Solid or Stranded |

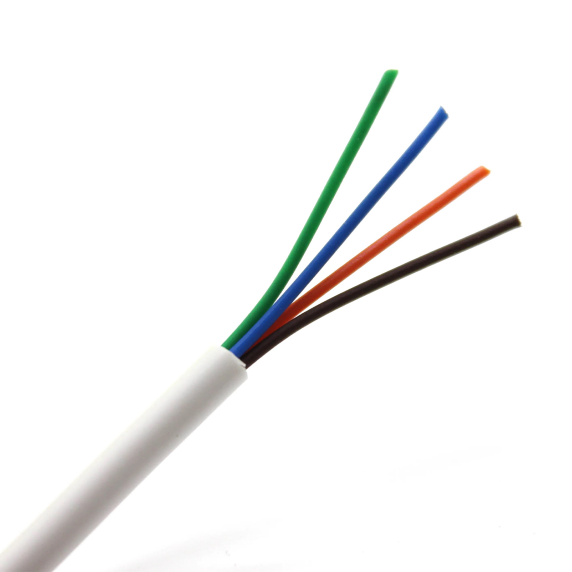

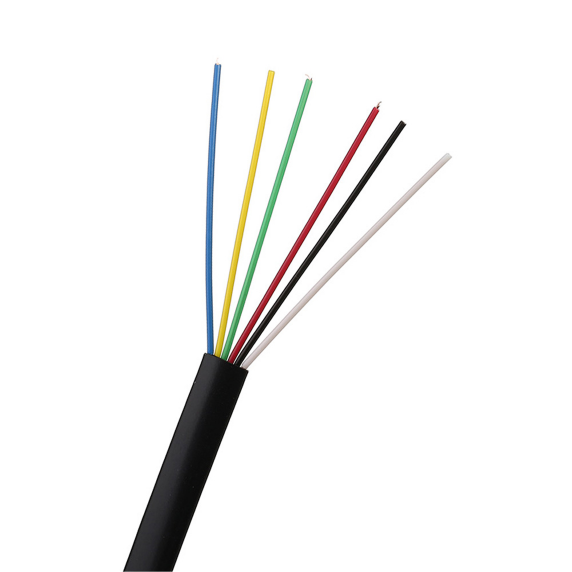

| Core | 2/4/6/8/10/12 |

| Insulation | PVC, Flame Retardant |

| Outer Jacket | PVC, PE, or LSZH |

| Shielding | Aluminum/Polyester, 110% Coverage |

| Drain Wire | Bare Copper, Solid or Stranded |

Product Manufacturing Process

The manufacturing process of fire cables involves several critical stages, ensuring the highest standards of safety and quality. It begins with the selection of high-grade copper conductors due to their superior electrical and thermal properties. These conductors are typically stranded to enhance flexibility and are insulated with thermosetting polymers like XLPE or EPR, which are resilient to high temperatures. The insulation is followed by shielding layers, often made from aluminum/polyester foil, ensuring 110% coverage. Armoring may be included for mechanical protection, using materials like steel wire, offering additional fire resistance. Finally, the cable is jacketed with LSZH materials, minimizing toxic smoke production during fires. This meticulous process ensures the fire cable meets or surpasses industry standards like BS EN 50200, IEC 60331, and UL 2196, ensuring compliance with safety regulations and enhancing reliability during emergencies.

Product Application Scenarios

Fire cables are critical in myriad applications focused on maintaining system integrity during fires. Their primary use is in alarm and detection systems, where uninterrupted operation is crucial for early fire detection and response. They're also vital in powering emergency lighting and signage, providing visibility and guiding evacuation during power failures in fire situations. Life safety systems including ventilation and smoke extraction also rely on fire cables to sustain operation, safeguarding occupants and enabling efficient smoke control. Moreover, these cables are essential for powering critical equipment such as fire pumps and communication systems. Ensuring these applications operate without disruption during an emergency is integral to a comprehensive fire safety strategy, aiding both evacuation and firefighting efforts. Proper installation of fire cables, adhering to specified standards, is indispensable in upholding building codes and ensuring occupant safety.

Product After-Sales Service

- Comprehensive technical support for installation and maintenance.

- Warranty coverage as per the company's policy.

- Assistance with certification and compliance queries.

Product Transportation

The product is packaged using standard export packing methods to ensure safe transportation. Our logistics partners offer reliable delivery services, utilizing optimized routes to minimize transit time. We coordinate closely with shipping firms to track shipments, ensuring timely delivery at the designated ports, primarily Ningbo.

Product Advantages

- High fire resistance ensuring safety and reliability.

- Compliance with key international safety standards.

- Durability and high performance in extreme conditions.

Product FAQ

- What is the primary use of fire cables? Fire cables are designed to maintain circuit integrity during fires, ensuring that essential systems like alarms, emergency lights, and life safety systems continue functioning.

- Why is LSZH material used in fire cables? LSZH materials minimize the production of toxic gases and smoke, crucial for safe evacuation during a fire and reducing inhalation risks.

- What certifications do Aston fire cables comply with? Aston fire cables are certified with BS EN 50200, IEC 60331, and UL 2196, ensuring they meet rigorous safety and performance criteria.

- How does the armoring contribute to fire cable performance? The armoring provides mechanical protection and enhances fire resistance, acting as an additional safeguard against physical and thermal damage.

- What are the main components used in Aston fire cables? Key components include high-grade copper conductors, thermosetting polymer insulation, aluminum/polyester shielding, and LSZH jacketing.

- Can Aston fire cables be used in outdoor installations? Yes, Aston fire cables feature UV-resistant outer sheaths, making them suitable for outdoor applications.

- What is the daily output capacity for Aston fire cables? Aston factory can produce up to 200KM of coaxial cables per day, supporting large-scale project needs.

- How are fire cables tested for fire resistance? Fire cables undergo rigorous testing, including exposure to high temperatures and mechanical shocks, following standards like BS EN 50200 and IEC 60331.

- Are custom lengths available for Aston fire cables? Yes, Aston Cable offers customization to meet specific project requirements, enabling tailored solutions for diverse applications.

- What is the lead time for an order? The lead time depends on order size and specifications, but we strive to deliver products promptly, leveraging efficient production and logistics processes.

Product Hot Topics

- Ensuring Building Safety with Fire Cable Specifications: Fire cables are integral to achieving compliance with building safety codes. Their ability to maintain functionality during a fire ensures that critical systems operate under emergency conditions, facilitating evacuation and minimizing risk to occupants and first responders.

- The Science Behind Fire Resistant Cable Design: The design of fire cables incorporates materials that withstand extreme temperatures. This includes the use of thermosetting polymers for insulation and LSZH compounds for outer sheaths, vital for preventing system failures in high-heat scenarios.

- Fire Cable Specification and Environmental Considerations: Modern fire cable designs emphasize not only safety but also environmental responsibility. Employing LSZH materials reduces harmful emissions, reflecting an industry's shift towards more eco-friendly solutions without compromising on performance.

- Cost-Effectiveness of Fire Cables in Long-Term Safety Planning: Investing in high-quality fire cables, such as those adhering to Aston's specifications, represents a cost-effective strategy. The reliability and durability of these cables reduce maintenance costs and mitigate the risks associated with system failures during fires.

- Technological Advances in Fire Cable Manufacturing: Continuous advancements in material science and manufacturing techniques have significantly improved the performance of fire cables. Aston Cable remains at the forefront, integrating these innovations to enhance product safety and reliability.

- Global Standards and Fire Cable Specification Compliance: Compliance with international standards like IEC and BS is non-negotiable for fire cables. Aston's adherence to such regulations ensures that their products are fit for a global market, maintaining reliability across various jurisdictions.

- Fire Cable Specifications and Installation Best Practices: Proper installation is crucial to fire cable performance. Aston provides comprehensive guidelines and support, emphasizing correct techniques to optimize safety and functionality of the installed systems.

- Adapting Fire Cable Specifications for Emerging Technologies: As technology evolves, so does the application for fire cables. Aston Cable is committed to adapting its specifications to accommodate new tech-driven infrastructures, ensuring continuous protection and system integration.

- The Role of Fire Cables in Smart Building Infrastructures: In smart building technologies, fire cables play a vital role in safeguarding sophisticated systems. They ensure that critical functionalities, such as automated fire alarms and emergency protocols, are upheld without interruption.

- Future Trends in Fire Cable Development: The future of fire cable technology lies in increased efficiency and reduced environmental impact. Aston Cable aims to lead this transition, focusing on innovation that enhances performance while addressing sustainability concerns.

Image Description