Product Main Parameters

| Parameter | Value |

|---|---|

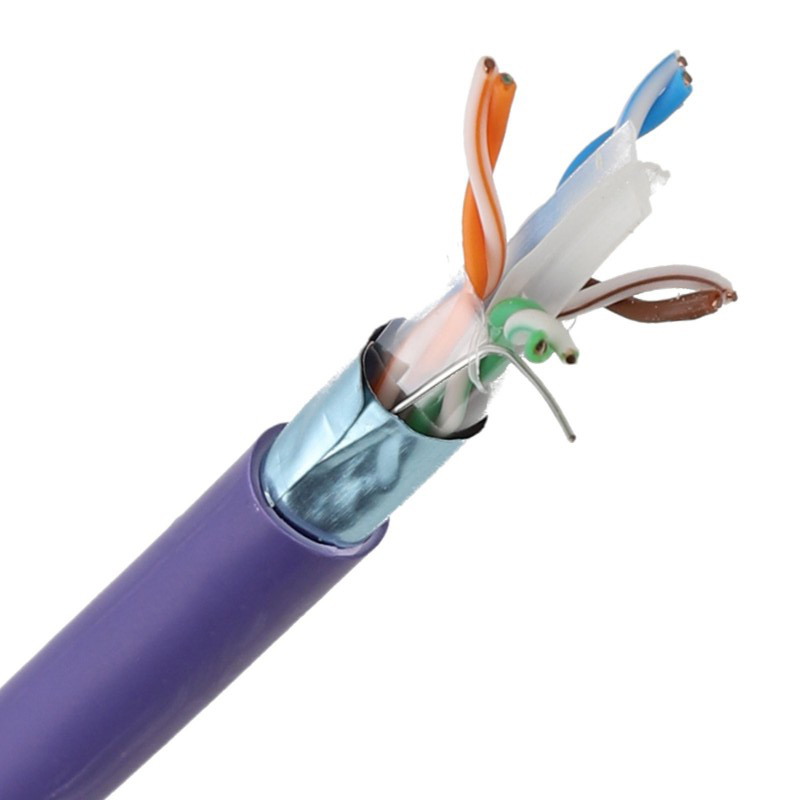

| Standards | Cat6 |

| Gel Type | Petroleum-based |

| Conductor Material | Copper |

| Jacket Material | UV-resistant PVC/PE |

| Length | 1000 ft |

Common Product Specifications

| Specification | Details |

|---|---|

| Data Rate | Up to 1 Gbps |

| Conductor Gauge | 23 AWG |

| Temperature Range | -20°C to 60°C |

| Jacket Thickness | 0.5 mm |

| MOQ | 30 km |

Product Manufacturing Process

Research indicates that the manufacturing process of Cat6 jelly filled cables involves several critical stages to ensure durability and reliability. Starting with the selection of high-quality copper conductors, the cables are then coated with a petroleum-based gel to offer superior moisture protection. The application of an outer jacket using materials such as PVC or PE is crucial for UV resistance and durability. Following the production, rigorous testing is conducted to ensure compliance with Cat6 standards. The process combines advanced machinery and quality control systems, ensuring the final product meets the industry's high standards. Industry papers highlight the importance of quality control during gel application and outer jacket extrusion, as these factors significantly impact the cable's performance in harsh environments.

Product Application Scenarios

According to authoritative sources, Cat6 jelly filled cables are essential for scenarios requiring robust outdoor networking solutions. Their moisture-resistant properties make them ideal for connecting outdoor devices such as Wi-Fi access points or security cameras. In industrial environments, these cables can withstand exposure to chemicals and harsh weather, providing reliable data transmission in factories and chemical plants. Additionally, they prove beneficial in telecommunication infrastructures, particularly in rural areas where long distances and adverse environmental conditions challenge standard cables. These cables' versatility in overcoming environmental obstacles ensures their widespread application in various demanding networking projects.

Product After-Sales Service

Aston Cable ensures customer satisfaction through comprehensive after-sales service, including technical support and troubleshooting assistance. Customers can rely on prompt responses from our experienced team for any inquiries or issues related to our Cat6 jelly filled cables.

Product Transportation

Our Cat6 jelly filled cables are packaged securely to withstand transportation, ensuring they arrive in optimal condition. We offer flexible shipping options, including sea and air freight, to meet our customers' logistical needs.

Product Advantages

- High moisture resistance for durability in outdoor conditions

- UV-protected outer jacket for extended lifespan

- Supports high-speed data transfer with minimal interference

Product FAQ

- What makes Cat6 jelly filled cables suitable for outdoor use? The jelly filling provides superior moisture resistance, essential for outdoor installations exposed to rain and humidity.

- Can these cables handle chemical exposure? Yes, the robust outer jacket resists various chemicals, making these cables suitable for industrial environments.

- What is the typical lifespan of these cables in outdoor settings? With proper installation, these cables can last several years, thanks to their durable construction and resistance to environmental factors.

- Do these cables support high-speed data transfer? Absolutely, they maintain the performance standards of regular Cat6 cables, supporting speeds up to 1 Gbps.

- Are these cables easy to install? Yes, their design facilitates straightforward installation, even in challenging environments.

- What is the minimum order quantity? The MOQ for our Cat6 jelly filled cables is 30 km.

- Is there a warranty for these cables? Yes, we offer a comprehensive warranty covering manufacturing defects and performance standards.

- Are custom lengths available? We can accommodate custom length requests to suit specific project needs.

- Do you offer technical support post-purchase? Our dedicated team offers ongoing technical support to ensure optimal cable performance.

- How does UV protection benefit the cable? The UV-resistant jacket protects the cable from sunlight damage, enhancing its longevity in outdoor applications.

Product Hot Topics

- Ensuring Data Integrity with Cat6 Jelly Filled Cables: In an era where data integrity is paramount, using a reliable manufacturer like Aston for Cat6 jelly filled cables guarantees robust network solutions that withstand environmental challenges. These cables provide consistent performance, making them a preferred choice in various applications requiring outdoor connectivity.

- The Role of Cat6 Jelly Filled Cables in Industrial Networking: Industrial environments demand cables that can withstand harsh conditions. Aston's Cat6 jelly filled cables, manufactured with durability in mind, offer chemical and moisture resistance, ensuring stable data transmission even in the most challenging settings.

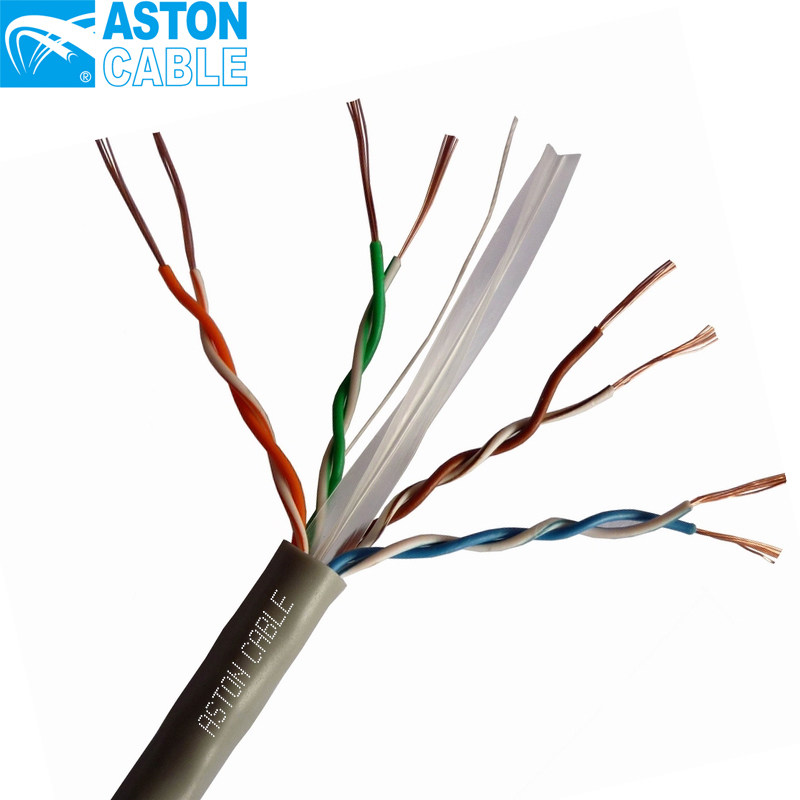

Image Description