Product Main Parameters

| Parameter | Details |

|---|---|

| Conductor Material | Bare Copper/CCA |

| Conductor Size | 24AWG |

| Insulation | HDPE |

| Outer Jacket | PVC PE |

| Flame Retardant | IEC Compliant |

| Shielding | None |

| Origin | Hangzhou, Zhejiang |

Common Product Specifications

| Specification | Details |

|---|---|

| MOQ | 50KM |

| Daily Output | 200KM |

| Annual Supply | 25000KM |

| Delivery Port | Ningbo |

| Certifications | SGS, CE, ROHS, ISO9001 |

Product Manufacturing Process

The manufacturing process for Cat7 cables involves several critical steps to ensure high performance and reliability. The process begins with the selection of high-quality raw materials, primarily copper or copper-clad aluminum (CCA) for conductors. The conductors are precisely twisted into pairs to minimize electromagnetic interference (EMI) and crosstalk, adhering to strict standards. Advanced extrusion techniques are employed to apply primary insulation using high-density polyethylene (HDPE) over the twisted pairs. A double jacket is then added, with a layer of PVC for flexibility and an outer layer of PE for enhanced UV resistance, especially for outdoor applications. Quality control tests, including checks for impedance, return loss, and Near End Crosstalk (NEXT), are conducted at multiple stages to ensure compliance with international standards. The final product is packaged for transportation, maintaining optimal conditions to avoid any physical or chemical damage.

Product Application Scenarios

Cat7 cables are engineered for high-performance networking environments where reliable and fast data transmission is crucial. These cables are highly suitable for installation in data centers, server rooms, and enterprise networks that require high-speed and low-latency connections. Their robust construction, featuring superior shielding and double jackets, makes them an excellent choice for outdoor installations vulnerable to UV exposure and mechanical wear. Cat7 cables meet the demands of modern applications such as 4K video streaming, online gaming, and cloud computing, where large bandwidth and minimal data loss are essential. Additionally, their backward compatibility with earlier Ethernet standards ensures seamless integration into existing infrastructures. Companies focused on digital transformation and infrastructure upgrades rely on Cat7 suppliers to deliver cabling solutions that offer durability and future-proofing.

Product After-Sales Service

- Technical Support: 24/7 customer service for installation and troubleshooting.

- Warranty: Limited lifetime warranty covering defects and performance issues.

- Replacement Policy: Free replacement for defective cables within warranty period.

- Installation Guides: Detailed documentation and video tutorials available.

Product Transportation

- Packaging: Anti-static, moisture-proof packaging to preserve cable integrity.

- Logistics: Fast and reliable shipping through reputed courier partners.

- Tracking: Real-time tracking updates available for all shipments.

Product Advantages

- Enhanced Performance: Supports high-speed data transmission up to 10 Gbps.

- Robust Construction: Double jackets for improved durability and UV resistance.

- Future-Proof: Ideally suited for emerging network technologies and applications.

- Compatibility: Backward compatible with Cat6 and Cat5e infrastructures.

- Cost-Effective: Competitive pricing with high performance makes it a valuable choice.

Product FAQ

- What is the main benefit of using Cat7 cables? Cat7 cables provide superior shielding and support high-speed data transfers, making them ideal for demanding networking environments.

- Can Cat7 cables be used outdoors? Yes, with double jackets of PVC and PE, Cat7 cables are designed to withstand outdoor conditions including UV exposure and temperature variations.

- Are Cat7 cables compatible with existing Cat6 networks? Absolutely, Cat7 cables use GG45 connectors that are backward compatible with RJ45 used by Cat6 and Cat5e.

- How do I choose between copper and CCA conductors? Copper provides better conductivity and performance while CCA is more cost-effective. It depends on your budget and performance needs.

- What is the MOQ for ordering Cat7 cables? The minimum order quantity is 50KM, suitable for projects of various scales.

- How long does shipping typically take? Depending on the destination, delivery can take 5-15 business days after order confirmation.

- Is there a warranty for Cat7 cables? Yes, all cables come with a limited lifetime warranty covering manufacturing defects.

- What certifications do Cat7 cables have? They are certified by SGS, CE, ROHS, and ISO9001, ensuring high quality and compliance.

- Can Cat7 cables support power over Ethernet (PoE)? Yes, they are compatible with PoE standards, providing both data and power transmission.

- What is the daily production capacity of Cat7 cables? The production capacity is approximately 200KM per day, allowing us to meet high demand.

Product Hot Topics

- Advantages of Double Jacketed Cat7 Cables

Cat7 suppliers emphasize the importance of double jacketing for outdoor cables, as it significantly enhances durability and protects against harsh environmental elements. The dual layering of PVC and PE offers excellent UV protection and mechanical strength, making these cables a preferred choice for outdoor network setups. This innovation not only extends the lifespan of the cables but also ensures reliable data transmission even under challenging conditions, reinforcing their appeal for high-performance network installations. - Choosing the Right Cat7 Cable for Your Needs

When selecting Cat7 cables, it is crucial to consider factors such as conductor material, shielding, and jacket type. Leading suppliers provide both copper and CCA options, each catering to different performance requirements and budget constraints. Double jackets, featuring PVC and PE, are recommended for outdoor use due to their enhanced protective qualities. By understanding these aspects, customers can make informed decisions, ensuring optimal performance and longevity of their networking infrastructure.

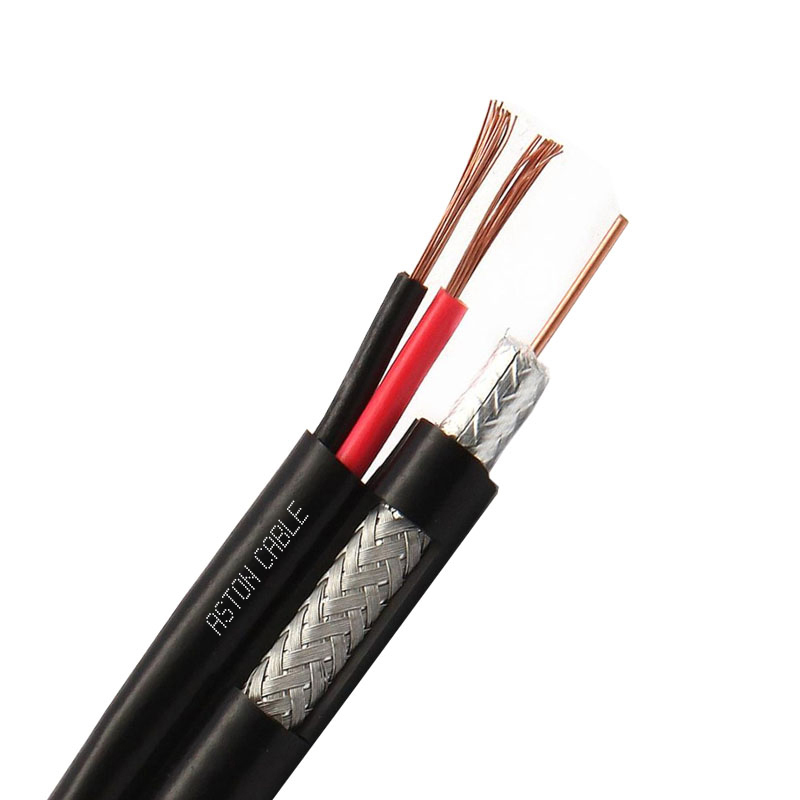

Image Description