Product Main Parameters

| Parameter | Specification |

|---|---|

| Conductor | 24 AWG, Bare Copper/CCA |

| Insulation | HDPE |

| Core | 4 Pairs Stranded |

| Outer Jacket | PVC & PE or PVC & PVC |

| Color | Customized |

| Shielding | None |

Common Product Specifications

| Specification | Details |

|---|---|

| Daily Output | 200KM |

| MOQ | 50KM |

| Certification | SGS, CE, RoHS, ISO9001 |

| Origin | Hangzhou, Zhejiang, China |

| Brand | ASTON or OEM |

| Delivery Port | Ningbo |

| Supply Ability | 25000KM/Per Year |

Product Manufacturing Process

Cat5e gel-filled cables undergo a rigorous manufacturing process to ensure durability and performance for outdoor use. The process begins with the selection of high-quality copper or CCA conductors. These conductors are either solid or stranded to enhance durability and flexibility. Each conductor is insulated using high-density polyethylene (HDPE) to prevent electrical interference and maintain signal integrity.

The insulated conductors are then twisted into pairs to minimize electromagnetic interference (EMI) and crosstalk. The twisted pairs are gel-filled to create a waterproof barrier, protecting the internal structure from moisture and other environmental factors. This is particularly crucial for outdoor installations.

The core of the cable is then encased in double outer jackets, usually made from a combination of PVC and PE. PVC provides flexibility and ease of installation, while PE offers UV resistance and hardness, making it suitable for harsh outdoor conditions. The final product is tested rigorously to ensure it meets all performance and safety standards, including ISO9001, ISO14001, RoHS, and CE certifications.

Product Application Scenarios

Cat5e gel-filled cables are highly versatile and suitable for a variety of application scenarios. They are ideal for outdoor installations where moisture and harsh environmental conditions are a concern. This makes them perfect for connecting network devices between buildings or to external network access points. The gel filling provides a waterproof barrier, ensuring reliable performance even in wet conditions.

These cables are also suitable for direct burial without additional conduits, thanks to their robust water-resistant properties. This is particularly beneficial for rural or remote areas where telecommunication companies need to provide internet and network services. In industrial environments, the cables withstand exposure to moisture, chemicals, and temperature extremes, making them reliable for harsh conditions.

In addition to outdoor and industrial applications, these cables are also used in residential settings for outdoor networking needs. Their durability and performance capabilities make them a preferred choice for a wide range of networking applications.

Product After-sales Service

We offer comprehensive after-sales service for our Cat5e gel-filled cables. Our customer service team is available to assist with any issues or questions regarding installation, performance, and maintenance. We provide technical support and troubleshooting to ensure optimal performance of our products. Warranty and replacement services are also available to address any manufacturing defects or performance issues. Customer satisfaction is our priority, and we strive to provide the best support to ensure a seamless experience with our products.

Product Transportation

Our Cat5e gel-filled cables are packaged using standard export packaging to ensure safe transportation. We collaborate with reliable logistics partners to ensure timely and secure delivery of our products. Orders are shipped from the Ningbo port, and we accommodate various shipping options to meet the specific needs and timelines of our customers. Our packaging is designed to protect the cables from damage during transit, ensuring they reach their destination in optimal condition.

Product Advantages

- Moisture Resistance: Gel filling prevents water ingress, ensuring reliable performance in wet conditions.

- Durability: Double jackets (PVC & PE) offer enhanced durability, making the cables suitable for harsh environments.

- Enhanced Performance: Gel filling maintains physical integrity, providing consistent performance over time.

- Versatility: Suitable for a wide range of applications, including outdoor, industrial, and residential networking.

- Compliance: Meets international standards such as ISO9001, ISO14001, RoHS, and CE certifications.

Product FAQ

- What is the MOQ for Cat5e gel-filled cables?

The minimum order quantity (MOQ) for our Cat5e gel-filled cables is 50km. - What are the key features of Cat5e gel-filled cables?

Key features include moisture resistance, durability, enhanced performance, and versatility for various applications. - What materials are used in the construction of these cables?

Our Cat5e gel-filled cables use 24 AWG copper/CCA conductors, HDPE insulation, and double jackets made of PVC and PE. - Are these cables suitable for outdoor use?

Yes, the double jackets (PVC & PE) and gel filling make them ideal for outdoor use, providing UV resistance and protection against harsh conditions. - What certifications do these cables have?

Our Cat5e gel-filled cables are SGS, CE, RoHS, and ISO9001 certified. - Can these cables be buried directly?

Yes, they are suitable for direct burial without additional conduits due to their water-resistant properties. - How do I handle the gel filling during installation?

Special handling and termination techniques are required. It is advisable to use gloves and appropriate tools to manage the gel. - What is the daily output capacity for these cables?

Our factory produces 200KM of Cat5e gel-filled cables daily. - Where are these cables manufactured?

They are manufactured in Hangzhou, Zhejiang, China. - What is the delivery port for these cables?

The delivery port for these cables is Ningbo.

Product Hot Topics

Why Choose Cat5e Gel-Filled Cables from China?

Choosing Cat5e gel-filled cables from China offers several advantages, including cost-effectiveness, advanced manufacturing technology, and adherence to international standards. Our cables are manufactured with high-quality materials and undergo rigorous testing to ensure reliability and performance. With over 20 years of experience in cable production, Aston Cable factory in Hangzhou, China, provides professional solutions tailored to meet diverse networking needs. Our cables are RoHS, CE, and ISO9001 certified, ensuring compliance with global standards. Additionally, the robust double jackets and gel filling make these cables suitable for harsh environmental conditions, providing long-lasting performance and durability.

The Importance of Moisture Resistance in Outdoor Cables

Moisture resistance is a critical factor for outdoor cables to ensure reliable performance and longevity. Cat5e gel-filled cables from China are designed with a gel filling that acts as a waterproof barrier, protecting the internal conductors from water ingress and corrosion. This feature is essential for outdoor installations where cables are exposed to rain, humidity, and other harsh environmental conditions. The combination of double jackets (PVC & PE) further enhances the durability, making these cables ideal for direct burial and industrial applications. By preventing moisture-related damage, these cables maintain signal integrity and provide consistent performance, making them a preferred choice for outdoor networking needs.

Understanding the Construction of Cat5e Gel-Filled Cables

Cat5e gel-filled cables are constructed with high-quality materials to ensure durability and performance in outdoor environments. The conductors are made of 24 AWG copper or CCA and are insulated with high-density polyethylene (HDPE) to prevent electrical interference. The twisted pairs of conductors are gel-filled to create a waterproof barrier, protecting them from moisture and other environmental factors. The outer jacket consists of two layers—inner PVC and outer PE—providing flexibility, UV resistance, and hardness. This construction ensures that the cables withstand harsh conditions, making them suitable for outdoor, industrial, and direct burial applications.

How to Install Cat5e Gel-Filled Cables

Installing Cat5e gel-filled cables requires special handling and techniques due to the presence of gel filling. It is advisable to use gloves and appropriate tools to manage the gel during installation. The cables need to be properly grounded and shielded to ensure compliance with local electrical codes and standards. The robust double jackets (PVC & PE) make these cables ideal for outdoor installations, providing protection against UV radiation, moisture, and physical abrasion. Proper installation techniques ensure optimal performance and longevity of the cables in various environments.

The Benefits of Double Jackets in Outdoor Cables

Double jackets in outdoor cables provide enhanced protection and durability, making them suitable for harsh environmental conditions. The inner PVC jacket offers flexibility and ease of installation, while the outer PE jacket provides UV resistance and hardness. This combination ensures that the cables withstand exposure to sunlight, moisture, chemicals, and physical abrasion. The double jackets also prevent the outer layer from sticking to the insulation during manufacturing, ensuring the integrity of the cable structure. These benefits make double-jacketed Cat5e gel-filled cables a reliable choice for outdoor networking applications.

The Role of Gel Filling in Cat5e Cables

Gel filling in Cat5e cables plays a crucial role in providing moisture resistance, ensuring reliable performance in wet conditions. The gel acts as a waterproof barrier, preventing water ingress and protecting the internal conductors from corrosion and signal degradation. This feature is particularly important for outdoor and direct burial applications where cables are exposed to rain, humidity, and other harsh environmental factors. By maintaining the physical integrity of the cable structure, gel filling ensures consistent performance over time, making Cat5e gel-filled cables suitable for a wide range of networking needs.

Comparing Cat5e Gel-Filled Cables to Standard Cat5e Cables

Cat5e gel-filled cables offer several advantages over standard Cat5e cables, particularly for outdoor and industrial applications. The primary difference lies in the gel filling, which provides a waterproof barrier, protecting the internal conductors from moisture and environmental factors. This makes gel-filled cables more suitable for harsh conditions, ensuring reliable performance and durability. Additionally, the double jackets (PVC & PE) enhance the overall robustness of the cables, making them resistant to UV radiation, physical abrasion, and chemicals. Standard Cat5e cables, while suitable for indoor use, may not offer the same level of protection and performance in challenging environments.

Key Considerations for Choosing Outdoor Networking Cables

When choosing outdoor networking cables, several key considerations should be kept in mind. Moisture resistance is crucial to prevent water ingress and ensure reliable performance in wet conditions. Durability is also important, as the cables need to withstand exposure to UV radiation, physical abrasion, and chemicals. Double jackets (PVC & PE) provide enhanced protection and make the cables suitable for harsh environments. Gel filling further enhances moisture resistance, ensuring consistent performance over time. Compliance with international standards (e.g., RoHS, CE, ISO9001) is also essential to ensure quality and safety. By considering these factors, you can choose the right outdoor networking cables for your specific needs.

The Complexity of Installing Gel-Filled Cables

Installing gel-filled cables can be more complex compared to standard indoor cables due to the presence of gel filling. Special handling and termination techniques are required to manage the gel during installation. It is advisable to use gloves and appropriate tools to avoid any mess and ensure proper termination. Additionally, the cables might need to be properly grounded and shielded to ensure compliance with local electrical codes and standards. Despite the complexity, the added benefits of moisture resistance and durability make gel-filled cables a preferred choice for outdoor and industrial applications. Proper installation techniques ensure optimal performance and longevity of the cables.

Choosing the Right Cable Structure for Your Market

Choosing the right cable structure for your market depends on several factors, including the specific environmental conditions and performance requirements. Double jackets (PVC & PE) provide enhanced protection and durability, making them suitable for outdoor and industrial applications. However, they also come with higher costs and larger cable diameters. For indoor applications, single PVC jackets may be more suitable due to their flexibility and ease of installation. Understanding the specific needs of your market and the environmental conditions can help you make an informed decision on the most suitable cable structure.

The Importance of Compliance with International Standards

Compliance with international standards such as RoHS, CE, ISO9001, and others is crucial to ensure the quality, safety, and performance of networking cables. Cat5e gel-filled cables from China are manufactured in adherence to these standards, providing reliable and high-quality products. Compliance with these standards ensures that the cables meet global requirements for performance, durability, and safety, making them suitable for various applications. By choosing cables that comply with international standards, you can ensure consistent performance and reliability across different environments and conditions.

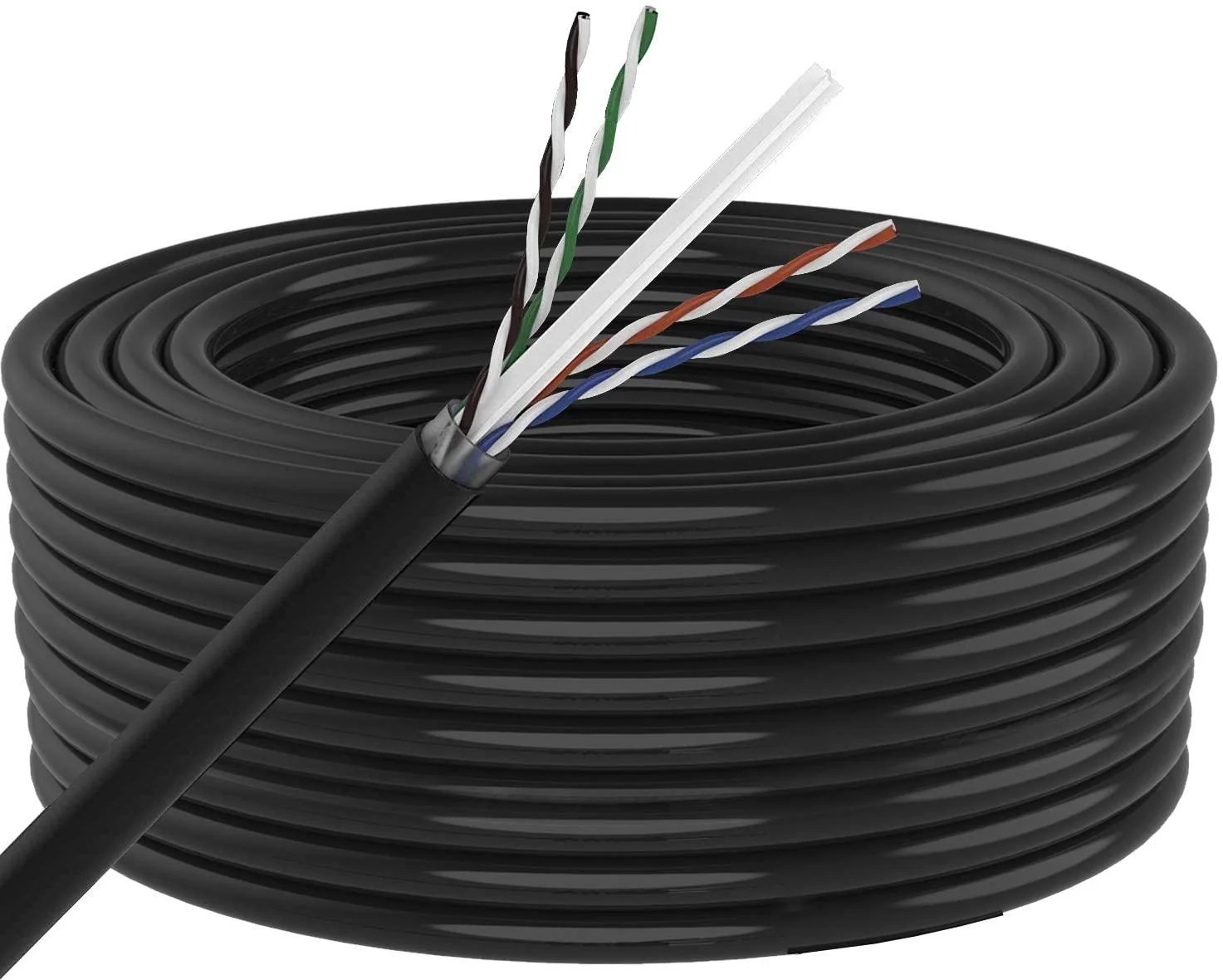

Image Description