Product Main Parameters

| Parameter | Description |

|---|---|

| Material | Copper Clad Aluminum (CCA) |

| Diameter Range | 0.12mm-3.0mm |

| Color | Copper |

| MOQ | 1000KG |

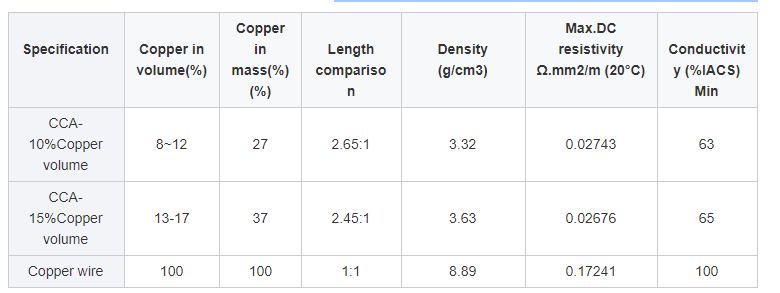

Common Product Specifications

| Specification | Details |

|---|---|

| Place of Origin | China |

| Certification | SGS, CE, ROHS, ISO9001 |

| Daily Output | 200KM |

| Minimum Order Quantity | 30km |

| Packaging | Normal export packaging |

Product Manufacturing Process

Copper Clad Aluminum manufacturing involves a process where an aluminum core is coated with a thin layer of copper. This technique combines aluminum's lightweight properties with copper's electrical conductivity, offering a balanced solution for cost-effective electrical conduction. Research studies highlight the efficient bonding process, which ensures that the electrical performance is maintained while reducing material costs. The process also includes controls to ensure durability and resistance to environmental factors, such as oxidation and corrosion, aligning with industry standards and meeting global certification requirements.

Product Application Scenarios

Copper Clad Aluminum vs Copper Wire showcases distinct applications. CCA is favored in cost-sensitive projects and weight-critical scenarios, such as in residential wiring, speaker cables, and CATV coaxial cables. On the other hand, copper wire is preferred for high-frequency, performance-demanding applications such as power generation, telecommunications, and high-stakes electronics manufacturing. Studies have demonstrated that while CCA may not match copper's conductivity and reliability, its economic and weight-saving benefits make it an attractive alternative, particularly in non-critical applications.

Product After-Sales Service

We provide comprehensive after-sales support for our CCA products. This includes a warranty for manufacturing defects, technical support for installation and usage, and readily available customer service for any queries or assistance required post-purchase. Our team is committed to ensuring client satisfaction by addressing any concerns promptly and professionally.

Product Transportation

The product is packaged in durable materials to ensure safe transportation. Depending on the quantity, we offer flexible shipping options via sea or air from Ningbo port. Our logistics team coordinates and tracks shipments to ensure timely delivery.

Product Advantages

- Cost-effective alternative to copper

- Lightweight and easy to handle

- Meets various global certifications

- Various applications in residential and commercial settings

- Long-lasting performance in indoor environments

Product FAQ

- What is CCA? CCA stands for Copper Clad Aluminum, a material that combines the cost-effectiveness of aluminum with the conductivity of copper, offering a balanced solution in electrical applications.

- Why choose CCA over copper wire? CCA is chosen over copper for its cost and weight benefits without compromising significantly on performance, especially in less critical applications.

- Is CCA as conductive as copper? No, CCA is less conductive than pure copper, but its performance is sufficient for many residential and commercial applications.

- Where is CCA typically used? CCA is widely used in residential wiring, speaker cables, CATV coaxial cables, and other applications where cost and weight are primary considerations.

- Is CCA durable? Yes, while not as robust as copper, CCA offers good durability due to its copper coating which provides some protection against oxidation.

- What are the available sizes for CCA wire? CCA wire is available in sizes ranging from 0.12mm to 3.0mm, catering to diverse application needs.

- How does CCA respond to environmental factors? The copper coating on CCA provides limited resistance to environmental factors, making it suitable for indoor use.

- What certifications does your CCA wire have? Our CCA wire is certified by SGS, CE, ROHS, and ISO9001, ensuring compliance with international quality standards.

- Can I use CCA for telecommunications? Yes, CCA is used in various telecommunications applications, though copper might be preferred for higher performance needs.

- How do I purchase CCA wire? You can contact our sales team for orders, with flexible MOQ options and competitive pricing based on your project requirements.

Product Hot Topics

1. CCA vs Copper Wire: A Cost-Effective Debate in China

The debate between copper clad aluminum vs copper wire has long been a topic of interest in China, particularly in the context of balancing cost and performance. With CCA offering a cheaper alternative for budget-conscious projects, it has gained popularity in various applications where high conductivity is not critical, yet it still provides adequate performance. In contrast, copper wire remains the preferred choice for its unmatched conductivity and reliability, especially in high-stakes environments. Industries continue to weigh these factors to choose the appropriate conductor for their specific needs.

2. Weight Considerations: China’s Preference for Lighter Materials

As industries increasingly prioritize weight-saving measures, the choice between copper clad aluminum vs copper wire becomes pivotal, especially in sectors like aerospace and large-scale data cabling in China. The lightweight nature of CCA offers significant advantages in these scenarios, where the supporting infrastructure must be minimal. With aluminum's inherent lighter weight compared to copper, CCA emerges as an attractive candidate for applications that can sacrifice a bit of conductivity for the much-needed weight benefits. This trend underscores the importance of material selection based on project-specific requirements.

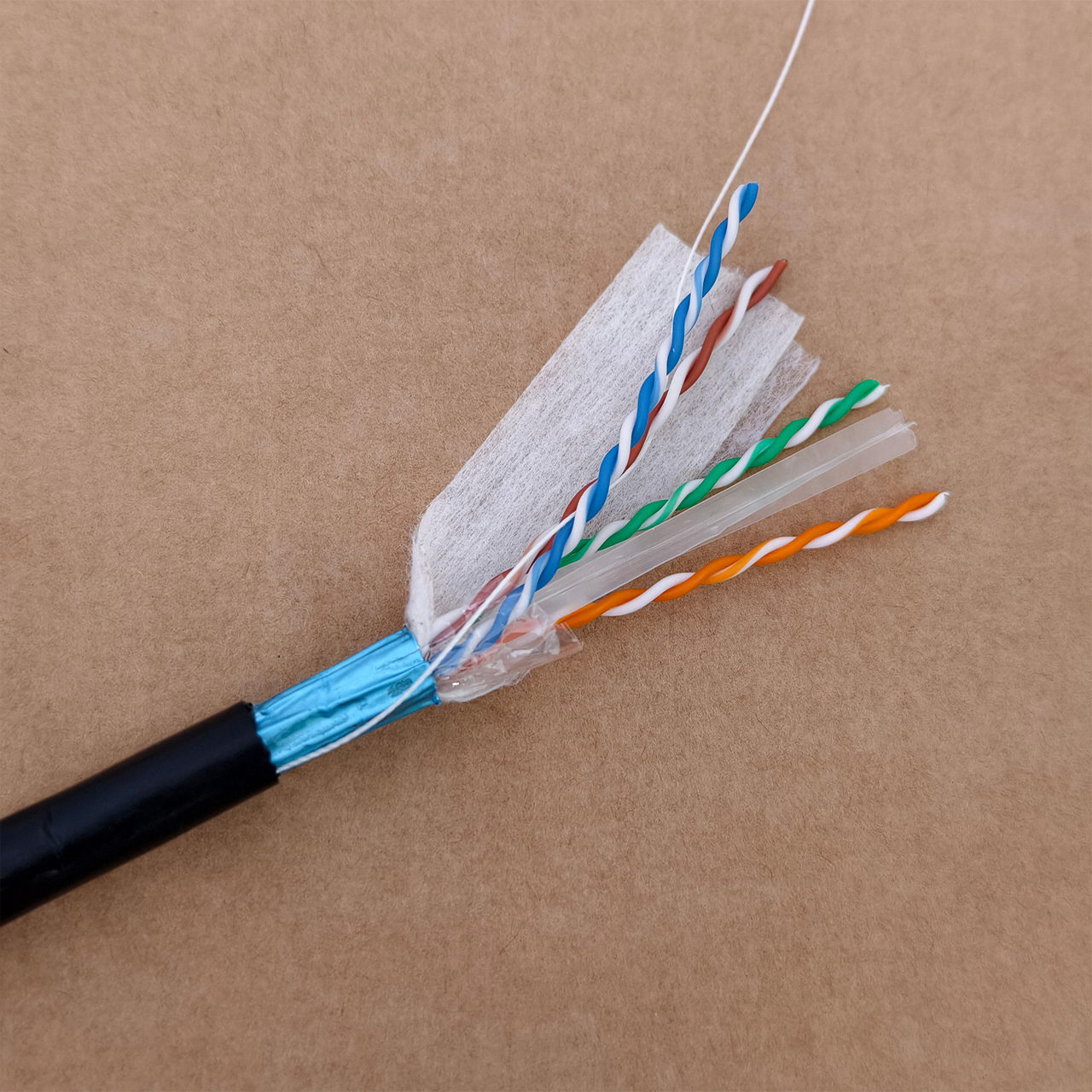

Image Description