Product Main Parameters

| Item | Details |

|---|---|

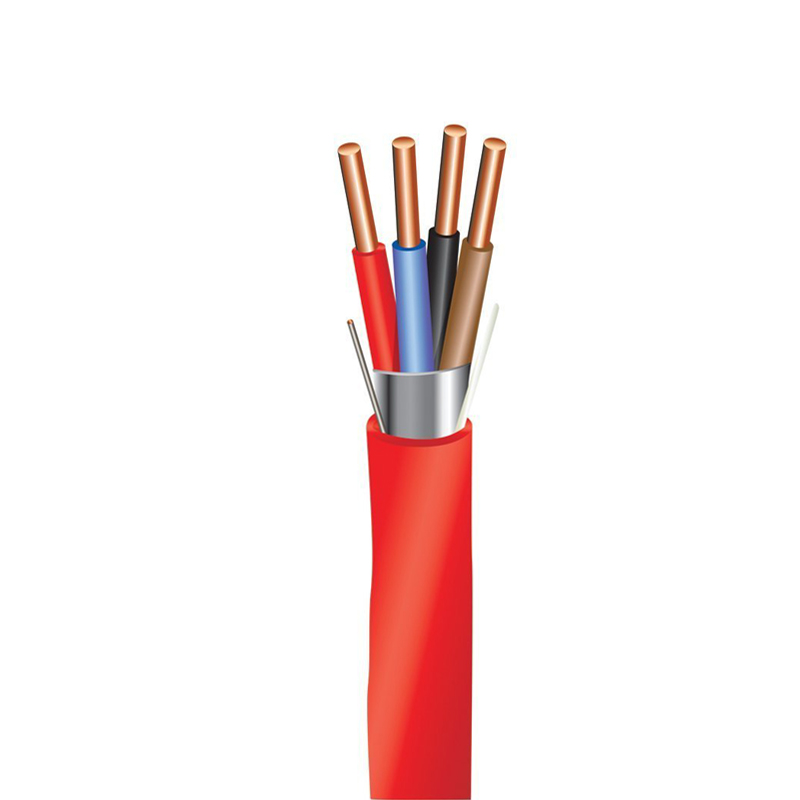

| Conductor | 18 AWG Copper-Clad Aluminum |

| Insulation | Gas Injected Polyethylene |

| Jacket Material | PVC |

| Cable Diameter | 0.265'' Nominal |

| Weight | 35 lbs/1000 ft Nominal |

Common Product Specifications

| Frequency | Attenuation (dB/100m) |

|---|---|

| 5 MHz | 1.7 |

| 50 MHz | 5.0 |

| 200 MHz | 8.7 |

| 400 MHz | 12.8 |

| 800 MHz | 18.0 |

Product Manufacturing Process

The manufacturing of copper clad aluminum wire involves a metallurgical bonding process known as cladding or electroplating. A thin layer of copper is bonded to an aluminum core, resulting in a wire that retains high electrical conductivity like pure copper while being lighter and more cost-effective. This type of wire is particularly advantageous in the telecommunications industry, where efficient signal transmission and reduced costs are essential. Studies have shown that copper clad aluminum wire maintains a balance of conductivity, flexibility, and durability, making it highly suitable for widespread electrical and communication applications.

Product Application Scenarios

Copper clad aluminum wire is widely used in telecommunications, automotive, and residential wiring due to its excellent electrical properties and cost-effectiveness. In the telecommunications sector, it serves as a reliable medium for data transmission, supporting high speed internet and cable TV services. The automotive industry benefits from its lightweight properties, contributing to fuel efficiency and reduced vehicle weight. In residential applications, it is used where a balance of performance and cost savings is necessary. Ongoing research suggests that with proper installation and usage scenarios, China copper clad aluminum wire can outperform traditional all-copper solutions in specific contexts.

Product After-Sales Service

We offer comprehensive after-sales support for our copper clad aluminum wire products, ensuring that our customers receive assistance with installation, troubleshooting, and maintenance. Our dedicated customer service team is available to answer any questions and provide guidance on optimal product use. We also offer a warranty that covers manufacturing defects, ensuring peace of mind and product satisfaction.

Product Transportation

Our China copper clad aluminum wire products are carefully packaged to ensure safe delivery to your location. We employ standard export packaging that protects against environmental factors during transportation. Orders are shipped from our factory in Hangzhou, China, with delivery options via Ningbo Port. We strive to provide timely and reliable shipping to meet the needs of our customers.

Product Advantages

- Cost-effective solution with high performance for various applications.

- Lightweight and easy to install, reducing labor costs and installation time.

- Excellent corrosion resistance due to the copper cladding, extending product lifespan.

- Suitable for a wide range of environments and applications, from telecommunications to automotive.

Product FAQ

- What are the main benefits of using copper clad aluminum wire?

Copper clad aluminum wire offers several benefits, including cost-effectiveness, lightweight properties, good electrical conductivity, and corrosion resistance. These features make it a popular choice for applications where budget and efficiency are crucial. - Can copper clad aluminum wire be used for high-load applications?

While copper clad aluminum wire provides decent conductivity, it is not as conductive as pure copper wires. Therefore, it may not be suitable for high-load applications where maximum conductivity is required. It is important to evaluate the specific electrical requirements of your application before choosing this wire type. - Is copper clad aluminum wire safe for use in residential wiring?

Yes, copper clad aluminum wire can be used in residential wiring, especially in situations where cost savings are a priority and the electrical load requirements are within the wire's capabilities. It is important to ensure compliance with local building codes and standards. - How does the manufacturing process affect wire performance?

The manufacturing process involves cladding or electroplating a layer of copper onto an aluminum core. This process enhances the wire's conductivity while maintaining its lightweight and cost-effective nature. Properly manufactured copper clad aluminum wire exhibits reliable performance across various applications. - What precautions should be taken when installing copper clad aluminum wire?

During installation, it is important to ensure secure connections and consider expansion and contraction due to temperature changes. Proper installation techniques will help prevent loose connections and maintain stable electrical performance over time.

Product Hot Topics

- Copper Clad Aluminum: The Future of Electrical Wiring

The use of copper clad aluminum wire is gaining traction in various industries due to its cost-effectiveness and reliable performance. With advancements in manufacturing techniques, this wire type offers a compelling alternative to traditional copper wires, especially in mass production scenarios. - Why Choose Copper Clad Aluminum for Telecommunications?

Telecommunications infrastructure demands efficient and cost-effective solutions. Copper clad aluminum wire meets these needs by providing excellent signal quality and transmission capabilities at a lower cost compared to all-copper counterparts. Its corrosion resistance and lightweight properties make it ideal for large-scale deployments.

Image Description