Product Main Parameters

| Parameter | Description |

|---|---|

| Conductor | Bare Copper 23AWG |

| Insulation | Cross-linked Polyethylene (XLPE) |

| Fire-Resistant Layer | Mica Tape Barrier |

| Sheath | Low-Smoke Zero Halogen (LSZH) |

Common Product Specifications

| Specification | Detail |

|---|---|

| Origin | China |

| Standard Compliance | IEC 60331, BS 6387, EN 50200 |

| Length | 305m/roll |

| Colors | Customizable |

Product Manufacturing Process

Fire-resistant cables are engineered to maintain circuit integrity under high-temperature fire conditions, making them indispensable for critical safety. The manufacturing process begins by selecting high-quality copper or aluminum for the conductors, ensuring maximum conductivity and durability. Insulation is applied using materials like XLPE or EPR, known for withstanding extreme heat without degradation. A critical component is the fire-resistant layer, typically consisting of mica tape, which serves as an effective barrier against flames. The outer sheath, often made from LSZH compounds, minimizes toxic gas emission and smoke production. Manufacturing follows stringent quality control measures to comply with international standards such as IEC 60331, ensuring reliability and performance consistency. Together, these elements form a robust cable capable of supporting emergency systems in high-risk environments.

Product Application Scenarios

Fire-resistant cables are crucial in environments where maintaining operational integrity during fires is critical. They are extensively used in emergency systems, supporting fire alarms, smoke detectors, and emergency lighting to ensure seamless operation during evacuations in places like hospitals, airports, and other critical infrastructure. In high-occupancy buildings such as shopping malls and cinemas, these cables facilitate safe evacuations by ensuring essential systems remain functional. Additionally, in underground installations, tunnels, and other areas with limited evacuation pathways, fire-resistant cables provide reliable communication and lighting to aid in emergency responses. Their role in containing fire spread and reducing toxic emissions is vital, contributing to enhanced safety in various complex scenarios.

Product After-sales Service

At Aston Cable, customer satisfaction does not end with a purchase. We offer comprehensive after-sales service, including product installation guidance, troubleshooting, and technical support to ensure optimal cable performance. Our dedicated customer service team is available to assist with any inquiries or issues that may arise, providing timely and effective solutions. Warranty coverage is provided, guaranteeing the quality and reliability of our fire-resistant cables, aligned with our commitment to exceptional service.

Product Transportation

Our logistics team ensures the safe and timely delivery of fire-resistant cables worldwide. Each cable is securely packaged in compliance with international shipping standards to prevent damage during transit. Customers can choose from various delivery options, including express shipping for urgent requirements. Aston Cable partners with reputable logistics providers, ensuring efficient transportation from our China manufacturing facility to your location, regardless of the destination.

Product Advantages

- Superior Safety: Engineered to maintain circuit integrity under fire conditions.

- Compliance: Meets IEC, BS, and EN standards for fire resistance.

- Reliability: Designed for critical applications in emergency systems.

- Durability: Features high-quality materials like XLPE and mica tape.

- Environmentally Friendly: LSZH sheath minimizes toxic emissions.

Product FAQ

- What is the primary use of fire-resistant cables?China's fire-resistant cables are primarily used in systems where maintaining function during a fire is crucial, such as emergency lighting, alarms, and communication systems.

- Are these cables compliant with international standards?Yes, our fire-resistant cables adhere to standards like IEC 60331, BS 6387, and EN 50200, ensuring their reliability and performance.

- Can these cables be used in high-temperature environments?Absolutely, they are designed to withstand extreme temperatures without losing integrity, thanks to materials like XLPE and mica.

- What are the packaging options for these cables?Fire-resistant cables are packaged in secure rolls to protect them during transit, with customizable options available based on customer needs.

- Is technical support available for cable installation?Yes, Aston Cable offers technical support for installation and troubleshooting to ensure optimal performance of our fire-resistant cables.

- What materials are used in the construction of these cables?The primary materials include bare copper for conductivity, XLPE for insulation, and mica tapes for fire resistance, with an LSZH outer sheath.

- How do fire-resistant cables differ from fire-retardant cables?Fire-resistant cables maintain operational integrity during a fire, while fire-retardant cables prevent fire spread but may not function during a fire.

- Where is the origin of Aston fire-resistant cables?All Aston fire-resistant cables are manufactured at our facility in Hangzhou, China.

- What is the lifespan of these cables?With high-quality materials and robust construction, these cables are designed for extended use in critical applications.

- Are customization options available?Yes, Aston Cable offers customization in lengths, colors, and branding to meet specific customer requirements.

Product Hot Topics

- Why is fire resistance crucial in cables?Fire resistance in cables ensures that essential systems remain operational during emergencies, providing the necessary support to safely evacuate and protect lives and assets. In high-risk environments, maintaining electrical integrity can significantly impact the outcome of a fire event, making fire-resistant cables an indispensable safety feature in modern infrastructure.

- How do fire-resistant cables contribute to safety?Fire-resistant cables play a vital role in enhancing safety by preventing circuit failures during fires, allowing emergency systems to function and supporting evacuation and firefighting efforts. They are crucial in containing fire spread and reducing toxic smoke emissions, contributing to a safer environment.

- Does the installation of fire-resistant cables require special conditions?While fire-resistant cables are designed to withstand extreme conditions, proper installation is key to maximizing their efficacy. Following manufacturer guidelines and industry standards ensures these cables deliver optimal performance in maintaining circuit integrity during fires.

- Environmental benefits of using LSZH sheath in cables.Low-Smoke Zero Halogen (LSZH) sheaths in cables drastically reduce the emission of toxic fumes and smoke during fires, enhancing safety for occupants and firefighters. This environmentally friendly attribute makes LSZH-sheathed cables a preferred choice in modern construction.

- What industries benefit most from fire-resistant cables?Industries like healthcare, aviation, power generation, and high-occupancy buildings benefit greatly from fire-resistant cables due to their critical need for reliable power and communication during emergencies. These cables support continuity in essential services, enhancing safety and operational integrity.

- How do fire-resistant cables help in tunnel and underground installations?In tunnels and underground facilities where evacuation routes are limited, fire-resistant cables ensure continuous communication and lighting, aiding both evacuation and emergency response efforts. Their robust design withstands the unique challenges of such environments.

- Innovation in fire-resistant cable technology.Ongoing advancements in materials and manufacturing processes continue to enhance the performance and reliability of fire-resistant cables. Innovations focus on improving temperature tolerance, durability, and ease of installation, ensuring these cables meet evolving safety and performance standards.

- The role of standards in fire-resistant cable manufacturing.Compliance with international standards like IEC 60331 and BS 6387 ensures that fire-resistant cables meet strict performance criteria. These standards guide manufacturers in producing cables that deliver reliable performance under fire conditions, safeguarding lives and infrastructure.

- Comparing fire-resistant and traditional cables: What are the cost implications?While fire-resistant cables generally cost more due to their specialized materials and construction, their ability to maintain functionality during fires represents a crucial investment in safety, providing significant advantages over traditional cables in critical applications.

- The future of fire-resistant cable technology.As building codes and safety requirements evolve, fire-resistant cable technology will continue to adapt, offering enhanced performance and new capabilities. Future developments may include materials with even higher temperature thresholds and more efficient manufacturing processes, reinforcing their role in safeguarding critical infrastructure.

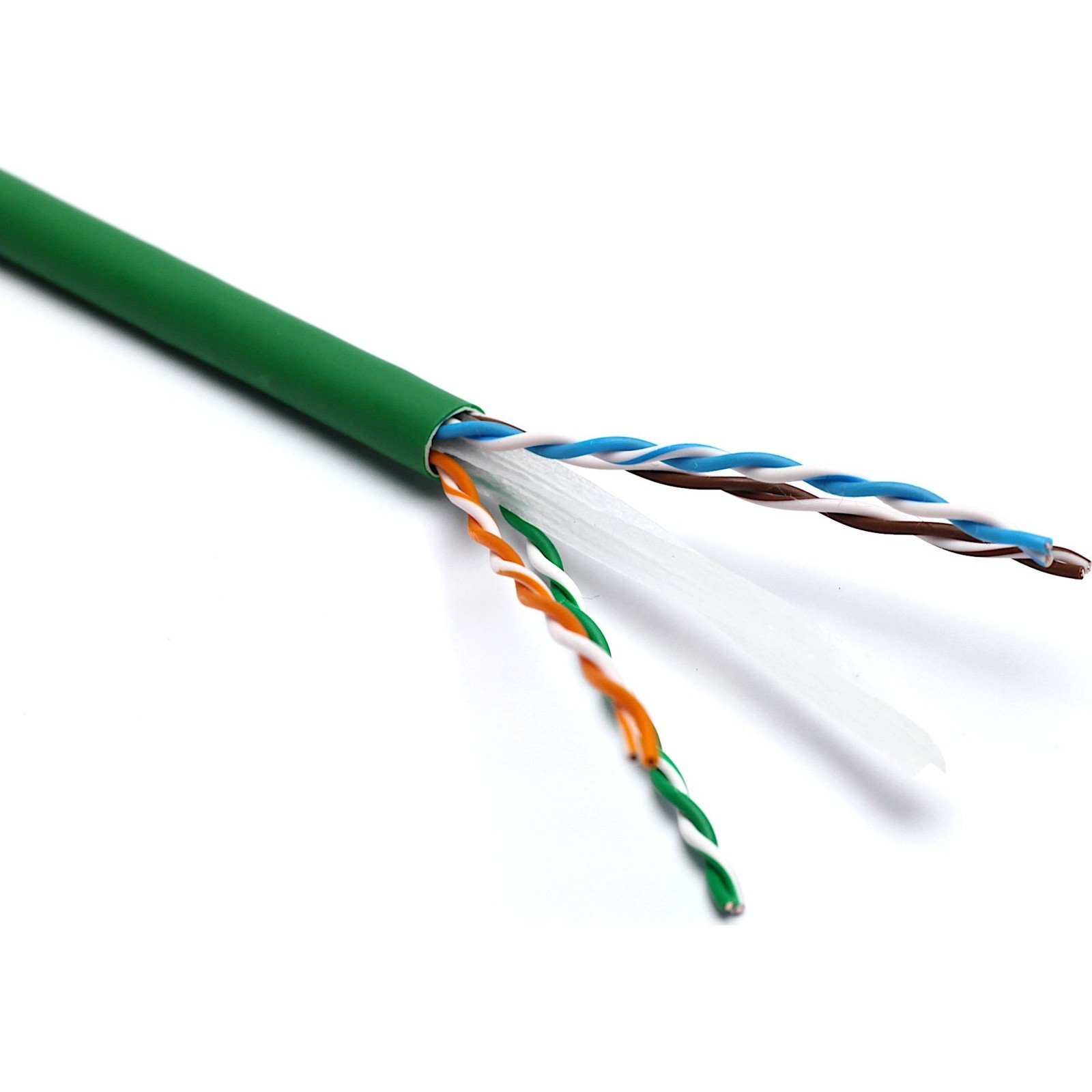

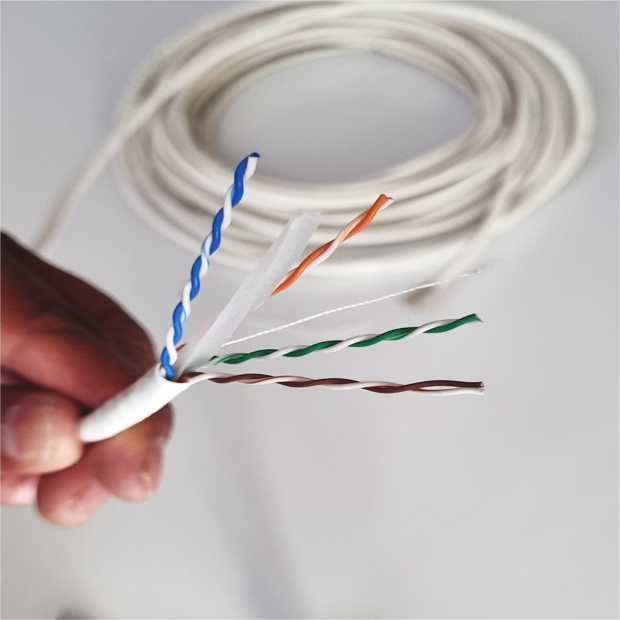

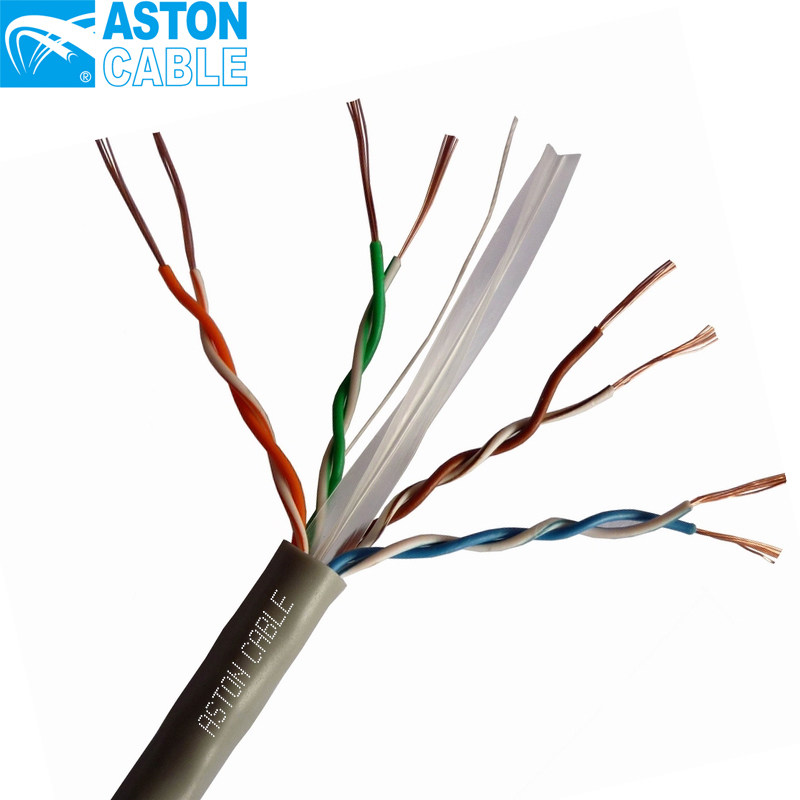

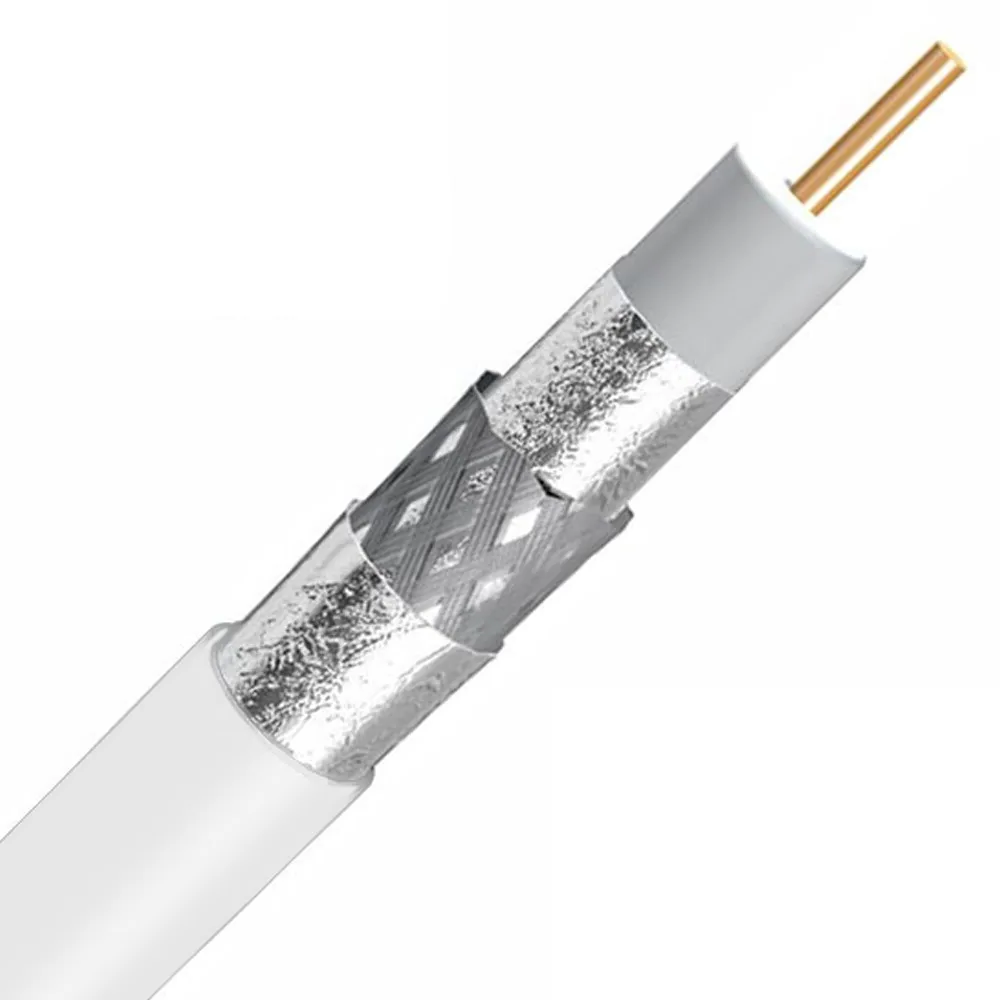

Image Description