Product Main Parameters

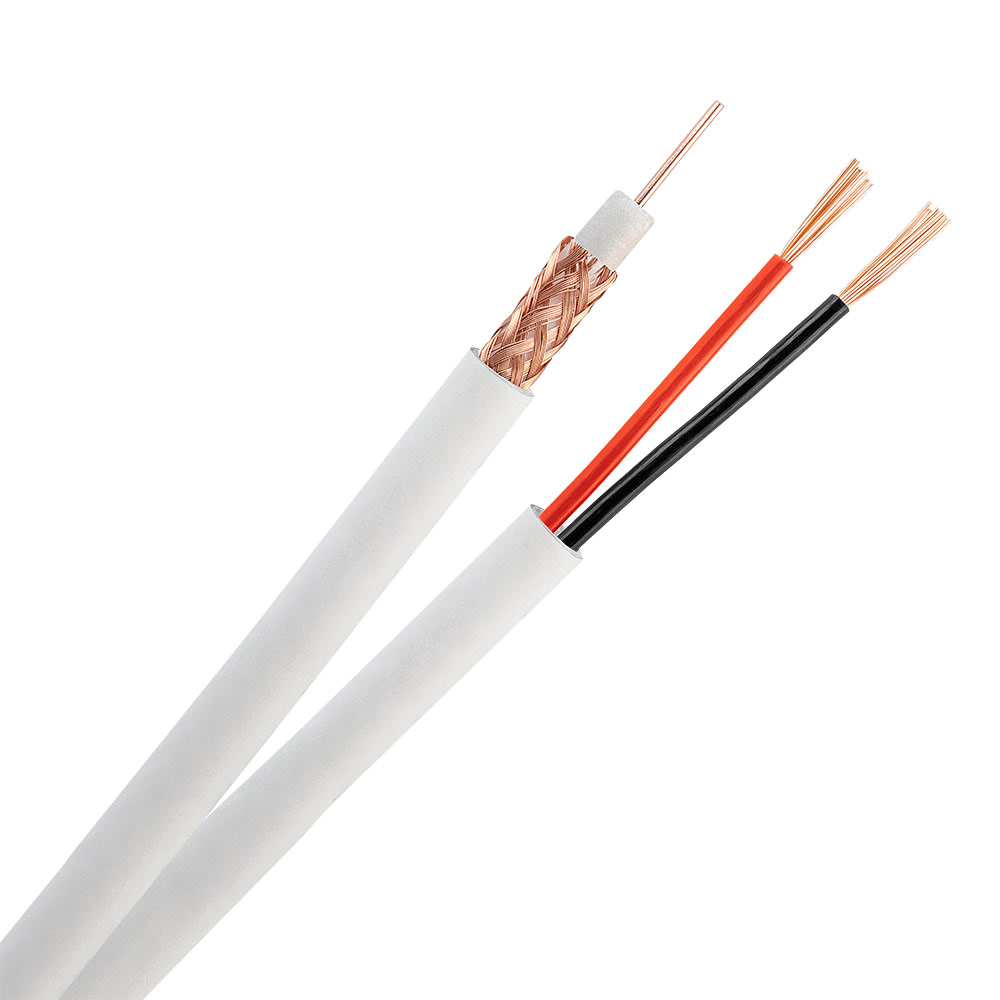

| Conductor | 18 AWG Copper |

| Insulation | Gas Injected Polyethylene |

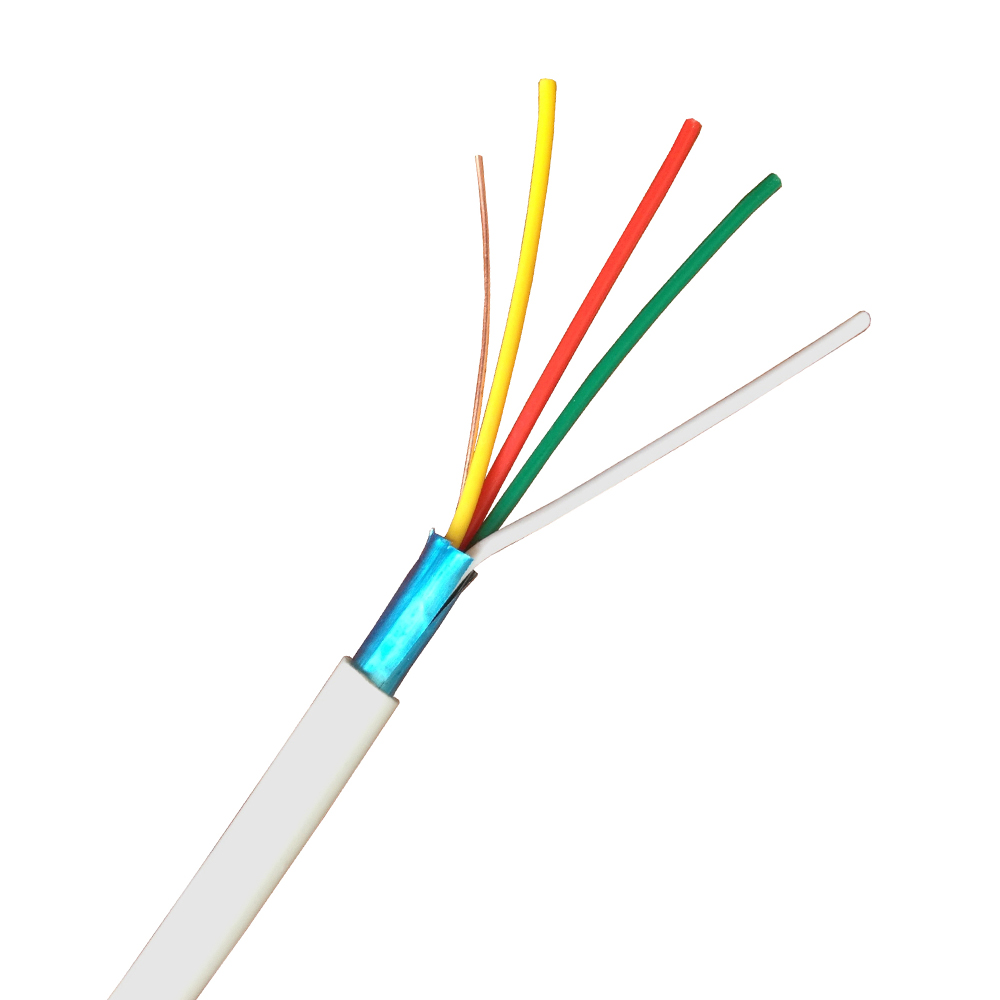

| Jacket Material | PVC |

| Color | White, Black, or Customized |

| Nominal Diameter | 0.265'' |

Common Product Specifications

| Conductor Stranding | Solid |

| Insulation Thickness | 0.180'' Nominal |

| Center Conductor Shield | 100% Al Foil 61% CCA |

| Cable Weight | 35 lbs/1000 ft Nominal |

Product Manufacturing Process

The manufacturing process of copper power cables involves several stages, including drawing, annealing, stranding, insulation, and sheathing. The conductors are first drawn from copper rods to the required diameter and annealed to enhance their flexibility. Stranding follows, where multiple wires are twisted together to improve flexibility and conductivity. Insulation is applied using materials such as PVC or polyethylene to protect against environmental factors. Finally, the cables are sheathed for additional protection. Studies suggest that this meticulous process results in cables with high conductivity, thermal stability, and mechanical strength, making them ideal for various applications.

Product Application Scenarios

Copper power cables are versatile and used across various sectors. In residential settings, they are essential for wiring homes and providing electricity for lighting and appliances. Commercially, these cables form the backbone of electrical infrastructure in office buildings and retail spaces. Industrial applications see copper cables powering heavy machinery and high-voltage systems. The energy sector also relies on copper cables for power generation and transmission over long distances. Research shows that their superior conductivity and durability make them a preferred choice for reliable power supply across these diverse scenarios.

Product After-Sales Service

ASTON Cable provides comprehensive after-sales support including technical assistance, product replacements, and extended warranties. Customer satisfaction is our priority.

Product Transportation

Our copper power cables are packaged for secure transportation; shipped from Ningbo port with tracking services for timely delivery to your location.

Product Advantages

- Superior conductivity and durability

- Excellent thermal performance

- Suitable for diverse applications

- Recyclable material

Product FAQ

- What makes copper power cables more efficient?

Copper's high electrical conductivity minimizes energy loss, ensuring efficient power transmission across various applications, particularly where conservation is critical. - Are copper cables suitable for high-temperature environments?

Yes, copper's thermal stability allows it to withstand higher temperatures, making it ideal for high-power applications without degradation. - Can copper power cables be recycled?

Yes, copper is a fully recyclable material, retaining its properties for reuse, which contributes to environmental sustainability. - What are common applications for copper power cables?

They are used in residential wiring, commercial infrastructure, industrial machinery, and energy sector power transmission due to their reliability and performance. - How do copper cables compare with aluminum cables?

While aluminum is lighter and cheaper, copper offers superior conductivity, thermal performance, and durability, often outweighing aluminum's cost benefits. - Is copper better than other materials for power cables?

Due to its conductivity, heat resistance, and strength, copper remains unmatched in many electrical applications, despite alternatives. - How do copper cables handle environmental factors?

With robust insulation, copper cables resist moisture and temperature fluctuations, ensuring safety and longevity in various settings. - What types of insulation are used for copper power cables?

Common insulations include PVC, XLPE, and EPR, each offering specific benefits in terms of safety and performance for copper cables. - What is the typical lifespan of copper power cables?

Due to their mechanical strength and durability, copper cables have a long service life, often exceeding several decades with proper installation. - How are copper cables protected during installation?

Proper handling and protective armoring can enhance resistance to physical stress, minimizing the risk of damage during and after installation.

Product Hot Topics

- China's Role in Copper Cable Manufacturing

China is a leading player in the global copper cable market, producing high-quality cables that are exported worldwide. The country's advanced manufacturing capabilities and cost-efficient production processes make it a significant contributor to the industry. As demand for reliable energy transmission solutions grows, China's focus on innovation and quality assurance positions it favorably in the marketplace. - Copper Cable Innovations in China

The evolving technological landscape in China has led to numerous advancements in copper cable designs, targeting improved conductivity and reduced environmental impact. Enhanced insulation materials and processes have been developed to optimize performance in various conditions. Continuous research and development ensure that Chinese manufacturers remain at the forefront of cable technology innovation, addressing both domestic and international needs.

Image Description