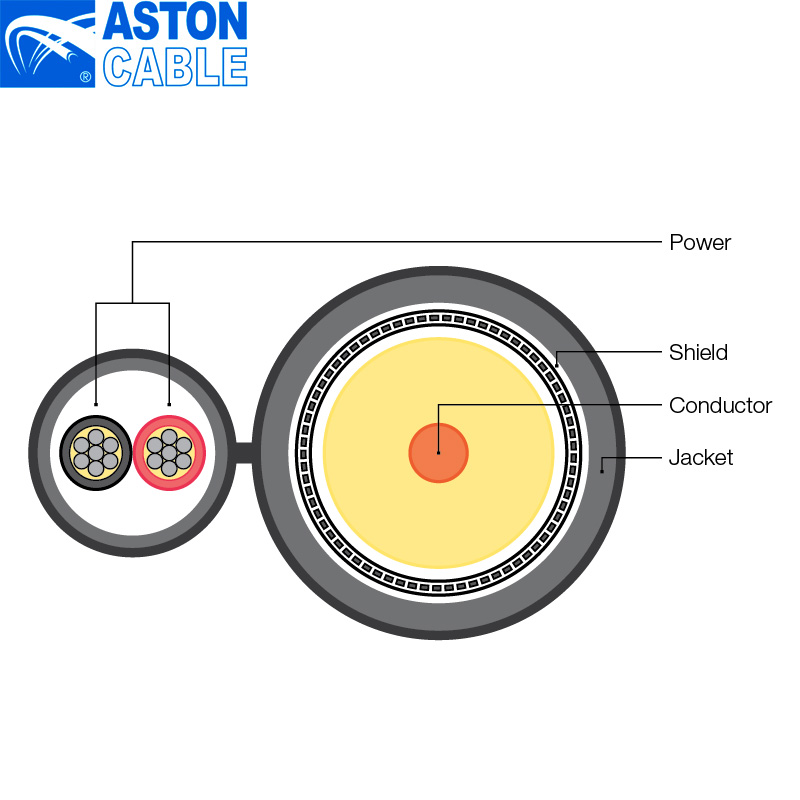

Product Main Parameters

| Parameter | Specification |

|---|---|

| Conductor Material | Copper Clad Aluminum |

| Wire Gauge | 18AWG |

| Shield Coverage | 95% |

| Dielectric | 4.6FPE |

| Daily Output | 200KM |

Common Product Specifications

| Specification | Details |

|---|---|

| Jacket Material | PVC, LSZH, PE |

| Color | Customized |

| Connector | BNCDC |

| Package | Coil reel, plastic drum |

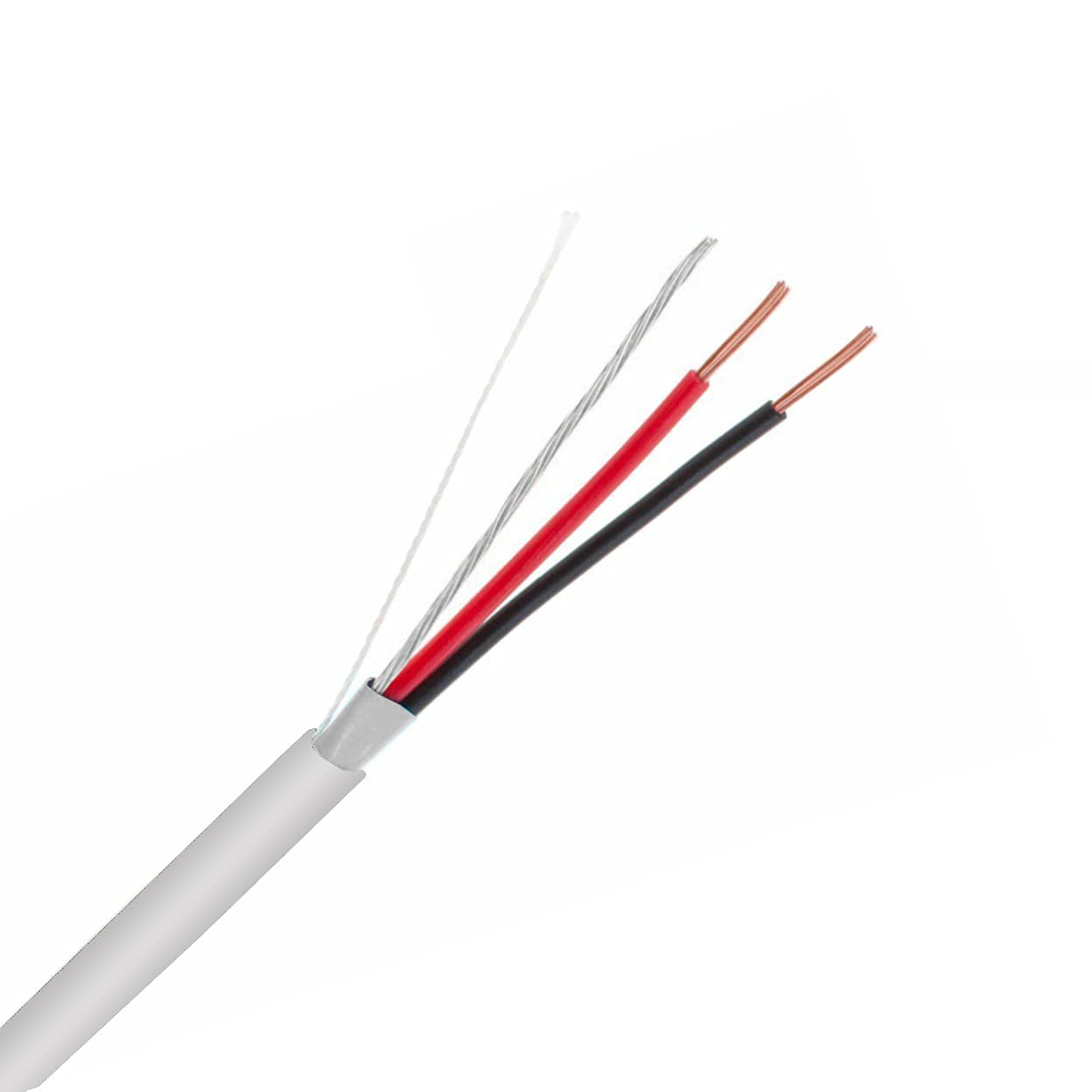

Product Manufacturing Process

The manufacturing process of copper clad aluminum (CCA) wire involves multiple stages, beginning with the selection of high-quality aluminum rods which are then coated with a thin layer of copper through electroplating or cladding processes. This composite wire is then drawn through a series of dies to achieve the desired diameter, ensuring consistent quality and electrical properties. Studies indicate that the CCA wire manufacturing process must maintain precise control over temperature and tension to optimize the mechanical bonding between copper and aluminum layers, enhancing durability and conductivity.

Product Application Scenarios

CCA wires are widely used in telecommunications, electrical transmission, and automotive industries due to their lightweight and cost-effective nature. Research highlights their application in urban infrastructure projects where weight reduction without sacrificing performance is critical. Furthermore, CCA wires are preferred in environments where copper theft is a concern, as their reduced copper content lowers the risk of theft while maintaining adequate conductivity for efficient electrical signal transmission.

Product After-Sales Service

We offer comprehensive after-sales support, including technical assistance, troubleshooting, and warranty services. Our team is dedicated to ensuring customer satisfaction and resolving any issues promptly.

Product Transportation

Products are shipped from our Ningbo port, with standard export packaging to ensure safe transit. We work with reliable logistics partners to facilitate timely and secure delivery to various destinations.

Product Advantages

- Cost-effective alternative to pure copper wires.

- Lightweight yet durable construction.

- Good electrical conductivity suitable for various applications.

- Reduced risk of theft due to lower copper content.

Product FAQ

- What are the main advantages of using CCA wire?

CCA wire combines the conductivity of copper with the cost-effectiveness and lightweight properties of aluminum, making it ideal for applications where weight and price are concerns. - How does the price compare with pure copper wire?

The copper clad aluminum wire price is generally lower than that of pure copper wire, providing an economical choice for many industries without significant loss in conductivity. - Is CCA wire compliant with industry standards?

Yes, our CCA wires comply with RoHS, CE, and IEC standards, ensuring high-quality and safe use in various applications. - Can CCA wire be used in high-frequency applications?

Yes, CCA wire can efficiently transmit signals at high frequencies, suitable for broadband and satellite communications. - What customization options are available for CCA wire?

We offer various jacket materials, colors, and connectors to meet specific customer needs and application requirements.

Product Hot Topics

- Trends in Copper Clad Aluminum Wire Pricing

Understanding the market dynamics affecting copper clad aluminum wire price is crucial for buyers. With fluctuating raw material costs and changing demand in sectors like telecommunications and automotive, staying informed through market reports and supplier quotes is important. - The Role of CCA Wire in Modern Telecommunications

CCA wire is playing an increasingly crucial role in modern telecommunications due to its excellent balance between performance and cost. With ongoing advancements, manufacturers are innovating to enhance the properties of CCA wire, thus meeting the growing demands of high-speed data transmission.

Image Description