Product Details

| Place of Origin | China |

|---|---|

| Brand Name | ASTON or OEM |

| Certification | SGS CE ROHS ISO9001 |

| Daily Output | 200KM |

Common Product Specifications

| Wire Sizes | 0.12mm-3.0mm |

|---|---|

| Color | Copper color |

| Packages | Plastic drum |

| Usage | Cable conductor |

| Logo | OEM |

| Industrial Use | Conductor or braiding |

Product Manufacturing Process

The manufacturing process of copper clad wires involves an intricate technique known as cladding, where a core of aluminum is bonded with a layer of copper. According to authoritative research, this method enhances conductivity while optimizing cost efficiency. The process includes multiple quality checks to ensure uniformity in conductivity and durability, making it ideal for varied applications. The approach is not only economically beneficial but also aligns with modern regulatory standards regarding material use and sustainability.

Product Application Scenarios

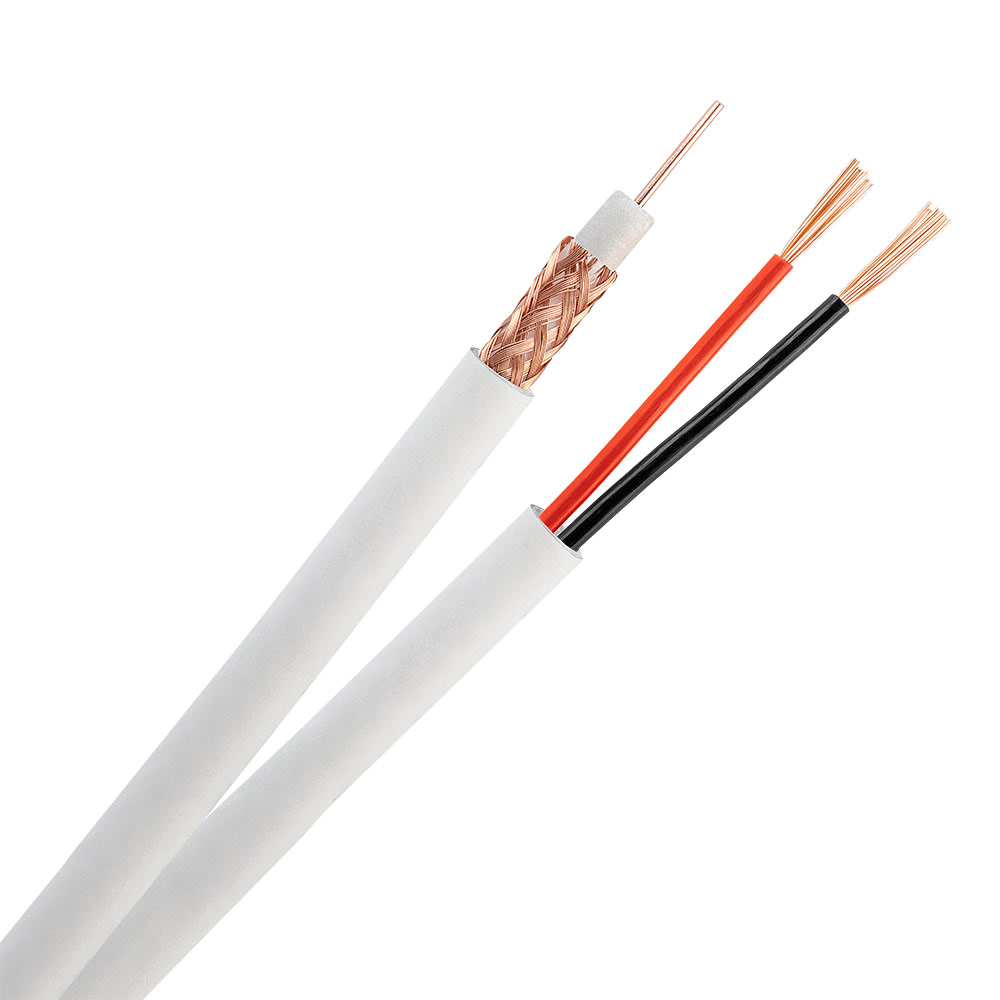

Copper clad aluminum wires are extensively used in diverse fields due to their unique properties. As highlighted in industry papers, these wires are crucial in telecommunications for LAN cables and coaxial cable applications. They also find use in power transmission as control cables and stranded wires due to their balance of conductivity and weight savings. The automotive sector utilizes them in wiring as a cost-effective alternative to pure copper. Their adaptability extends to specialized electromagnetic environments, offering reliable performance in devices like motors and loudspeakers.

Product After-sales Service

Our company commits to providing comprehensive after-sales service including technical support, warranty services, and customer feedback mechanisms to ensure satisfaction.

Product Transportation

Products are packaged for export using standard materials in compliance with international shipping regulations. The port of delivery is Ningbo, ensuring efficient logistical operations.

Product Advantages

- Cost-effective compared to pure copper

- High conductivity for diverse applications

- Durable and reliable

- Environmentally friendly with sustainable manufacturing practices

Product FAQ

- What is the price of copper clad wire from this manufacturer?

The price can vary based on market conditions and order quantity. Contact us directly for a quote.

- What core materials are used in the manufacturing?

Our copper clad wires predominantly feature an aluminum core, ensuring a blend of conductivity and cost-effectiveness.

- Are your products environmentally compliant?

Yes, our manufacturing processes align with ISO14001 standards and our products are RoHS compliant.

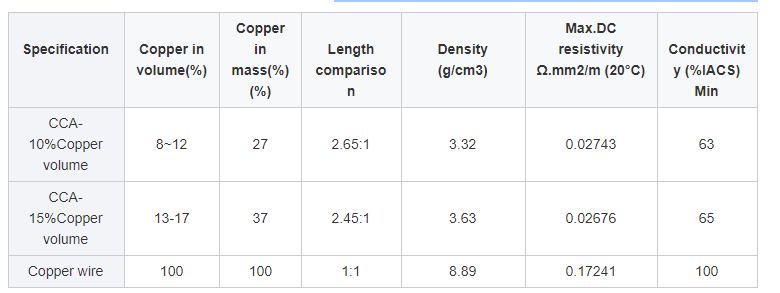

- How does CCA wire performance compare to pure copper?

While slightly lower in conductivity, CCA wire offers significant cost savings and suitable electric performance for many applications.

- Can I order custom sizes?

Yes, we offer customization on wire sizes from 0.12mm to 3.0mm based on customer requirements.

- What is the minimum order quantity?

The MOQ is 30 km for specialized orders, but standard requirements may be subject to other conditions.

- Is your packaging export compliant?

Our packaging solutions are designed for international compliance, safeguarding the product during transit.

- Do you offer technical support post-sale?

Yes, we provide comprehensive technical support and assistance to ensure optimal product performance.

- What sectors typically utilize these wires?

Our CCA wires are utilized in telecommunications, automotive, power transmission, and specialized electronics industries.

- How can I stay updated on copper clad wire prices?

Regular updates are available through our market reports and direct communication channels with our sales team.

Product Hot Topics

- Industry Trends in Copper Clad Wire Price

The dynamics of copper clad wire price are shaped by market demand, geopolitical influences, and raw material costs. Manufacturers often face challenges balancing competitive pricing with sustainable practices. Staying informed on these trends can assist in strategic procurement and investment decisions.

- The Role of Manufacturers in Ensuring Quality

Manufacturers play a pivotal role in determining the quality of copper clad wires. By adhering to strict quality control measures and leveraging advanced production technologies, leading manufacturers ensure that their products meet industry standards, fostering trust and reliability among customers.

- Comparative Analysis: Copper Clad vs. Pure Copper

While pure copper remains the benchmark for conductivity, copper clad solutions offer a budget-friendly alternative with adequate performance. The choice between the two often depends on specific application needs and cost considerations, with copper clad wires taking the lead in high-volume, cost-sensitive scenarios.

- Sustainable Manufacturing Practices

As environmental concerns rise, manufacturers are increasingly prioritizing sustainable practices in the production of copper clad wires. This involves optimizing resource use, minimizing waste, and ensuring compliance with environmental regulations, thus contributing to a greener industry footprint.

- The Future of CCA Wires in Telecommunications

The expansion of digital infrastructure globally has bolstered the demand for CCA wires, especially in telecommunications. These wires offer a reliable and cost-effective solution for expanding cable networks, enabling broader accessibility and connectivity.

- Technological Innovations in Wire Cladding

Advancements in cladding technologies have revolutionized the production of copper clad wires. These innovations ensure better bonding, higher conductivity, and greater durability, enhancing the performance and longevity of the wires in various applications.

- The Impact of Geopolitical Events on Copper Clad Wire Prices

Geopolitical tensions and trade policies significantly influence the pricing of raw materials like copper and aluminum. Understanding these dynamics helps manufacturers and consumers anticipate shifts in the market, allowing for strategic planning and agility in procurement practices.

- Customization and Flexibility in Wire Manufacturing

Customized solutions are becoming a hallmark of leading copper clad wire manufacturers, offering flexibility in design and specifications to meet diverse consumer needs. This trend facilitates innovation and application-specific developments in the industry.

- Challenges in Supply Chain Management

Supply chain disruptions pose significant challenges to manufacturers, impacting the availability and price of copper clad wire. Effective management strategies and diversification of sources are crucial in mitigating these risks, ensuring consistent supply and pricing stability.

- The Growing Market for Lightweight Automotive Wiring

The automotive industry’s shift towards lightweight materials has increased the demand for copper clad wires. These wires not only reduce weight but also maintain necessary performance levels, making them ideal for modern vehicle designs prioritizing efficiency and sustainability.

Image Description