Product Main Parameters

| Parameter | Details |

|---|---|

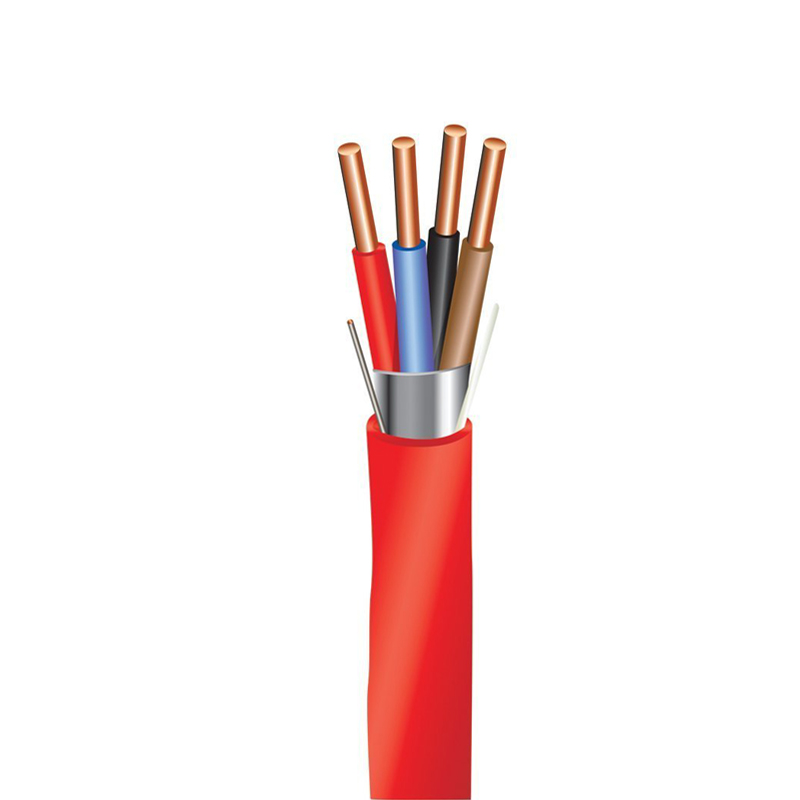

| Conductors | Fine strands of plain copper |

| Insulation | PVC or similar material |

| Bedding | PVC |

| Braided Shield | Tinned copper |

| Outer Sheath | PVC or LSZH |

Common Product Specifications

| Specification | Details |

|---|---|

| Core | 4 Pair stranded conductor |

| Insulation Material | HDPE |

| Flame Retardant | IEC compliant |

| Shielding | None |

| Origin | Hangzhou, Zhejiang |

Product Manufacturing Process

Manufacturing CY control cables involves precise processes to ensure durability and reliability. According to industry research, the process starts with selecting high-grade copper for the conductors, which are then stranded to enhance flexibility and resilience. The conductors are insulated with PVC to prevent short-circuiting. A bedding layer follows to secure the conductors, after which a braided shield of tinned copper is applied to protect against EMI. The final outer sheath, crafted from PVC or LSZH, ensures the cable is resistant to physical and chemical damages. This meticulous process is crucial for producing high-performance industrial cables.

Product Application Scenarios

CY control cables are essential in industries requiring precise control and data transmission. An authoritative paper highlights their utility in automation, where they connect sensors and controllers, critical in minimizing interference. In manufacturing, these cables maintain production line efficiency by safely transmitting control signals. Building management systems also rely on CY cables for seamless integration of lighting, HVAC, and critical infrastructure. Broadcasting environments benefit from CY cables by ensuring clear audio and video transmission, vital in media production.

Product After-sales Service

Our company provides comprehensive after-sales support, including technical assistance, installation guidance, and warranty services to ensure satisfaction with our CY control cables.

Product Transportation

We ensure timely and secure delivery through trusted logistics partners, guaranteeing that your CY control cable products reach you in pristine condition.

Product Advantages

- EMI Protection

- Flexibility

- Durability

- Versatility

Product FAQ

- What is the primary use of CY control cables?

CY control cables are predominantly used for data transmission in industrial automation, connecting sensors, and control units to reduce electromagnetic interference.

- Can CY control cables be used outdoors?

While CY control cables are primarily designed for indoor applications, they can be used outdoors with appropriate protective enclosures to shield against environmental factors.

- What materials are used in CY control cables?

The primary materials include stranded copper conductors, PVC insulation, a braided tinned copper shield, and a PVC or LSZH outer sheath.

- Are CY control cables flexible?

Yes, CY control cables are designed with stranded conductors and flexible outer sheaths, making them easy to install in tight spaces and dynamic environments.

- What are the fire safety features of CY control cables?

CY control cables with LSZH sheaths produce minimal smoke and toxic gases during a fire, enhancing safety in enclosed areas.

- Do CY control cables offer EMC protection?

Yes, the braided copper shield in CY control cables effectively reduces electromagnetic interference, ensuring clear data transmission.

- How is CY control cable durability ensured?

Durability is ensured through high-quality materials like copper and robust design that withstands mechanical and environmental stresses.

- What standards do CY control cables comply with?

Our CY control cables comply with CE, RoHS, and IEC standards, ensuring they meet international safety and performance benchmarks.

- Can CY control cables be customized?

Yes, we offer customization options for length, color, and material to meet specific customer requirements and applications.

- How does CY control cable fare in industrial uses?

In industrial settings, the CY control cable excels in ensuring reliable data transmission and power distribution amidst challenging environmental conditions.

Product Hot Topics

- The Evolution of CY Control Cable Technology

The continuous advancement in CY control cable technology demonstrates the importance of innovation in meeting industrial demands. As a leading manufacturer, we've adapted by integrating materials like tinned copper to enhance EMI protection. These innovations stem from rigorous R&D efforts, informed by industry studies and customer feedback, ensuring our cables meet the evolving needs of modern applications without compromising on performance or safety.

- Understanding CY Control Cable Applications

CY control cables serve a vital role in various industrial applications. As a top manufacturer, our cables are engineered to deliver precision in data transmission, a need that has grown with increased automation and smart systems. The reliability and durability of these cables make them indispensable in environments like manufacturing, broadcasting, and building management, emphasizing the need for high-quality, interference-resistant cabling solutions.

- Why Flexibility Matters in CY Control Cables

Flexibility in CY control cables is crucial for navigating complex installations. Our role as a leading manufacturer emphasizes producing cables with stranded conductors, ensuring easy adaptability. This flexibility minimizes installation issues and allows for efficient layout adjustments, proving vital in fast-paced, ever-changing industrial environments. Meeting these challenges head-on, our cables support dynamic operations without compromising on performance.

- The Future of CY Control Cables in Smart Industries

As industries evolve towards smarter, automated systems, the demand for reliable CY control cables increases. As a manufacturer at the forefront, we are dedicated to developing cables that meet these needs, providing enhanced EMI protection and durability. Ensuring seamless integration with emerging technologies, our cables are ready to support future industrial advancements.

- How CY Control Cables Ensure Data Integrity

CY control cables are engineered to maintain data integrity even in high-interference environments. Our manufacturing expertise focuses on leveraging tinned copper shielding to combat electromagnetic interference. This capability ensures our cables deliver clear, accurate data signal transmissions, a necessity in critical applications such as broadcasting and industrial automation.

- The Role of LSZH in CY Control Cables

LSZH (Low Smoke Zero Halogen) materials enhance the safety profile of CY control cables. As a responsible manufacturer, we prioritize incorporating LSZH sheaths to reduce smoke and toxic gas emissions during fires. This initiative highlights our commitment to safety, particularly in enclosed or densely populated installations where fire safety is paramount.

- Meeting Industrial Standards with CY Control Cables

Compliance with international safety and performance standards is non-negotiable in CY control cable manufacturing. Our products adhere to CE, RoHS, and IEC standards, reflecting our commitment to quality and safety. These certifications assure customers of the cables' reliability in demanding environments, emphasizing our role as a trusted manufacturer ensuring optimal performance under all conditions.

- Customizing CY Control Cables for Specific Needs

Customization is a key service in CY control cable production, allowing adaptation to specific application requirements. As a leading manufacturer, we offer tailored solutions in cable length, color, and material to align with customer needs. This flexibility ensures that our cables can seamlessly integrate into diverse setups, maintaining performance while meeting detailed specifications.

- The Importance of Durability in CY Control Cables

Durability is essential for CY control cables operating in harsh industrial conditions. Our manufacturing processes prioritize high-grade materials and robust construction, resulting in products that withstand mechanical and environmental stress. This focus on longevity aligns with our commitment to providing reliable solutions for demanding applications.

- Advances in EMI Protection for CY Control Cables

In an age of increasing electronic interference, CY control cables with advanced EMI protection are indispensable. As a leading manufacturer, we've invested in refining our cables' shielding components, using tinned copper braiding to ensure clear signal transmission. These advancements reflect our dedication to delivering cables that meet contemporary challenges and maintain performance in complex environments.

Image Description