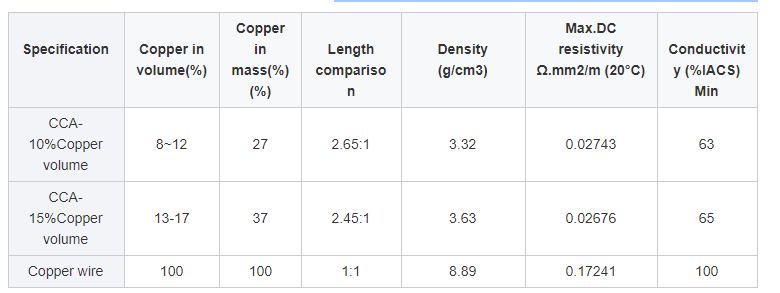

Product Main Parameters

| Parameter | Details |

|---|---|

| Material | Copper Clad Aluminum |

| Sizes | 0.12mm-3.0mm |

| Color | Copper color |

| Usage | Cable Conductor |

Common Product Specifications

| Specification | Details |

|---|---|

| Daily Output | 200KM |

| Annual Supply | 25000KM/Per year |

| MOQ | 30km |

Product Manufacturing Process

The manufacturing of copper clad aluminum cable at our factory involves an intricate process of metallurgical bonding. An aluminum core, either solid or stranded, is encapsulated with a thin layer of copper through methods such as cladding, electroplating, or co-extrusion. This bonding ensures optimal contact between the two metals, achieving efficient conductivity while maintaining the lightweight and economical advantages of aluminum. The selection of the manufacturing method depends largely on the desired application and characteristics required by the end product. The process is governed by high standards of quality control, adhering to international certifications such as ISO9001 to ensure the final product meets the rigorous demands of various industry standards.

Product Application Scenarios

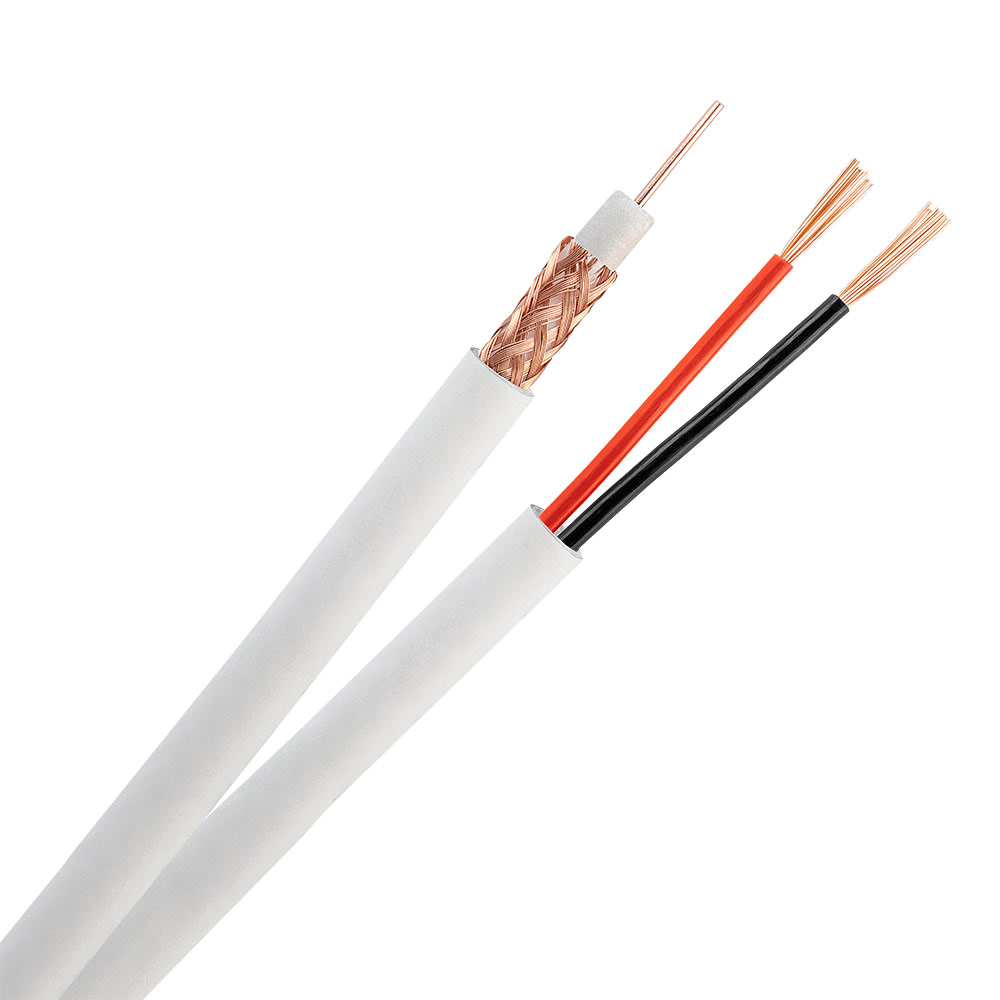

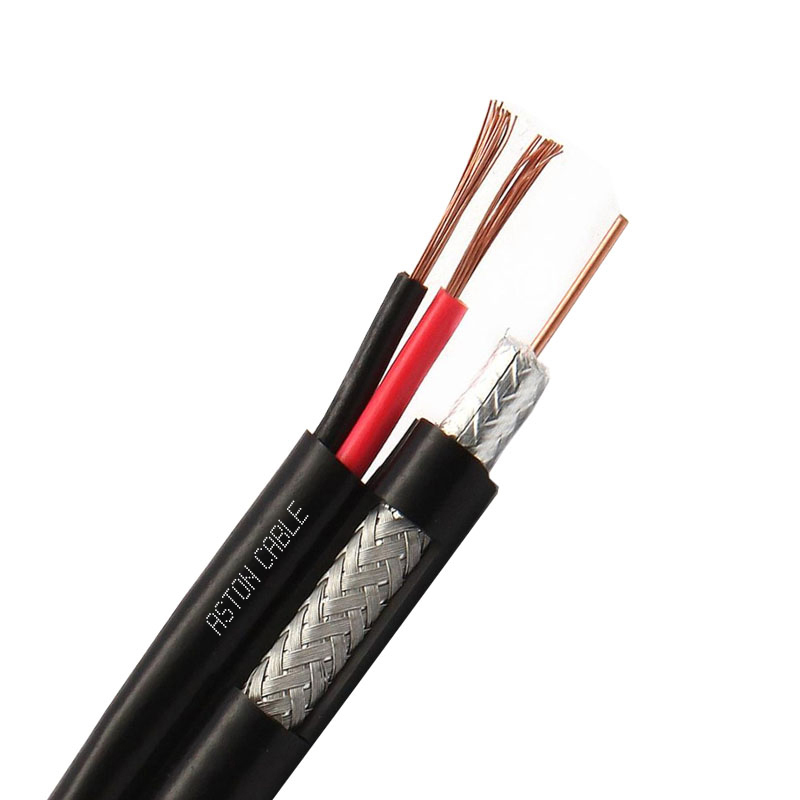

Copper clad aluminum cables produced by Aston Cable factory serve a wide array of application scenarios. In telecommunications, they are pivotal in coaxial cables for TV and internet setups, offering cost-benefit without much compromise on performance. Their lightweight and conductivity make them suitable for short-run Ethernet cables in network installations. Additionally, the automotive sector utilizes these cables to reduce vehicle weight, thereby enhancing fuel efficiency. They are also employed in low to medium power distribution tasks, particularly where cost and weight are critical considerations. While these cables are versatile and economical, they must be chosen with an understanding of their limitations in high-power or mechanically demanding applications.

Product After-Sales Service

At Aston Cable factory, we are dedicated to customer satisfaction with comprehensive after-sales service. Our team is available to address any concerns and provide guidance on the optimal use of our copper clad aluminum cables. We offer warranty services, technical support for installation, and assistance for any returns or exchanges. Our priority is to ensure that our customers are thoroughly satisfied with both the product and service they receive.

Product Transportation

We ensure that our copper clad aluminum cables are securely packaged for transportation, minimizing any risk of damage. Packaging typically involves robust plastic drums that safeguard the integrity of the cables. Shipping is facilitated through various logistics partners, with options tailored to meet the urgency and budgetary constraints of our customers. We manage the entire process from our factory to the designated delivery port, ensuring timely and efficient transport.

Product Advantages

- Cost-Effective: Significantly reduces costs by using aluminum core without sacrificing much conductivity.

- Lightweight: Easier installation and handling due to reduced weight compared to pure copper cables.

- Conductivity: Maintains good conductivity through copper cladding.

- Corrosion Resistance: Copper layer protects the aluminum core, enhancing lifespan.

- Flexibility: More flexible than solid copper, suited for applications requiring frequent movement.

Product FAQ

What is the lifespan of copper clad aluminum cables?

The lifespan of copper clad aluminum cables from our factory varies based on environmental conditions and application usage. However, with proper installation and care, they can last many years.Are these cables suitable for outdoor use?

While copper clad aluminum cables can be used indoors and in protected outdoor environments, additional insulation may be required for harsh outdoor conditions to preserve performance.How does the conductivity of CCA compare to pure copper?

While slightly less conductive than pure copper, our copper clad aluminum cables maintain efficiency adequate for many telecommunications and data transmission needs.What installation considerations should be taken?

Ensure proper gauge selection based on application and adhere to installation guidelines to ensure optimal performance of the copper clad aluminum cable.What are the standard packaging options?

Our factory offers standard export packaging in plastic drums, designed to protect against damage during transportation.Can the cables be customized?

Yes, we can customize cable lengths and specifications according to customer requirements from our factory.What certifications do these cables have?

Our copper clad aluminum cables meet SGS, CE, ROHS, and ISO9001 standards, ensuring they adhere to international quality benchmarks.What is the typical delivery time?

Delivery times vary based on order size and destination, but we strive to provide timely dispatch from our factory.Are there compatibility issues with existing systems?

While generally compatible, it's important to consult with our technical team if upgrading from pure copper cables to copper clad aluminum versions to ensure compatibility.What support does Aston Cable offer after purchase?

Our factory provides comprehensive support, including installation guidance, warranty services, and a dedicated customer service team to address post-purchase inquiries.

Product Hot Topics

How does copper clad aluminum cable benefit developing regions?

At Aston Cable factory, we understand the need for affordable yet effective solutions in developing regions. Copper clad aluminum cables play a pivotal role by providing a cost-effective alternative to pure copper cables, thus extending networking and power solutions to areas with budget constraints. By combining the conductivity of copper and the affordability of aluminum, these cables help bridge the connectivity gap, bringing essential telecommunications and power infrastructure to underdeveloped areas. They enable communities to access reliable cable solutions without compromising on performance significantly, facilitating growth and development.

Why is weight an important factor in cable selection?

The weight of a cable, as emphasized by Aston Cable factory, impacts handling and installation costs, especially in complex infrastructure projects. Copper clad aluminum cables are notably lighter than solid copper, making them easier to transport and install, particularly in large-scale operations. This weight advantage translates into reduced labor and logistical costs. For applications requiring extensive cable runs or installations in difficult-to-access areas, the lightweight nature of these cables offers substantial benefits, enhancing the overall efficiency and cost-effectiveness of projects.

Image Description