Product Details

| Product Name | LAN CABLE CAT5E |

|---|---|

| Jackets | PVC, LSZH, PE |

| Color | Customized |

| Conductor | 24AWG Bare Copper |

| Logo | OEM |

| Industrial Use | Network Data |

| Origin | Hangzhou, Zhejiang |

Common Product Specifications

| Conductor | Bare Copper Solid or Stranded Flexible section in 24AWG |

| Core | 4Pair stranded conductor |

| Insulation | 0.98 HDPE Retardant meet the requirement of IEC |

| Shielding | Al foil |

| Outer Jacket | PVC, PE or LSZH |

Product Manufacturing Process

The manufacturing process of our factory network cable Cat 5 follows stringent quality control procedures to ensure high performance and durability. The process begins with the selection of high-quality raw materials, including 24AWG bare copper for the conductors. These conductors are then twisted into pairs at specific rates to minimize crosstalk and electromagnetic interference (EMI). The twisted pairs are insulated with high-density polyethylene (HDPE) and then shielded with aluminum foil to provide additional protection against external interference. Finally, the cables are jacketed with either PVC, PE, or LSZH material, depending on specific customer requirements. Advanced machinery and rigorous testing ensure that every cable meets international standards and delivers superior performance in real-world applications.

Product Application Scenarios

Our factory network cable Cat 5 is versatile and suitable for various applications. It is commonly used in Ethernet networks to connect computers, servers, switches, and routers in local area networks (LANs). Additionally, it is used in telephony to transmit voice signals efficiently. The cable is also integrated into security camera systems, providing both power and data transmission capabilities. Its robust construction and high data transmission rates make it ideal for small offices and home environments, where networks require reliable performance without exceeding gigabit speeds. The cable's shielding and robust construction ensure minimal interference, making it a reliable choice for various industrial and residential uses.

Product After-Sales Service

- 24/7 Customer Support

- Replacement Warranty

- Technical Assistance

- Easy Return Policy

- Online Trouble-Shooting Guides

Product Transportation

- Standard Export Packaging

- Delivery Port: Ningbo

- Supply Ability: 25000KM/Per year

Product Advantages

- High-quality 24AWG bare copper conductors

- Excellent shielding with aluminum foil

- Durable outer jacket options: PVC, PE, LSZH

- Supports up to 1 Gbps data transfer rates

- Ideal for small offices and home networks

Product FAQ

1. What is the maximum data transfer rate of the Cat 5 cable?

Our factory network cable Cat 5 supports data transfer rates up to 1 Gbps, making it suitable for Gigabit Ethernet applications.

2. What materials are used in the construction of this cable?

The cable features 24AWG bare copper conductors, HDPE insulation, aluminum foil shielding, and an outer jacket made of either PVC, PE, or LSZH.

3. What is the recommended length for optimal performance?

The maximum recommended length for the Cat 5 cable is 100 meters, including patch cables and horizontal cabling.

4. Can this cable be used for commercial office networks?

Yes, the cable is ideal for small office networks, offering reliable performance and high data transfer rates.

5. Is this cable compliant with international standards?

Yes, our factory network cable Cat 5 is compliant with international standards such as ISO9001, ISO14001, RoHS, CE, and IEC.

6. Does the cable offer protection against electromagnetic interference?

Yes, the cable features aluminum foil shielding to minimize electromagnetic interference (EMI) and crosstalk.

7. What are the color options for the cable jacket?

The cable jacket is available in various colors, which can be customized according to customer requirements.

8. What is the minimum order quantity?

The minimum order quantity for our factory network cable Cat 5 is 200 rolls, with each roll containing 305 meters of cable.

9. What applications is this cable suitable for?

This cable is suitable for Ethernet networks, telephony, and security systems, providing reliable data transmission and durability.

10. What after-sales services are provided?

We offer 24/7 customer support, a replacement warranty, technical assistance, an easy return policy, and online troubleshooting guides.

Product Hot Topics

1. Why Choose Factory Network Cable Cat 5?

Choosing a factory network cable Cat 5 from Aston Cable provides several advantages. The cable is manufactured using high-quality 24AWG bare copper, ensuring excellent electrical performance and enduring durability. Its aluminum foil shielding offers superior protection against electromagnetic interference (EMI), making it ideal for environments with high levels of external interference. The cable also supports data transfer rates of up to 1 Gbps, which is more than sufficient for most small office and home network applications. Additionally, the cable is compliant with international standards such as ISO9001, ISO14001, RoHS, CE, and IEC, ensuring that you are investing in a high-quality, reliable product.

2. Installation Tips for Factory Network Cable Cat 5

To ensure optimal performance when installing factory network cable Cat 5, several best practices should be followed. First, avoid placing the cables near potential sources of electromagnetic interference, such as fluorescent lights and heavy machinery. This will help to minimize signal distortion. Proper termination is also crucial; using quality connectors and crimping tools will ensure secure connections and reduce the risk of signal loss. Finally, maintain the integrity of the cable by avoiding sharp bends or kinks, as these can damage the twisted pairs and degrade performance. Testing the cables after installation using cable testers can also verify their integrity and performance.

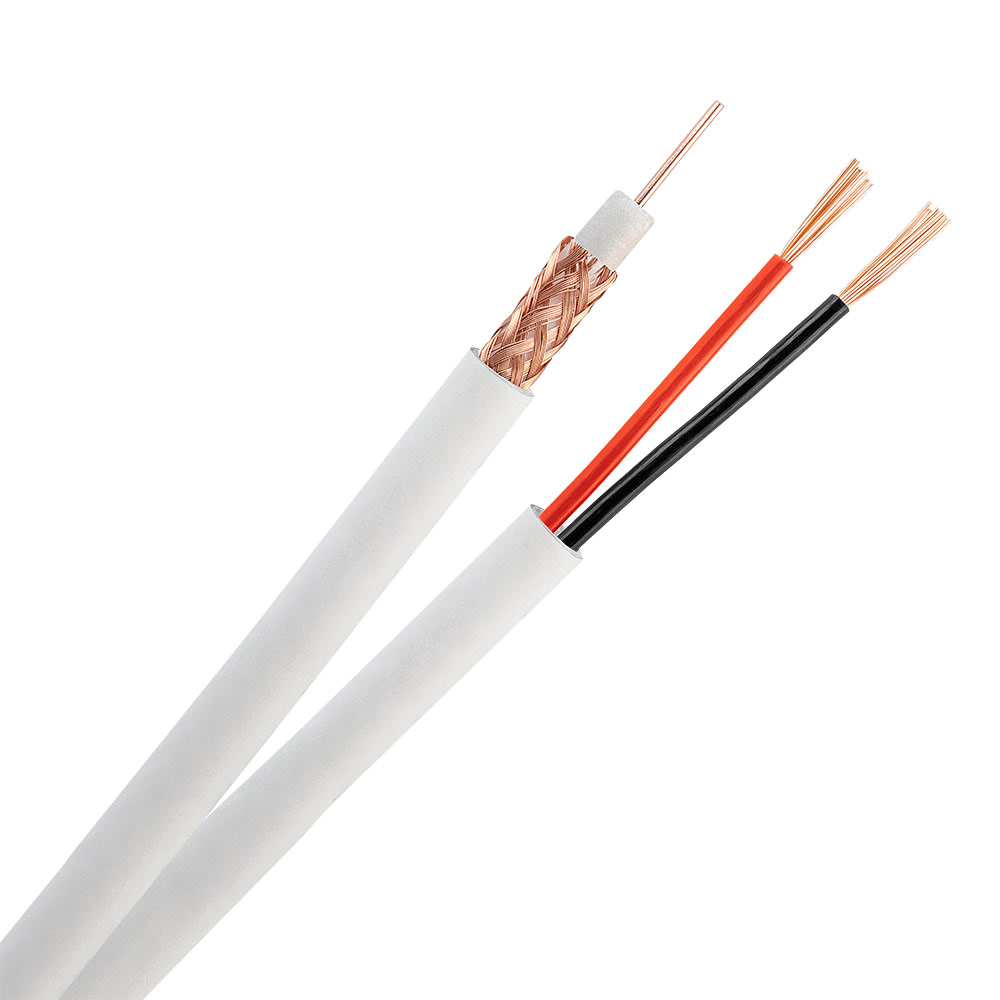

Image Description