Product Main Parameters

| Parameter | Value |

|---|---|

| Diameter | 0.12mm-3.0mm |

| Color | Copper color |

| Core Material | Aluminum |

| Coating | Copper |

Common Product Specifications

| Specification | Details |

|---|---|

| MOQ | 1000KG |

| Daily Output | 200KM |

| Annual Supply | 25000KM |

| Origin | Hangzhou, Zhejiang |

Product Manufacturing Process

CCA copper wire manufacturing involves surrounding an aluminum core with a thin layer of copper through processes such as electroplating or cladding under high pressure and temperature. This technique merges the benefits of both metals, resulting in a product that balances cost, weight, and conductivity. According to industry research, electroplating provides a uniform copper layer, enhancing conductivity, while cladding ensures a robust bond between copper and aluminum. Studies emphasize the importance of controlled environmental conditions to maximize product durability and performance.

Product Application Scenarios

CCA copper wire is widely applied in industries prioritizing weight and cost over absolute conductivity. In telecommunications, it's used for long-distance signal transmission in coaxial cables. The automotive industry benefits from its lightweight property, contributing to fuel efficiency. In building construction, CCA wire is a viable alternative for wiring where moderate conductivity suffices. Research indicates CCA wire's adaptability to various environments, though it's crucial to assess specific requirements such as electrical load and climate conditions to ensure optimal performance.

Product After-Sales Service

Aston Cable factorys provides comprehensive after-sales support including technical assistance, product replacement for any manufacturing defects, and customer service for installation queries.

Product Transportation

The CCA copper wire is transported in secure, normal export packaging to ensure the integrity of the product during transit. Shipping is available through the port of Ningbo with careful handling to minimize damage risk.

Product Advantages

- Cost-effective alternative to copper wire.

- Lightweight, reducing installation effort.

- Acceptable conductivity for various applications.

Product FAQ

- What is the primary benefit of factorys CCA copper wire? The primary benefit of our CCA copper wire is its cost-effectiveness, combining the conductive properties of copper with the lightweight and affordability of aluminum. This makes it an ideal choice for applications where cost and weight are critical considerations.

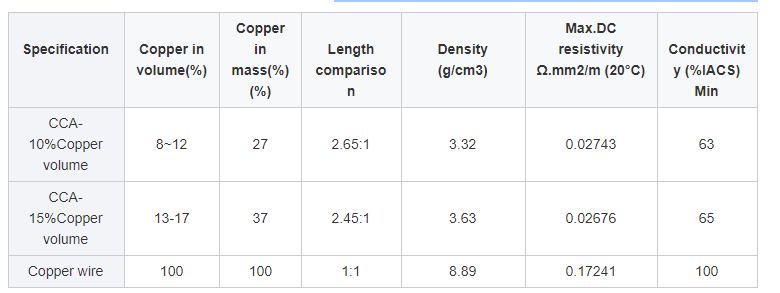

- How does CCA copper wire compare to pure copper wire in terms of conductivity? While CCA copper wire has lower conductivity than pure copper wire, its copper cladding ensures it maintains acceptable levels of conductivity for many applications, making it a cost-effective alternative in scenarios where the highest conductivity is not needed.

- What are the typical applications of factorys CCA copper wire? Factorys CCA copper wire is typically used in telecommunications for coaxial cables, in the automotive industry for wiring to reduce vehicle weight, and in building construction where moderate conductivity is sufficient.

- Is CCA copper wire suitable for outdoor use? CCA copper wire can be used outdoors, but it's important to consider the environmental conditions. Its aluminum core is prone to oxidation, so protective measures should be taken to ensure long-term durability.

- Can the aluminum core of CCA copper wire withstand high temperatures? The aluminum core can withstand temperature variations, but extreme temperatures may impact its performance. It's advisable to check the specific temperature ratings for each application to ensure reliability.

- How does the factorys ensure quality in CCA copper wire production? Our factory employs advanced machinery and rigorous quality control systems, adhering to ISO9001 and ISO14001 standards, to ensure each batch of CCA copper wire meets the highest quality standards.

- What is the lifespan of CCA copper wire in indoor applications? In indoor applications, CCA copper wire can have a long working life, similar to pure copper, as long as it is not exposed to harsh environmental conditions that could accelerate oxidation or brittleness.

- Are there any special installation considerations for CCA copper wire? During installation, care should be taken to avoid bending or twisting the wire excessively, as CCA copper wire can be more brittle than pure copper, leading to potential damage.

- How does the factorys address sustainability in CCA copper wire production? By combining aluminum with copper, our factory reduces the demand for pure copper, promoting resource conservation while delivering competitive and effective products.

- What packaging options are available for shipping CCA copper wire? The CCA copper wire is packaged in plastic drums for ease of handling and security during shipping, ensuring it arrives at its destination in optimal condition.

Product Hot Topics

- The Role of CCA Copper Wire in Modern TelecommunicationsFactorys CCA copper wire plays a crucial role in modern telecommunications by providing a cost-effective solution for long-distance signal transmission. While pure copper wire offers superior conductivity, the lightweight and budget-friendly nature of CCA copper wire makes it more accessible, particularly in regions where financial constraints are a significant concern. By facilitating the widespread installation of telecommunications infrastructure, factorys CCA copper wire helps bridge the digital divide, bringing connectivity to underdeveloped areas and enhancing communication capabilities globally.

- How CCA Copper Wire Contributes to Automotive EfficiencyIn the automotive industry, every ounce of weight saved can contribute to better fuel efficiency and performance. Factorys CCA copper wire offers a lightweight alternative to traditional copper wiring, reducing the overall weight of a vehicle's wiring systems. This weight reduction, although seemingly minor, can lead to significant improvements in fuel economy and decreased emissions, making CCA copper wire an attractive choice for car manufacturers aiming to produce more environmentally friendly and efficient vehicles.

- Innovations in Manufacturing Processes of CCA Copper WireTechnological advancements in the manufacturing processes of CCA copper wire have significantly enhanced its performance and reliability. Factorys embrace cutting-edge techniques like electroplating and cladding to ensure a uniform copper coating over the aluminum core, resulting in a wire that meets diverse industry standards for conductivity and durability. These innovations not only improve the quality and lifespan of CCA copper wire but also reduce production costs, making it a more viable solution across various sectors.

- Sustainability and Resource Efficiency with CCA Copper WireAs global industries move towards more sustainable practices, the use of CCA copper wire represents a step forward in resource efficiency. By reducing the reliance on pure copper, factorys contribute to the conservation of mineral resources, while still delivering high-performance products. This balance of sustainability and functionality makes CCA copper wire an ethical choice for companies committed to environmental stewardship.

- Comparing CCA Copper Wire with Other Wire TypesWhen evaluating wiring options, factorys CCA copper wire presents a compelling balance between cost, conductivity, and weight. Compared to other wire types, CCA wire offers a unique compromise—delivering adequate conductivity and durability without the high costs associated with pure copper. This makes it a preferred option for applications where budget constraints and weight considerations play a significant role.

- The Importance of Quality Control in CCA Copper Wire ProductionAt factorys, stringent quality control procedures are in place to ensure that every batch of CCA copper wire meets the required standards for performance and reliability. Adhering to ISO9001 and ISO14001 certifications, the production process involves meticulous testing at each stage—from the quality of raw materials to the final product inspection—ensuring that customers receive consistent and high-quality CCA copper wire.

- Exploring the Versatility of CCA Copper Wire in Various IndustriesFactorys CCA copper wire demonstrates remarkable versatility, being suitable for a wide range of applications across different industries. From telecommunications to automotive and construction, its adaptability is attributed to its unique blend of properties, offering a practical solution for scenarios where balancing cost, weight, and conductivity is essential. This versatility underpins its growing popularity and widespread adoption.

- Challenges and Solutions in CCA Copper Wire UtilizationWhile CCA copper wire offers numerous advantages, it also presents challenges, particularly in terms of brittleness and lower conductivity compared to pure copper. Factorys continually explores solutions to these challenges, focusing on enhancements in manufacturing techniques and material quality to improve product resilience and performance, ensuring that CCA copper wire remains a competitive and reliable choice.

- Evaluating the Cost-Benefit of CCA Copper Wire in Infrastructure ProjectsIn large-scale infrastructure projects, the use of factorys CCA copper wire can result in substantial cost savings without compromising on performance. Its affordability and adequate conductivity make it a suitable alternative to more expensive wiring options, allowing project managers to allocate resources more effectively and achieve budgetary targets while maintaining project quality.

- Understanding the Lifecycle of CCA Copper WireThe lifecycle of factorys CCA copper wire, from production to disposal, reflects a commitment to sustainability and resource efficiency. By utilizing a combination of materials, the wire's lifecycle is optimized for performance while minimizing environmental impact. Factorys emphasizes responsible manufacturing and recycling practices to enhance product sustainability, ensuring that the lifecycle of CCA copper wire aligns with modern environmental goals.

Image Description