Product Main Parameters

| Parameter | Value |

|---|---|

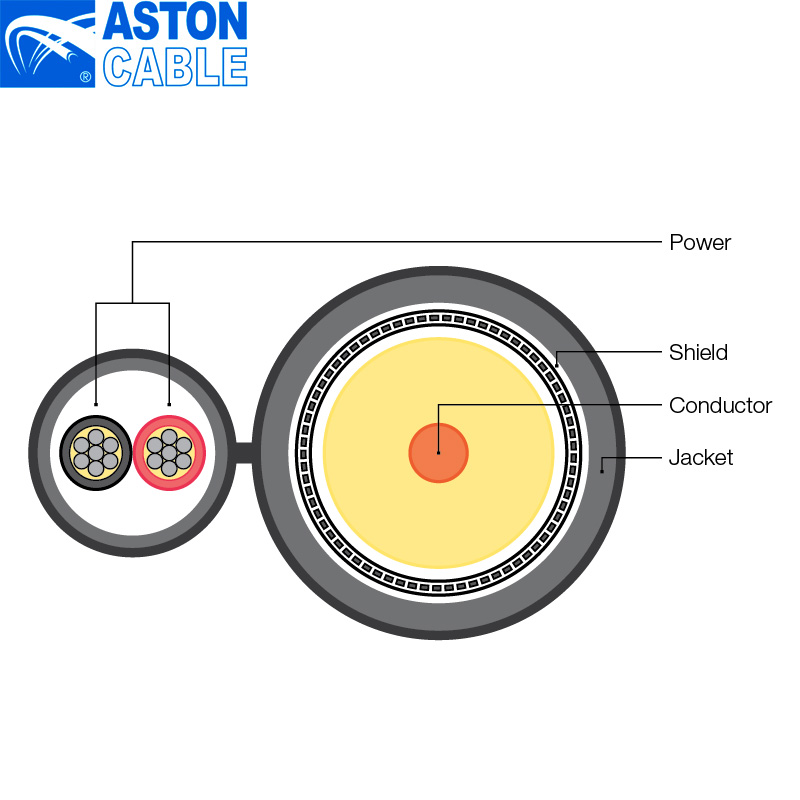

| Center Conductor | 1.02mm 18AWG bare copper |

| Jackets | PVC, LSZH, PE |

| Color | Customized |

| Connector | BNCDC |

| Daily Output | 200KM |

Common Product Specifications

| Specification | Details |

|---|---|

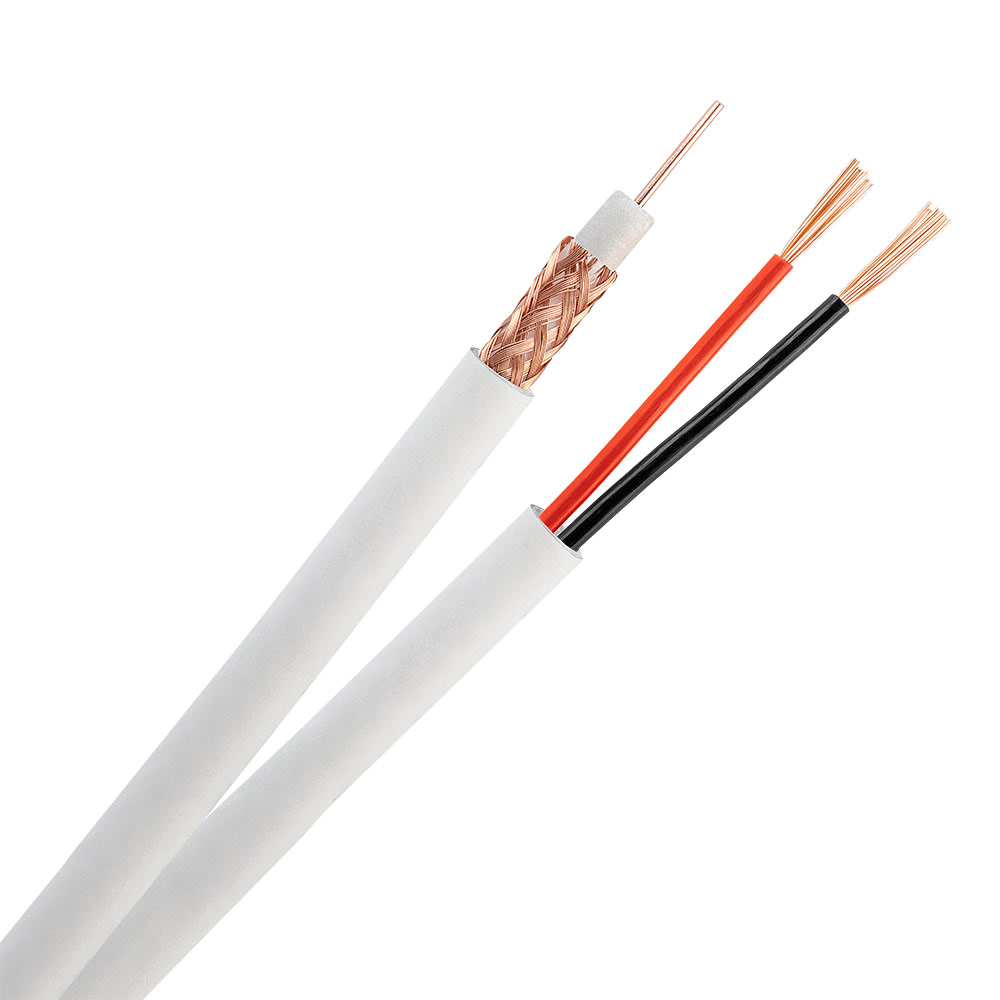

| Type | RG6 with power cable |

| Weight | 6.0KG/100m |

| Conductors | 100% Copper Dielectric 4.6FPE |

| Packages | Coil reel, plastic drum, wooden drum, color boxes, carton boxes |

Product Manufacturing Process

The manufacturing process of our factory Siamese cable CCTV involves several critical stages to ensure high-quality production. Initially, raw copper materials are procured and subjected to rigorous quality checks. The copper is then drawn and annealed to achieve the desired diameter for the center conductor, which is a crucial step for maintaining signal fidelity. Concurrently, dielectric insulation materials are prepared and carefully extruded around the copper to provide optimal impedance characteristics. The next phase involves braiding, where the cable is equipped with a braid shield for electromagnetic interference protection. Following this, the power conductors are integrated alongside the coaxial component to complete the Siamese configuration. The finished cables undergo stringent testing for electrical performance, mechanical strength, and environmental resistance to confirm compliance with industry standards. Finally, the products are packaged according to client specifications, ensuring safe and efficient delivery.

Product Application Scenarios

Siamese cables from our factory are utilized extensively in systems requiring simultaneous transmission of video and power, such as CCTV and surveillance installations. Their dual-purpose design facilitates ease of installation, rendering them ideal for both residential and commercial security systems. In residential settings, Siamese cables can effectively support home surveillance cameras, delivering reliable video feeds while supplying necessary power to the devices. Commercially, these cables are deployed in larger monitoring systems, such as those found in retail spaces or corporate offices, where centralized power and video distribution is critical. Their robust construction ensures performance stability, even in outdoor environments, making them suitable for perimeter surveillance in industrial facilities. The integration of both video and power in a single cable streamlines system architecture, reducing clutter and potential points of failure.

Product After-Sales Service

We provide comprehensive after-sales service for all factory Siamese cable CCTV products, including technical support, product replacement, and warranty claims. Our dedicated customer service team is available to assist with any inquiries or issues, ensuring a satisfactory experience for our clients. Additionally, we offer guidance on installation and maintenance to maximize the lifespan and performance of our cables.

Product Transportation

Our factory Siamese cable CCTV products are packaged with care to withstand the rigors of transportation. We offer standard export packaging, with options for coil reels, plastic drums, or wooden drums as required. Delivery is handled through reputable shipping partners, ensuring timely and secure arrival at the designated port, typically Ningbo, with adherence to international shipping standards.

Product Advantages

- Efficiency: Combining power and video transmission reduces installation complexity and time.

- Cost-Effective: Fewer cables lead to reduced material and labor costs.

- Durability: Weather-resistant materials provide longevity in diverse environments.

- Organization: Minimizes clutter, facilitating a neat and orderly setup.

Product FAQ

1. What is a Siamese cable?

A Siamese cable is a type of cable used in CCTV installations, combining both video and power transmission lines into a single cable.

2. What is the advantage of using Siamese cable?

The primary advantage is the convenience of running both power and video through one cable, simplifying installation.

3. What are the material components of Siamese cable?

Siamese cable typically consists of a coaxial cable for video signals and power wires for electricity, composed of copper conductors.

4. Is the cable suitable for outdoor use?

Yes, our factory Siamese cable CCTV products are weather-resistant and suitable for outdoor use.

5. What is the maximum distance for video quality?

Siamese cables can support video transmission up to 750 feet without degradation.

6. Can I customize the cable color?

Yes, we offer options for customized cable colors to suit specific installation needs.

7. What is the MOQ for ordering?

The minimum order quantity is 30km, allowing for cost-effective production and supply.

8. What certifications do these cables have?

Our cables are certified according to SGS, CE, ROHS, and ISO9001 standards.

9. What kind of connectors are used?

BNC and DC connectors are standard for our Siamese cable CCTV products.

10. How can I ensure compatibility with my CCTV system?

It's important to check the voltage requirements and video standards of your system to ensure proper compatibility with our cables.

Product Hot Topics

1. Installation Tips for Factory Siamese Cable CCTV

When installing factory Siamese cable CCTV systems, consider the layout and distance between cameras and the central monitoring station. Ensure the cable is properly secured and avoid sharp bends that could damage the conductors. Proper grounding is essential to prevent interference and maintain signal quality. Testing the system after installation ensures everything is functioning correctly, allowing for any necessary adjustments.

2. Comparing Factory Siamese Cable CCTV to Other Options

The choice between using factory Siamese cable CCTV systems and alternative cabling options largely depends on the specific needs of the installation. For smaller setups, the simplicity and cost-effectiveness of Siamese cables are unmatched. However, for longer distances or more complex systems, fiber optic cables might be more appropriate due to their superior signal integrity over long runs. Each option has its pros and cons, so a thorough assessment of the site and budget is crucial.

3. Maintenance Best Practices for Factory Siamese Cable CCTV

Regular maintenance of factory Siamese cable CCTV systems includes checking for physical damage to the cables, ensuring all connections are secure, and verifying the performance of the surveillance system. Cleaning the camera lenses and housings is also important to maintain clear video feeds. Periodic testing and recalibration may be necessary as well, particularly in environments with fluctuating temperatures or humidity levels.

4. Enhancing Signal Quality in Factory Siamese Cable CCTV

To maintain optimal signal quality in factory Siamese cable CCTV installations, ensure all connections are tight and free of corrosion. Using high-quality connectors and components will also reduce the risk of signal interference. In environments with a lot of electronic equipment, proper shielding and grounding are critical to prevent electromagnetic interference, which can degrade video quality.

5. Environmental Considerations for Factory Siamese Cable CCTV

When installing factory Siamese cable CCTV systems outdoors, choosing cables with UV-resistant and weatherproof jackets is vital to withstand environmental conditions. In regions with extreme temperatures, consider using cables capable of functioning in a wide temperature range. Monitoring the condition of the cables regularly can preempt accidental failures caused by environmental factors.

6. Technological Advances in Factory Siamese Cable CCTV

Recent advancements in factory Siamese cable CCTV technology include improved shielding techniques to reduce interference and enhance signal quality. Innovations in cable materials have also led to increased durability and flexibility, allowing for easier installations in tight spaces. Additionally, manufacturers are continually developing cables that support higher bandwidths to cater to the demand for high-definition video surveillance.

7. Security Implications of Factory Siamese Cable CCTV

Utilizing factory Siamese cable CCTV systems provides a robust security solution for both residential and commercial applications. The combination of video and power in a single cable offers efficiency and ease of installation, reducing the potential for system failures. By ensuring the cameras are strategically placed and adequately powered, facilities can achieve comprehensive surveillance coverage and enhanced security.

8. Cost Analysis of Factory Siamese Cable CCTV Systems

When performing a cost analysis of factory Siamese cable CCTV systems, consider both the initial purchase cost and long-term operational savings. The reduction in installation time and material costs can result in significant savings for extensive systems. Over time, the reliability and low maintenance needs of Siamese cables can further contribute to lower operating costs, providing a compelling return on investment.

9. Customization Options for Factory Siamese Cable CCTV

At our factory, we offer extensive customization options for Siamese cable CCTV systems, including cable color, length, and connector type. This flexibility allows clients to tailor their surveillance solutions to meet specific requirements for different environments and applications. Customization ensures the system seamlessly integrates with existing infrastructure, delivering optimal performance and aesthetics.

10. User Experiences with Factory Siamese Cable CCTV Systems

Users of factory Siamese cable CCTV systems often report satisfaction with the ease of installation and reliability of the product. The dual-purpose nature of the cable simplifies setup and reduces potential points of failure, resulting in fewer issues over time. Positive feedback highlights the cable's durability in various environments, including extreme weather conditions, where performance remains stable and reliable.

Image Description