Product Details

| Parameter | Details |

|---|---|

| Product Name | Stranded Copper Clad Aluminum Wire |

| Sizes | 0.12mm-3.0mm |

| Color | Copper color |

| Packages | Plastic drum |

| Usage | Cable conductor |

| Logo | OEM |

| Industrial Use | Conductor or braiding |

| Origin | Hangzhou, Zhejiang |

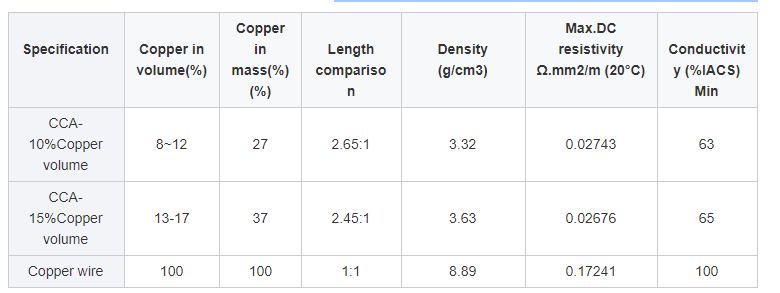

Common Product Specifications

| Specification | Description |

|---|---|

| Coaxial Cable Daily Output | 200KM |

| Minimum Order Quantity | 30km |

| Supply Ability | 25000KM/Per year |

| Delivery Port | Ningbo |

Product Manufacturing Process

The manufacturing process of stranded copper clad aluminum wire begins with selecting high-grade aluminum for the core, which is then tightly bonded with a thin layer of copper through cladding or electroplating techniques. This process ensures a high-quality mechanical and metallurgical bond that enhances the wire's electrical conductivity and corrosion resistance. The stranded version is created by twisting multiple individual wires together, providing flexibility and resistance to metal fatigue. This combination of processes results in a wire that maintains the electrical properties of copper with the lightweight and cost benefits of aluminum, ideal for bulk applications.

Product Application Scenarios

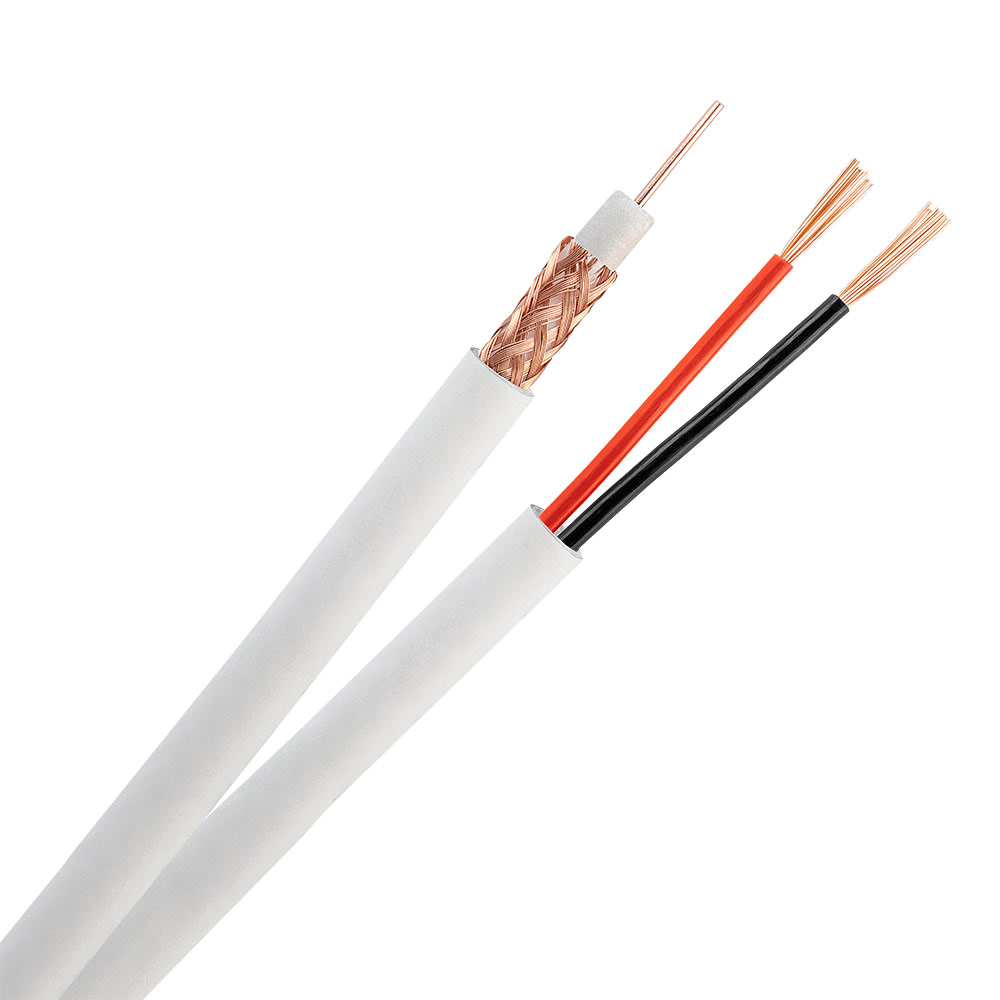

Stranded copper clad aluminum wire is widely used in telecommunications, automotive, and residential wiring. In telecommunications, it supports the creation of coaxial and network cables, offering a cost-effective solution with acceptable performance metrics. In automotive industries, its lightweight nature aids in enhancing vehicle performance and fuel efficiency. Residential wiring applications benefit from its budget-friendly characteristics, providing an affordable option for construction projects with financial constraints. These scenarios utilize stranded copper clad aluminum wire for its blend of economic and functional advantages, although selection should consider specific requirements for conductivity and mechanical strength.

Product After-Sales Service

Our factory ensures comprehensive after-sales service, including technical support for optimal utilization of stranded copper clad aluminum wire. Customers can expect prompt assistance for product queries or issues, a testament to our commitment to customer satisfaction.

Product Transportation

Products are packaged in plastic drums for secure transport and shipped via Ningbo port. We ensure timely delivery schedules matched to client needs and logistical arrangements.

Product Advantages

- Cost Efficiency: Combines copper's conductivity with aluminum's affordability.

- Lightweight: Reduces weight, aiding in applications like automotive and aerospace.

- Corrosion Resistance: Copper coating enhances lifespan against environmental exposure.

Product FAQ

- What is the main advantage of using stranded copper clad aluminum wire from your factory?

Our stranded copper clad aluminum wire offers a cost-effective and lightweight alternative to pure copper wires, making it ideal for applications where budget and weight are critical considerations. The factory ensures high-quality production with adherence to industry standards, resulting in reliable performance.

- How does the conductivity of stranded copper clad aluminum wire compare to pure copper wire?

While not as conductive as pure copper, the copper cladding in stranded copper clad aluminum wire significantly improves its conductivity compared to aluminum alone. It suffices for many applications, balancing efficiency with cost.

- Can I customize the wire size for specific applications?

Yes, our factory produces stranded copper clad aluminum wire in sizes ranging from 0.12mm to 3.0mm, tailored to meet diverse application needs such as telecommunications and automotive industries.

- What support does your factory offer for installation and usage?

We provide comprehensive technical support to guarantee the effective use of stranded copper clad aluminum wire. Our team is equipped to assist with any installation or performance queries to ensure client satisfaction.

- Do you offer OEM branding for stranded copper clad aluminum wire?

Yes, OEM branding is available for stranded copper clad aluminum wire, allowing businesses to incorporate their branding needs, enhancing market presence and recognition.

- What environmental benefits does stranded copper clad aluminum wire offer?

By using aluminum as the core material, our factory reduces overall resource consumption. The lightweight nature also contributes to transportation efficiency, providing environmental benefits.

- What industries most commonly use stranded copper clad aluminum wire?

Industries such as telecommunications, automotive, and residential construction frequently use stranded copper clad aluminum wire for its balance between cost and performance. It is particularly beneficial where weight reduction and budget constraints are priorities.

- What shipping options are available from your factory?

We offer secure packaging using plastic drums and shipment through Ningbo port. Our logistics are designed to ensure timely delivery in accordance with customer schedules.

- How does the factory ensure quality control for stranded copper clad aluminum wire?

Our factory is equipped with state-of-the-art manufacturing machines and employs rigorous quality control systems aligned with ISO standards, ensuring each batch of stranded copper clad aluminum wire meets the highest industry criteria.

- Are your products environmentally compliant?

Yes, our stranded copper clad aluminum wires are RoHS compliant, ensuring minimal environmental impact and aligning our operations with sustainable practices.

Product Hot Topics

- Cost-Effective Wiring Solutions

In today's market, the demand for cost-effective wiring solutions is growing. Stranded copper clad aluminum wire from our factory offers an excellent alternative to pure copper wire. By providing similar performance at a reduced cost, it meets the economic needs of various industries. It’s particularly beneficial in telecommunications and automotive sectors where budget and efficiency are essential. The factory's commitment to quality and customer satisfaction ensures that these wires not only meet but exceed expectations while staying within budget constraints.

- Weight Reduction in Automotive Industry

The automotive industry constantly seeks innovations to reduce vehicle weight and enhance performance. Stranded copper clad aluminum wire serves as an optimal solution due to its lightweight nature. Factories producing this wire cater to automotive requirements by ensuring high strength without compromising vehicle efficiency. As manufacturers aim to meet stringent fuel efficiency regulations, transitioning to lighter materials like stranded copper clad aluminum wire becomes a strategic decision.

- Enhancing Telecommunication Networks

With the expansion of global telecommunication networks, the demand for effective and affordable cabling solutions is at an all-time high. Stranded copper clad aluminum wire from factories offers a viable alternative to traditional cables, providing excellent signal transmission qualities at a lower cost. This solution enables network providers to extend infrastructure without excessive expense, facilitating widespread communication access, especially in underdeveloped areas.

- Sustainable Wiring Practices

As industries push towards sustainability, using eco-friendly materials becomes crucial. Our factory’s production of stranded copper clad aluminum wire aligns with this trend, offering environmentally compliant products that reduce copper usage and promote sustainable practices. The choice of materials in manufacturing impacts ecological footprints significantly, and opting for copper clad aluminum demonstrates a commitment to responsible resource management.

- Electrical Conductivity vs. Cost

Balancing conductivity with cost efficiency is pivotal in electrical applications. Our factory-produced stranded copper clad aluminum wire presents a practical compromise. While pure copper offers superior conductivity, the copper clad version provides competent performance at a fraction of the cost. Evaluating the trade-off is essential for industries weighing operational costs against electrical efficiency.

- Adapting to Diverse Application Needs

Diversity in application demands adaptability in product offerings. Stranded copper clad aluminum wire, available in various sizes, caters to different industry requirements, making it a preferred choice for manufacturers. Our factory’s capability to customize wire specifications ensures compatibility with specific client applications, enhancing operational workflow.

- Quality Assurance in Wiring Production

Quality assurance is a cornerstone of manufacturing processes in our factory. Each strand of copper clad aluminum wire undergoes rigorous testing to meet international standards. Customers can trust the consistency and reliability of our products, knowing they are backed by comprehensive quality control systems.

- OEM Opportunities for Custom Branding

In competitive markets, branding plays a crucial role. Our factory offers OEM services for stranded copper clad aluminum wire, allowing businesses to tailor products to their brand's identity. Custom branding helps companies differentiate themselves, creating unique market positioning while maintaining product quality and performance.

- Technological Advances in Cable Production

Technological advancements are reshaping cable production methods. Our factory invests in state-of-the-art technology to enhance the manufacturing of stranded copper clad aluminum wire, ensuring high precision and quality. This commitment to innovation allows us to meet evolving market demands efficiently.

- Corrosion Resistance Benefits

The copper layer in stranded copper clad aluminum wire provides a protective barrier against corrosion, a critical advantage in many applications. Industries with exposure to harsh environments benefit from this durability, ensuring long-lasting performance and reduced maintenance costs. Our factory emphasizes producing corrosion-resistant wiring that stands the test of time in demanding settings.

Image Description