Product Main Parameters

| Part No. | No. Cores | Conductor Area (mm2) | Overall Diameter (mm) | Weight (kg/km) | Copper Resistance (Ω/km) |

|---|---|---|---|---|---|

| 2C0.75YY | 2 | 0.75 | 5.9 | 50 | 26.0 |

| 3C1.5YY | 3 | 1.5 | 7.2 | 95 | 13.3 |

| 5C4.0YY | 5 | 4.0 | 13.7 | 355 | 4.95 |

Common Product Specifications

| Jacket | Color | Usage | Logo |

|---|---|---|---|

| LSZH | Gray | Control | OEM |

Product Manufacturing Process

Based on research conducted in authoritative papers, the manufacturing process of control cable wire involves multiple stages to ensure quality and durability. The conductors are drawn through dies to achieve the desired diameter and flexibility, which are then annealed to enhance conductivity. Insulation is applied using extrusion methods, where materials like PVC or XLPE are melted and coated around the conductors. A protective sheath is added to the insulated conductors, further enhancing the cable's environmental resistance. Rigorous testing procedures, including voltage and insulation resistance tests, ensure compliance with international standards. Technological advancements in manufacturing have led to improved precision and consistency, making control cables suitable for a wide range of industrial applications.

Product Application Scenarios

According to recent studies, control cable wire is essential in numerous application scenarios. In industrial automation, it connects sensors and actuators for efficient system operations. The transportation sector utilizes these cables for reliable control in ECUs and braking systems. Building management systems rely on control cables for seamless integration of HVAC and security systems. In the energy sector, they play a crucial role in controlling equipment in power plants and renewable setups. The versatility and robustness of factory-manufactured control cables make them indispensable in facilitating smooth and reliable operations across diverse environments.

Product After-Sales Service

Aston Cable Factory provides comprehensive after-sales services, including installation guidance, technical support, and warranty coverage for control cable wires. Our dedicated team ensures prompt resolution of any issues, consistent with our commitment to customer satisfaction.

Product Transportation

Our control cable wires are securely packaged for transportation to prevent damage. We partner with reliable logistics providers to ensure timely delivery, with tracking available for all orders.

Product Advantages

- Reliability: Ensures stable and accurate signal transmission.

- Flexibility: Available in various configurations for diverse applications.

- Environmental Resistance: Withstands extreme conditions, ensuring longevity.

Product FAQ

- What is the minimum order quantity? The minimum order quantity for control cable wires from our factorys is 30 km.

- Are the cables RoHS compliant? Yes, our control cable wires comply with RoHS standards, ensuring they are environmentally friendly.

- How long is the delivery time? Delivery time varies based on location, but we strive to ship within 2-4 weeks.

- Can you customize the cable design? Yes, our factorys offer OEM services to tailor control cable wire specifications to your needs.

- What certifications do your cables have? Our control cable wires are certified with CE, ISO9001, and other relevant standards.

- How do you ensure quality control? We implement rigorous testing throughout production to maintain high standards.

- What warranty is available? We offer a comprehensive warranty covering manufacturing defects and related issues.

- Are these cables suitable for outdoor use? Yes, when properly protected, these cables can be used outdoors.

- What is the operating temperature range? The cables operate efficiently in a temperature range suitable for most industrial applications.

- How should I store unused cables? Store cables in a cool, dry environment to maintain their integrity and performance.

Product Hot Topics

- Advancements in Factorys Control Cable Wire Manufacturing

The evolution of technology has significantly impacted the manufacturing processes of control cable wires in factory settings. Automation and precision machinery have streamlined production and enhanced the quality and consistency of these cables. Innovations in insulation materials have also improved the environmental resistance and durability of control cables. This progress not only meets the increasing demands of industrial applications but also aligns with environmental and safety standards. As factory capabilities expand, the industry can anticipate further enhancements in cable performance and versatility.

- Role of Control Cable Wires in Smart Factories

In the era of Industry 4.0, control cable wires play a crucial role in smart factory environments. They enable seamless communication between machines, sensors, and control systems, facilitating real-time data transmission and analysis. This capability is essential for maintaining efficient and responsive manufacturing processes. The integration of advanced control cables supports the shift towards more automated, interconnected factory operations, contributing to improved productivity and reduced downtime.

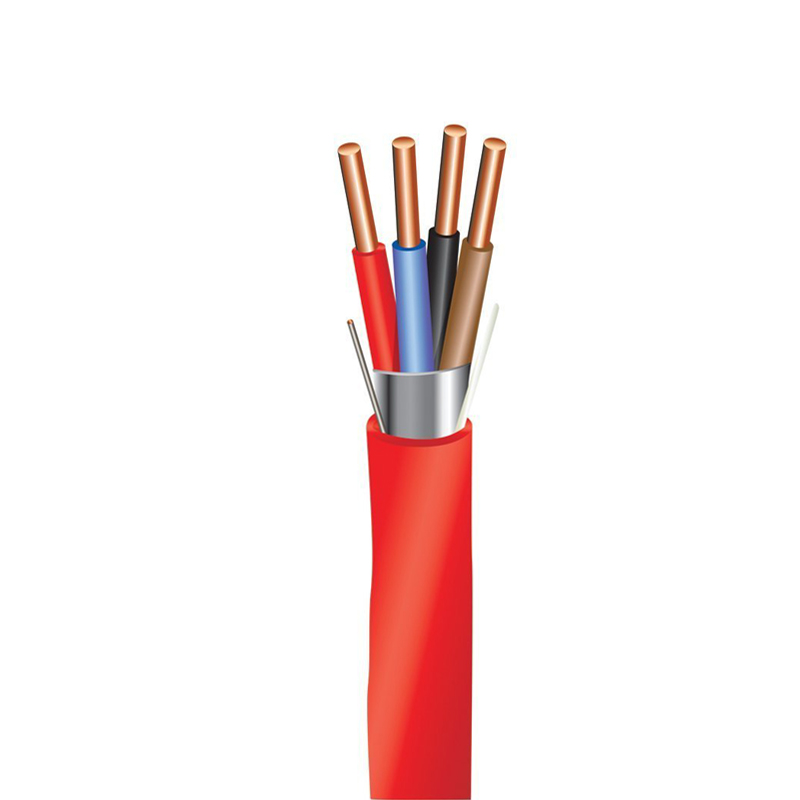

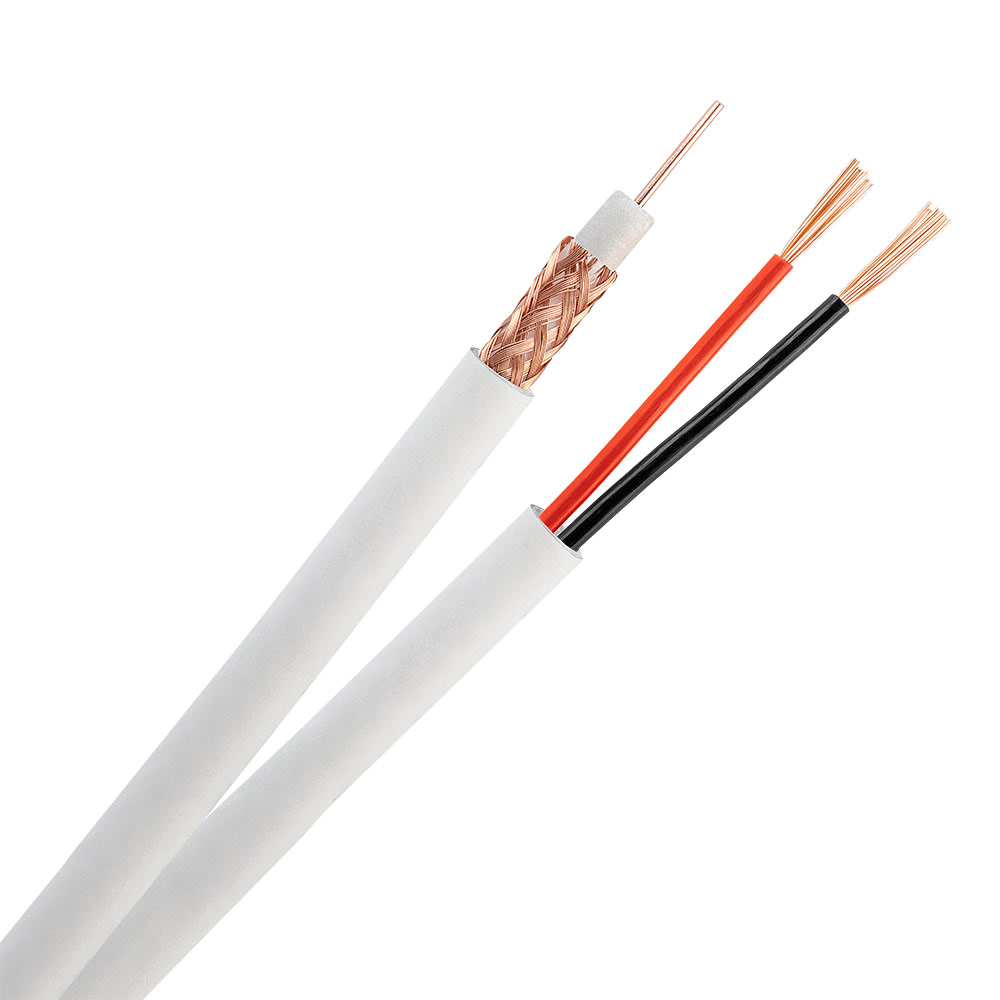

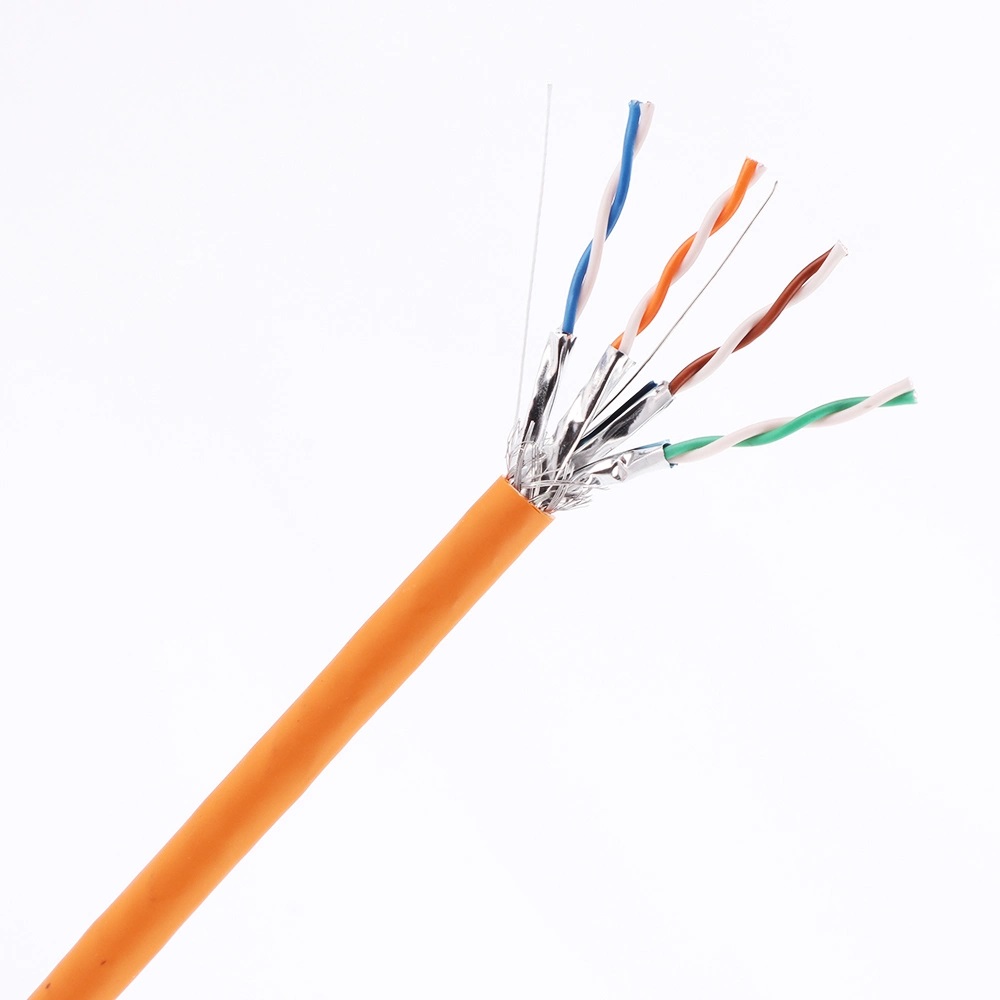

Image Description