Product Details

| Attribute | Specification |

|---|---|

| Conductor | Class 5 flexible annealed plain copper |

| Insulation | LSZH |

| Colors | Gray |

| MOQ | 30KM |

| Capacity | 500km per day |

| Certification | SGS, CE, ROHS, ISO9001 |

| Origin | Hangzhou, Zhejiang |

Common Product Specifications

| Part No. | No. Cores | Cross Section Area(mm²) | Overall Diameter(mm) | Nominal Weight(kg/km) | Resistance(Ω/km at 20℃) |

|---|---|---|---|---|---|

| 2C0.75YY | 2 | 0.75 | 5.9 | 50 | 26.0 |

Product Manufacturing Process

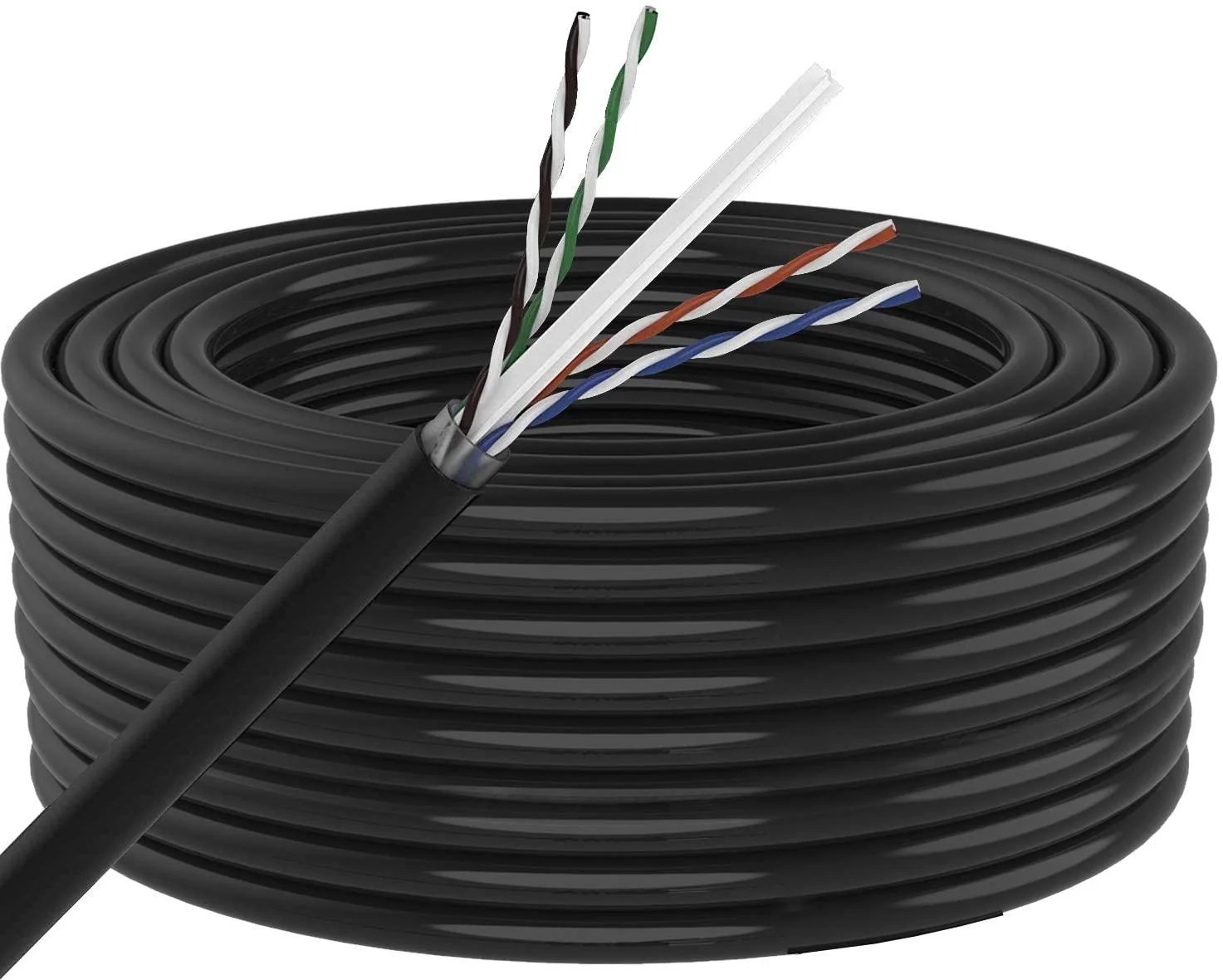

The manufacturing of factorys shielded control cables involves several key processes to ensure quality and performance. Initially, high-grade copper is drawn and annealed to increase its flexibility. This conductor core is then insulated using cross-linked polyethylene, providing excellent electrical insulation properties. The critical shielding layer comprises a blend of aluminum foil and copper braiding, which effectively blocks electromagnetic interference. Finally, an LSZH jacket encases the assembly, offering robust environmental protection. Advanced testing methods confirm compliance with international standards, ensuring the factory's cables deliver consistent and reliable performance in demanding applications.

Product Application Scenarios

Factorys shielded control cables are pivotal in high-interference environments such as industrial automation and data centers. In industrial automation, these cables ensure uninterrupted data flow and operational reliability by mitigating EMI effects from heavy machinery. In data centers, their use is critical as they prevent crosstalk and signal losses in densely packed equipment environments, thus enhancing network reliability. Moreover, shielded cables are vital in medical environments where precision and data integrity can significantly influence patient outcomes, ensuring equipment functions accurately without electromagnetic disturbances.

Product After-Sales Service

- 24/7 Customer Support

- Warranty Claims

- Technical Assistance

- Replacement and Refund

Product Transportation

- International Shipping Available

- Secure Packaging Ensured

- Delivery Time: 4-6 Weeks

- Shipping Port: Ningbo

Product Advantages

- Superior EMI Protection

- Durable and Flexible

- Complies with International Standards

- Wide Industrial Applications

Product FAQ

- What is the purpose of a shielded control cable?

The factorys shielded control cable is designed to prevent electromagnetic interference that could disrupt electronic equipment's performance, ensuring reliable signal transmission. - What materials are used for the shielding?

The factorys shielded control cable uses a combination of aluminum foil and copper braiding for effective EMI protection. - Are these cables waterproof?

While the factorys shielded control cable is not explicitly waterproof, its LSZH jacket provides substantial moisture resistance for indoor and controlled outdoor use. - What certifications do these cables have?

The factorys shielded control cable is certified by SGS, CE, ROHS, and ISO9001, ensuring compliance with international quality and safety standards. - Can these cables be used in high-temperature environments?

The LSZH jacket and cross-linked polyethylene insulation allow the factorys shielded control cable to perform well in moderately high temperatures, but not in extreme heat. - What are the installation recommendations for these cables?

Installation should be performed by skilled technicians to ensure proper termination and grounding for maximized EMI protection. - Are these cables customizable?

Yes, factorys shielded control cables can be customized for specific requirements, including length, number of conductors, and additional shielding. - How flexible are these cables?

They are designed to offer a balance of flexibility and protection, suitable for most industrial and data center applications without hindrance. - What are the primary applications for these cables?

Factorys shielded control cables are primarily used in environments with high EMI, like industrial automation, data centers, telecommunications, and medical equipment. - How does the cable ensure data integrity?

By using shield materials and configurations that block EMI, the factorys shielded control cable ensures that signals remain clear and precise during transmission.

Product Hot Topics

- Why EMI protection matters in industrial settings?

In modern industrial environments, electromagnetic interference (EMI) can severely impact the performance and reliability of electronic devices. The factorys shielded control cable is engineered to counteract these influences, ensuring that signal integrity is maintained, which is critical for automation processes where precision is paramount. With EMI protection, factories can minimize equipment malfunctions and downtime, leading to improved productivity and efficiency. - Shielded Control Cable: A Data Center Essential

Data centers are hubs of massive data exchange, with a multitude of cables transmitting critical information. The factorys shielded control cable is integral in these settings due to its ability to minimize crosstalk and interference, thereby protecting the integrity of data. This ensures reliable and uninterrupted data flow, essential for maintaining operational continuity and the overall performance of IT infrastructure.

Image Description