Product Main Parameters

| Parameter | Details |

|---|---|

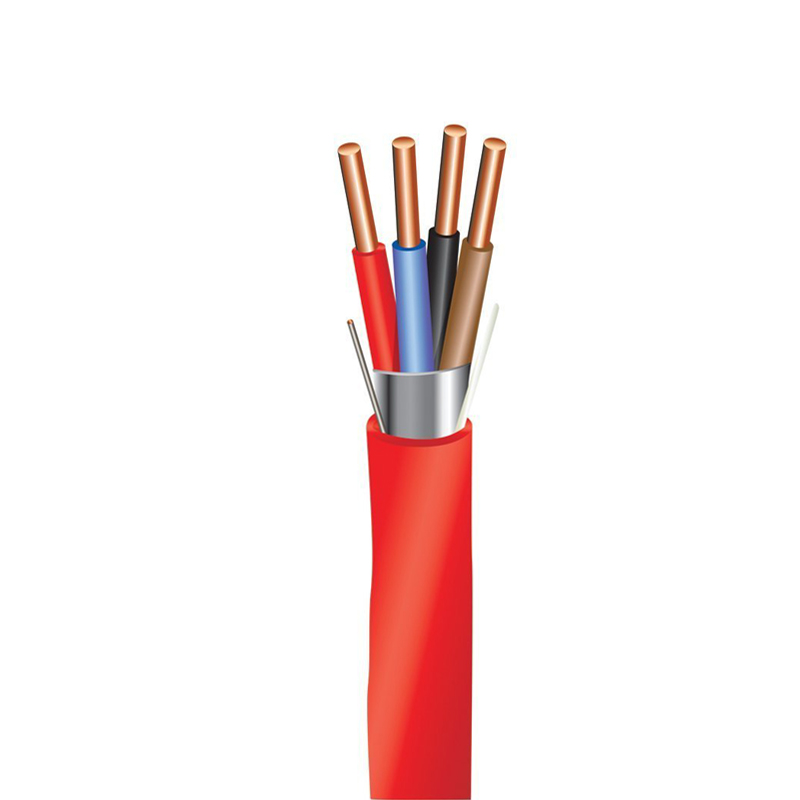

| Conductor | Solid bare copper |

| Insulation | 18-16AWG, 14-12AWG |

| Jacket | Low smoke PVC |

| Shield | Aluminum Mylar |

| Voltage Rating | 300V |

| Temp. Rating | -5℃ to 75℃ |

| Drain Wire | 24 AWG |

Common Product Specifications

| Specification | Details |

|---|---|

| Origin | Hangzhou, Zhejiang, China |

| Certification | SGS, CE, ROHS, ISO9001 |

| Color | Red |

| Daily Output | 200KM |

| MOQ | 30km |

Product Manufacturing Process

Drawing from authoritative sources in cable manufacturing, our alarm cables follow a rigorously controlled process. This process begins with selecting high-quality raw materials, primarily Oxygen-Free Copper (OFC), to ensure superior conductivity. The copper is drawn into wires through a series of dies to achieve the desired gauge. The wires are then insulated with low smoke PVC to enhance fire resistance and safety. Next, the insulated wires are stranded or braided to form the core structure of the cables. A shielding layer of Aluminum Mylar is applied to reduce electromagnetic interference (EMI). The final step involves adding a durable outer jacket, typically using PVC or LSZH materials, to provide mechanical protection and environmental resistance. Each stage includes thorough quality checks to guarantee compliance with international standards like IEC, ensuring reliable performance in security applications.

Product Application Scenarios

According to industry literature, our alarm cables are essential in multiple security applications. They form the backbone of Intrusion Detection Systems by connecting sensors and control panels, ensuring prompt alerts for unauthorized access. In Fire Alarm Systems, these cables link smoke detectors and manual call points to central monitoring units, enabling immediate fire response. CCTV installations also benefit from our cables, as they handle power and auxiliary data alongside primary video feeds. Access Control Systems use these cables to manage communication between entry devices and management systems, maintaining efficient operational security. The versatility and reliability of our alarm cables make them suitable for residential, commercial, and industrial security setups, highlighting their importance in safeguarding assets and premises.

Product After-Sales Service

- 24/7 Customer Support: Our team is available around the clock to address any technical issues or queries you might have regarding our alarm cables.

- Warranty Policy: We offer a comprehensive warranty on our products to ensure customer satisfaction and trust in our brand.

- Installation Guidance: Our experienced technicians provide detailed installation manuals and support to ensure optimal performance and compliance with safety standards.

Product Transportation

Our alarm cables are meticulously packaged for transport, with standard export packaging to withstand international shipping conditions. We offer delivery through the Ningbo port, ensuring timely and efficient shipment to various global destinations. Our logistics partners are experienced in handling security products, ensuring that packages are secure and tracked until they reach your doorstep.

Product Advantages

- High Conductivity: Made with OFC copper for optimal electrical performance.

- Fire Resistance: Designed to function reliably under fire conditions, ensuring safety.

- Compliance: Meets international standards, including IEC, SGS, and CE certifications.

- Versatile Applications: Suitable for a wide range of security systems, enhancing system integrity.

- Durable Construction: Features a robust outer jacket for mechanical protection and longevity.

Product FAQ

- What makes your alarm cables superior to others in the market?

As a manufacturer with over 20 years of experience, our alarm cables are built with high-quality materials and a stringent production process, ensuring high conductivity and fire resistance. We prioritize compliance with international standards, guaranteeing superior performance and reliability in various security applications.

- Are your alarm cables suitable for outdoor use?

Yes, our sheathed alarm cables are designed to withstand outdoor conditions. They have an additional protective layer that ensures durability and resistance to mechanical stress, making them suitable for both indoor and outdoor security installations.

- What is the typical lead time for orders?

The lead time for orders varies based on quantity and specifications. However, we maintain a supply ability of 25,000 KM per year, allowing us to fulfill orders efficiently. Once an order is placed, we provide an estimated delivery schedule.

- Can your alarm cables handle high voltage systems?

Our alarm cables are rated at 300V, which is suitable for most low voltage security systems. It's important to match the cable to the specific voltage requirements of your system to ensure safe and efficient operation.

- What are the recommended storage conditions for your alarm cables?

To preserve the quality of our alarm cables, store them in a cool, dry place away from direct sunlight and extreme temperatures. Keeping them in their original packaging until installation is also advised to prevent any physical damage.

- Do you offer customization for alarm cables?

Yes, as a manufacturer, we offer customization options for our alarm cables to meet specific customer requirements. This includes variations in insulation, jacket material, and conductor gauge, among others.

- How do you ensure the quality of your alarm cables?

Quality assurance is integral to our manufacturing process. We implement rigorous quality checks at each production stage, from raw material selection to final product inspection. This ensures our alarm cables meet and exceed international standards.

- What specific certifications do your alarm cables hold?

Our alarm cables are certified by leading industry standards, including ISO9001, ISO14001, CE, RoHS, and IEC, verifying their safety, reliability, and environmental compliance.

- Are your alarm cables resistant to electromagnetic interference?

Yes, our screened alarm cables have a shielding layer of Aluminum Mylar that effectively minimizes electromagnetic interference, ensuring reliable signal transmission even in environments with high electrical noise.

- What is your policy on returns or exchanges?

We offer a flexible return and exchange policy for our alarm cables, aiming for complete customer satisfaction. If a product does not meet the specified standards, customers can contact our support team to initiate a return or exchange process.

Product Hot Topics

- Why Fire Resistance in Alarm Cables is Crucial: Insights from a Manufacturer

Fire resistance in alarm cables is a critical feature that enhances safety in emergencies. As a manufacturer, we prioritize this element to ensure that security systems remain functional during a fire, allowing for timely alerts and evacuation. Our cables are designed to maintain integrity under high temperatures, making them essential for installations in public buildings and high-risk areas where human safety is paramount.

- The Role of Multi-core Alarm Cables in Modern Security Systems

Modern security systems rely heavily on multi-core alarm cables to connect various components efficiently. As a leading manufacturer, we recognize the importance of these cables in facilitating simultaneous transmission of multiple signals, enhancing system reliability and integration. By providing multi-core options, we cater to complex installations that require comprehensive connectivity solutions, ensuring optimal performance and security.

- How Our Manufacturer Ensures Quality in Alarm Cables

As a dedicated manufacturer, quality assurance is at the forefront of our production process for alarm cables. We employ state-of-the-art equipment and adhere to stringent quality control protocols at each manufacturing stage. Our commitment to excellence is reflected in the certifications our products hold, such as ISO9001 and RoHS, which affirm their safety, reliability, and environmental compliance.

- Understanding Screened Alarm Cables: A Manufacturer's Perspective

Screened alarm cables are essential in environments with high levels of electromagnetic interference (EMI). As a manufacturer, we incorporate Aluminum Mylar shielding in our cables to safeguard signal integrity. This feature prevents false alarms and enhances system stability, making our screened cables ideal for industrial and commercial applications where electrical noise is prevalent.

- The Importance of Compliance for Alarm Cables by a Manufacturer

Compliance with international standards is non-negotiable in the production of alarm cables. Our manufacturing process strictly aligns with IEC, CE, and other certifications, ensuring our products meet global safety and performance benchmarks. This commitment to compliance assures customers of the quality and reliability inherent in our alarm cables.

- Insights into Alarm Cable Applications from a Leading Manufacturer

Our alarm cables are versatile, serving various security applications from intrusion detection to fire alarms. As a manufacturer, we design cables that integrate seamlessly into different systems, providing reliable connectivity and performance. The adaptability of our cables to suit diverse environments underscores their importance in comprehensive security solutions.

- Advantages of Low Smoke Zero Halogen (LSZH) Jackets in Alarm Cables

LSZH jackets offer significant safety advantages in alarm cables by reducing toxic smoke and fumes during a fire. As a manufacturer, we incorporate LSZH materials to enhance the safety profile of our cables, particularly in enclosed or public spaces. This feature is crucial in minimizing health risks and ensuring safe evacuation during emergencies.

- The Evolution of Alarm Cable Design: A Manufacturer's Insights

The design of alarm cables has evolved to meet increasing demands for safety, efficiency, and reliability. As a manufacturer, we continuously innovate to incorporate advanced materials and technologies that enhance cable performance. Our focus on R&D ensures our products stay ahead of industry trends, providing customers with cutting-edge solutions for their security needs.

- Exploring the Manufacturing Journey of Alarm Cables

The journey of manufacturing alarm cables involves a meticulous process of material selection, design optimization, and quality control. As a leading manufacturer, we emphasize precision and attention to detail at each step, from raw material procurement to final product testing. This approach guarantees that each cable we produce meets the rigorous standards required for security applications.

- The Impact of Customization in Alarm Cables: A Manufacturer's View

Customization is a key component of our manufacturing strategy for alarm cables, allowing us to meet specific customer requirements. As a manufacturer, we offer customization in aspects such as insulation type, conductor gauge, and sheath color, providing tailored solutions for diverse security scenarios. This flexibility ensures our customers receive cables that perfectly align with their installation needs.

Image Description