Product Details

| Parameter | Specification |

|---|---|

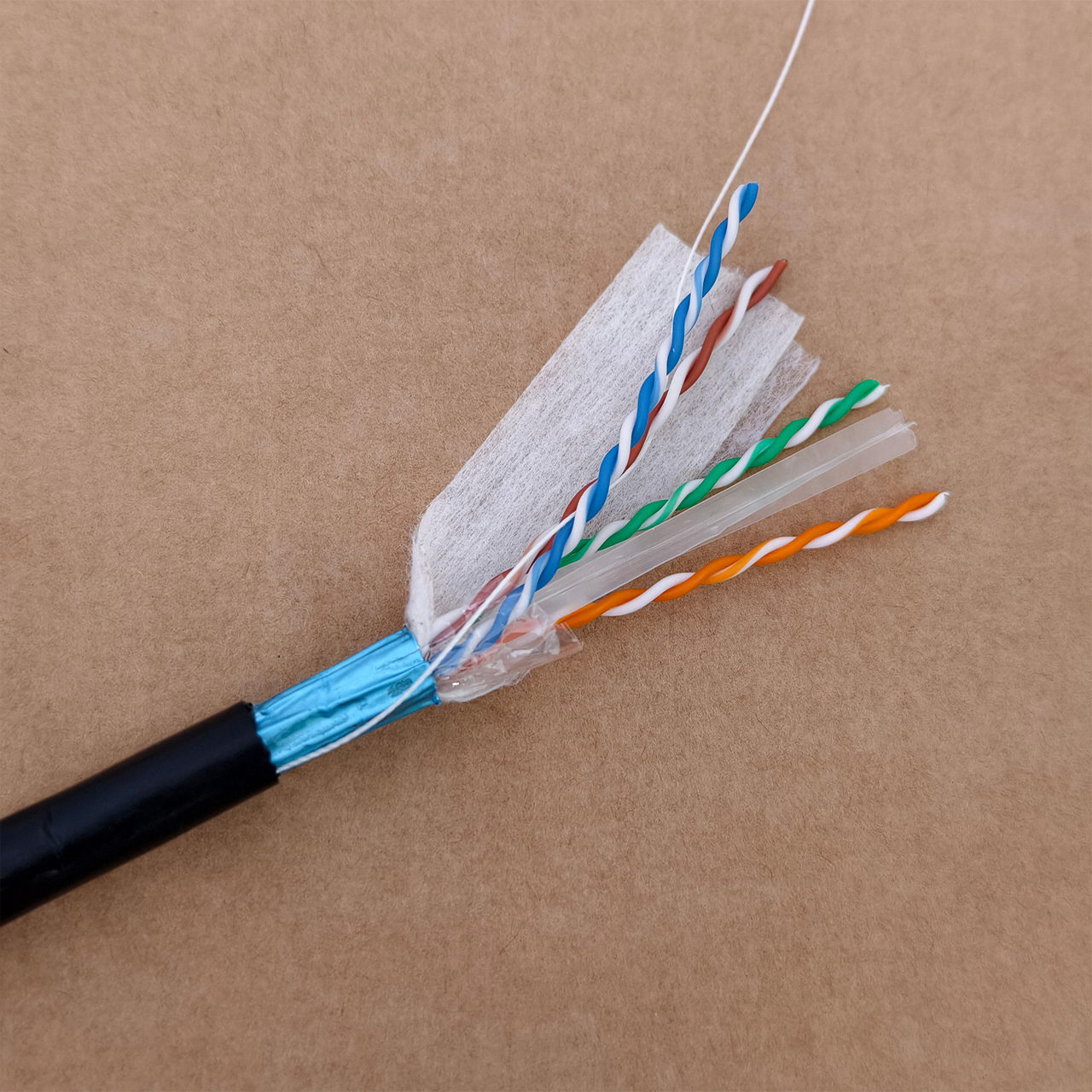

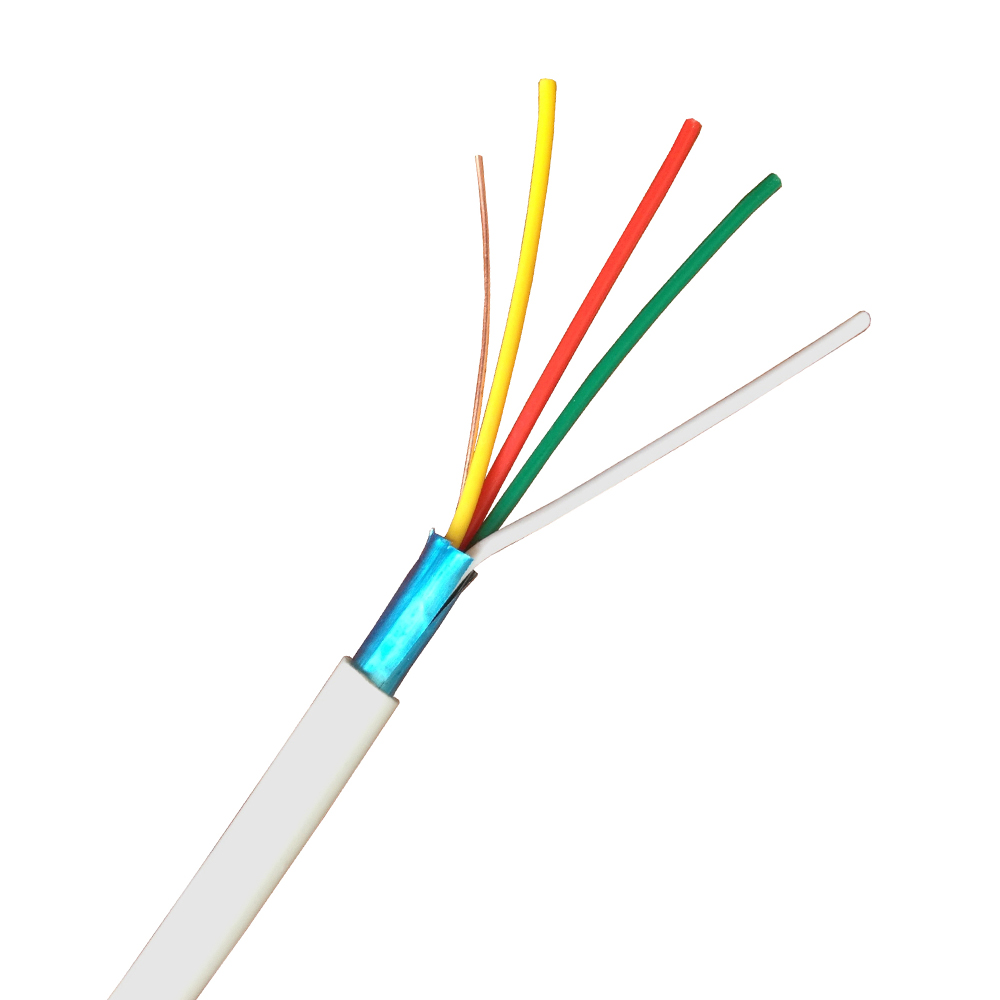

| Conductor | 23AWG Bare Copper |

| Core | 4 Pairs Stranded |

| Insulation | PE Retardant |

| Outer Jacket | PE or Double Jacket PVC&PE |

| Shielding | Water Blocking Type |

| Drain Wire | TC |

Common Product Specifications

| Feature | Description |

|---|---|

| Bandwidth | Tested up to 500 MHz |

| Ethernet Compatibility | 1 Gigabit and 5 Gigabit |

| Compliance | ANSI/TIA 568.2-D |

| Weather Resistance | Sunlight, Dirt, Snow, Moisture |

Product Manufacturing Process

Manufacturers of copper coated aluminum cables utilize advanced techniques such as electroplating or cladding to coat an aluminum core with copper. This process allows for a combination of the benefits of both materials: the conductivity of copper with the lightweight nature of aluminum. Uniformity in the copper coating is crucial to ensure consistent electrical performance, particularly in applications involving alternating current (AC) where the skin effect is prominent. The controlled manufacturing process results in a durable and cost-effective cable solution that meets various industry standards.

Product Application Scenarios

FTP CAT6 cables with copper coated aluminum are widely used by manufacturers in telecommunications, automotive, and networking industries. These cables are ideal for environments where weight reduction and cost efficiency are prioritized without compromising on performance. In outdoor scenarios, such as CCTV systems, the cables are exposed to harsh weather, requiring robust construction for UV resistance and waterproof capabilities. By integrating additional protective layers and anti-UV particles, these cables ensure long-term reliability, making them a preferred choice for demanding network infrastructure setups.

Product After-sales Service

Our manufacturer’s commitment extends beyond delivering quality copper coated aluminum cables. We provide comprehensive after-sales support including a warranty service, technical support for installation queries, and a responsive customer service team to address any product-related issues. Warranty conditions vary and depend on regional specifics and product types.

Product Transportation

Transportation of FTP CAT6 cables is managed with utmost care by our partnered manufacturers. Each unit is packed in accordance with international shipping standards to prevent damage during transit. Large quantities are shipped in bulk with special considerations for storage and handling. Delivery timelines are optimized based on geographic location and order size, ensuring timely arrival at the customer’s destination.

Product Advantages

- Cost-Effectiveness: Copper coated aluminum offers significant cost savings while retaining key conductive properties.

- Lightweight Design: Ideal for applications where weight is a concern, such as in automotive industries.

- Corrosion Resistance: The copper coating provides protective benefits for long-lasting performance.

- Versatility: Suitable for various applications like network installations and outdoor use.

Product FAQ

- What are copper coated aluminum cables?

Copper coated aluminum cables are electrical cables made using a combination of an aluminum core and a copper coating. These are favored for their cost-effectiveness and lightweight characteristics while providing sufficient conductivity for many applications. - Why choose manufacturers offering copper coated aluminum?

Choosing manufacturers that offer copper coated aluminum cables ensures high-quality production processes and materials that meet rigorous industry standards, providing reliable performance and value. - Are these cables suitable for outdoor use?

Yes, these cables are designed to withstand outdoor conditions with appropriate jackets and UV resistance components, making them ideal for installations exposed to sunlight and moisture. - How is the conductivity of copper coated aluminum cables?

Though not on par with pure copper, the copper coating provides good conductivity, especially addressing surface current flows in AC applications. - Can they replace pure copper cables?

While copper coated aluminum cables offer a great alternative for many uses, they may not completely replace pure copper, especially in high-power applications where pure copper's superior conductivity is essential. - What are the limitations of these cables?

Limitations include lower current carrying capacity and less mechanical strength compared to pure copper cables, potentially affecting their application in some scenarios. - How do manufacturers ensure quality?

Manufacturers implement stringent quality control measures throughout the production process, including testing for conductivity, coating adhesion, and durability to ensure product reliability. - What are the primary applications?

These cables are primarily used in telecommunications, automotive industries, and networking setups, offering efficient solutions where weight and cost savings are prioritized. - How does corrosion affect these cables?

The copper coating provides a degree of protection against corrosion, ensuring longevity and performance in environments where moisture is present. - Is support available for installation?

Yes, manufacturers typically offer technical support and guidance to assist customers in proper installation and maintenance of the cables.

Product Hot Topics

- The Growing Trend of Copper Coated Aluminum Cables

The rise in demand for cost-effective and lightweight cabling solutions has propelled copper coated aluminum cables into the spotlight. More manufacturers are adopting this material to balance performance and budgetary constraints, making it a hot topic in the telecommunications and construction industries. - Environmental Impact of Copper Coated Aluminum Versus Copper

The production of copper coated aluminum cables is often seen as more environmentally friendly compared to pure copper cabling. Manufacturers highlight reduced copper usage as a key benefit, contributing less to resource depletion while maintaining adequate conductivity for most applications. - Comparative Performance Analysis: Copper vs. Copper Coated Aluminum

Manufacturers have been publishing data comparing the performance of traditional copper cables and newer copper coated aluminum options. While pure copper excels in some areas, the lightweight and cost advantages of copper coated aluminum are proving compelling for many businesses. - Revolutionizing Automotive Wiring with Lightweight Materials

In the automotive industry, the shift towards lightweight materials like copper coated aluminum is transforming wiring designs. Manufacturers emphasize the importance of these materials in improving fuel efficiency and reducing vehicular weight. - The Role of Innovation in Cable Manufacturing

Innovation in manufacturing processes is crucial in enhancing the properties of copper coated aluminum cables. With advancements in electroplating and cladding technologies, manufacturers are producing cables with improved conductivity and lifespan, making them a hot topic for industry insiders. - Challenges Faced by Manufacturers in Coating Technologies

Manufacturers of copper coated aluminum cables encounter several technical challenges, including ensuring uniform copper coating and maintaining adherence. Overcoming these challenges is essential for delivering consistent and reliable products. - Adapting Copper Coated Aluminum for High-Speed Networks

As data networks demand higher speeds, manufacturers are tasked with adapting copper coated aluminum cables to meet these performance criteria. Innovations in design and materials are required to ensure these cables support next-generation networking. - Consumer Perception and Adoption Rates of New Cable Technologies

The adoption rate of copper coated aluminum cables is steadily increasing as manufacturers focus on educating consumers on the benefits and applications of these products. Transparency in performance data and direct comparisons to traditional materials help build consumer trust. - Developing Standards for Copper Coated Aluminum Use

Industry standards for copper coated aluminum cables are evolving as manufacturers and industry bodies collaborate to establish guidelines. These standards ensure quality, safety, and interoperability across applications. - The Future of Electrical Cabling Innovations

The future looks promising for copper coated aluminum cables, with manufacturers continuously researching and testing new methods to enhance performance and versatility. As technology progresses, these cables are expected to become even more integral in both consumer and industrial applications.

Image Description