Product Details

| Parameter | Details |

|---|---|

| Brand | ASTON or OEM |

| Origin | Hangzhou Zhejiang |

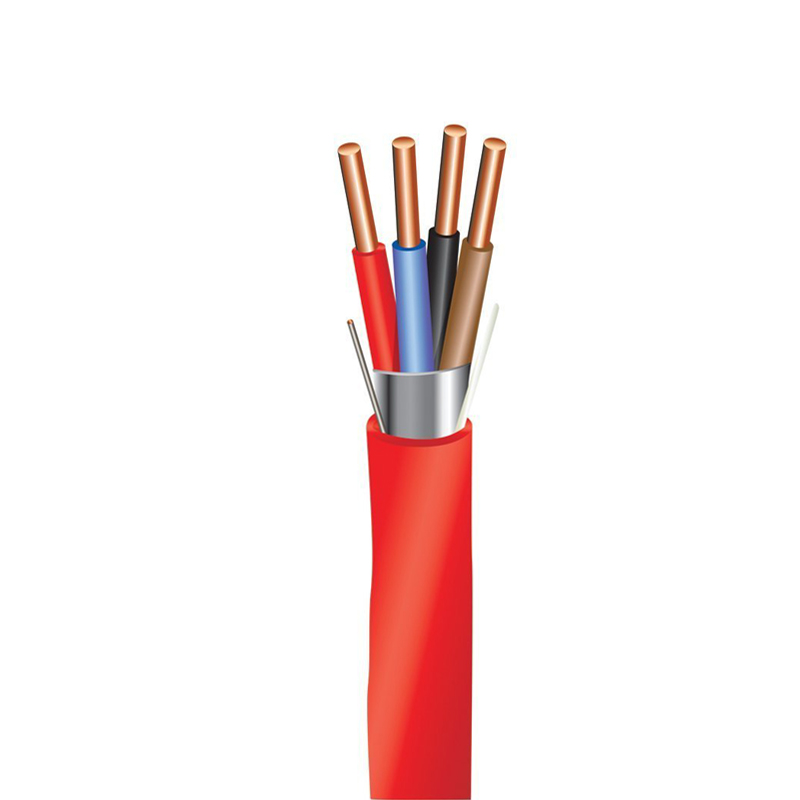

| Conductor | 18 AWG Copper |

| Insulation | Gas Injected Polyethylene |

| Jacketing | PVC, LSZH, PE |

| Color | White, Black, Customized |

| Diameter | 0.265'' Nominal |

Common Product Specifications

| Frequency | Attenuation (dB/100m) |

|---|---|

| 5 MHz | 1.7 |

| 50 MHz | 5.0 |

| 200 MHz | 8.7 |

| 400 MHz | 12.8 |

| 800 MHz | 18.0 |

| 1000 MHz | 19.8 |

| 1350 MHz | 23.8 |

| 1750 MHz | 28.0 |

| 2150 MHz | 31.4 |

| 3000 MHz | 38.0 |

Product Manufacturing Process

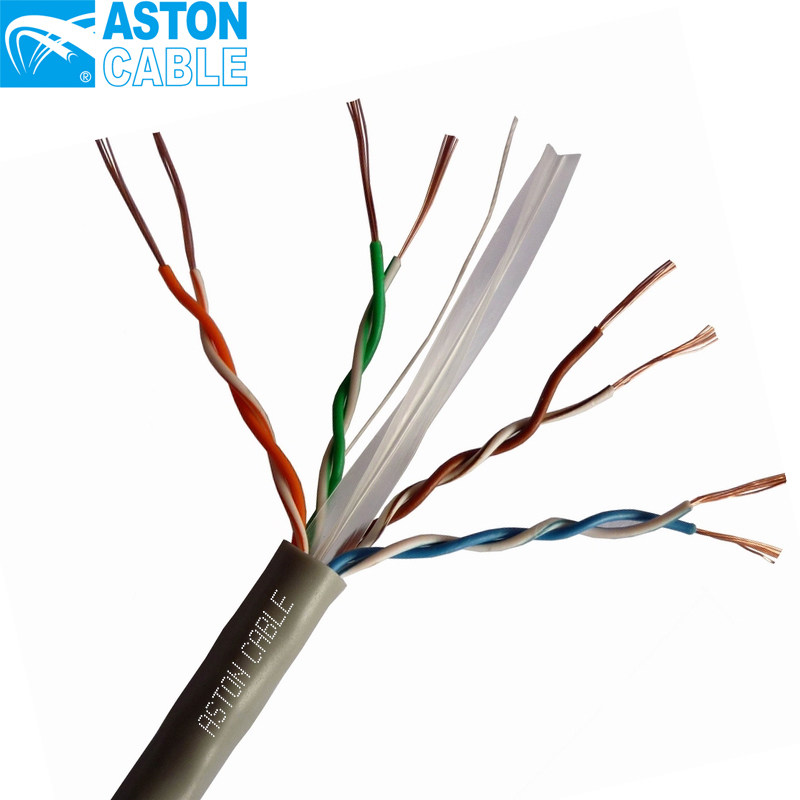

The manufacturing of coaxial cables involves a stringent quality-controlled process to ensure high standards and reliable performance. Key stages include material selection of copper for its conductivity, drawing the conductor through dies for precision diameter, applying dielectric insulation to protect against external interference, and adding a metallic shield for electromagnetic protection. Finally, the cables are jacketed with materials like PVC to safeguard against environmental factors. Quality control tests are rigorously conducted to verify electrical and physical attributes, ensuring compliance with industry standards and customer requirements. According to industry research, optimized processes and materials are pivotal for achieving superior coaxial cable performance, aiding in reduced signal loss and enhanced transmission capabilities.

Product Application Scenarios

Coaxial cables are indispensable across multiple sectors including telecommunication, broadcasting, and security systems due to their robustness and efficiency in signal transmission. They are widely utilized in television and internet services, connecting network providers to consumers with minimal signal interference. In telecommunications, coaxial cables link radio transmitters and receivers with their antennas, ensuring clear communication. In medical equipment, they facilitate reliable signal transmission in diagnostic devices. Meanwhile, in security systems, they connect CCTV cameras to monitoring units, providing uninterrupted data flow. The continued advancements in coaxial cable technologies are driving their adoption in newer applications, enhancing connectivity and system integrations globally.

Product After-Sales Service

We are committed to providing excellent after-sales service to all our customers. Our team of experts is available to assist with any concerns regarding installation, performance, or maintenance of our coaxial cables. We provide comprehensive support and guidance to ensure you achieve optimal performance from our products. Additionally, we offer a warranty that covers manufacturing defects and ensures your investment is protected. For returns or exchanges, please contact our customer service team within the stipulated period.

Product Transportation

All coaxial cables are packaged securely for transportation to prevent any damage during transit. We coordinate with reliable shipping partners to offer prompt delivery. Our packaging adheres to international shipping standards, ensuring that the products reach you in perfect condition. We provide tracking details for all shipments, so you can monitor the progress of your delivery.

Product Advantages

Our coaxial cables are designed with a 100% copper conductor that ensures superior signal transmission and longevity. They feature advanced insulation and shielding techniques that greatly reduce electromagnetic interference. The robust PVC jacket offers excellent protection against environmental factors, contributing to the cable's durability. Our cables are compliant with RoHS, CE, and IEC standards, aligning with global quality benchmarks.

Product FAQ

- What is the minimum order quantity for your coaxial cables?

- How do your cables ensure minimal signal loss?

- Are your coaxial cables suitable for outdoor use?

- Can I customize the cable color?

- What certifications do your coaxial cables have?

- Do you provide installation support?

- What is the expected lifespan of your coaxial cables?

- Are there any restrictions on cable usage?

- How are your cables packaged for delivery?

- Do you provide samples for testing purposes?

The minimum order quantity is 30 km, allowing manufacturers to fulfill large-scale requirements efficiently.

Our cables feature high-quality 100% copper conductors and advanced insulation, ensuring minimal signal attenuation even over long distances.

Yes, our cables are available with UV-resistant PVC jacketing, making them ideal for both indoor and outdoor installations.

Yes, we offer customization options for cable color, including standard white, black, and bespoke colors to match specific requirements.

Our cables are certified with RoHS, CE, and ISO9001, ensuring they meet international safety and quality standards.

Yes, we offer comprehensive installation instructions and support to ensure seamless setup and optimal performance of our products.

Designed with robust materials and construction, our coaxial cables offer a long service life, typically exceeding industry standards for durability.

Our cables are versatile and can be used across various applications. However, it is essential to choose the right specifications to match the intended use.

Our cables are securely packaged in line with international shipping best practices to protect them against potential transit damage.

Yes, we offer samples to manufacturers who wish to assess the quality and performance of our coaxial cables before placing a bulk order.

Product Hot Topics

- How coaxial cable manufacturers are innovating in signal transmission

- The role of coaxial cable manufacturers in telecommunications

- Choosing the right coaxial cable from leading manufacturers

- Impact of coaxial cables in modern broadcasting systems

- Quality control practices by coaxial cable manufacturers

- Future trends in coaxial cable technologies

- Sustainable practices by leading coaxial cable manufacturers

- Adapting coaxial cables for smart home technologies

- The significance of RoHS and CE certifications for coaxial cables

- Comparing coaxial cable manufacturers for industrial applications

Leading coaxial cable manufacturers are continually innovating processes to enhance signal transmission efficiency. By employing advanced materials such as high-purity copper and sophisticated insulation techniques, manufacturers are significantly reducing signal loss and improving bandwidth capabilities. These innovations are crucial in meeting the rising demand for high-speed internet connectivity and reliable telecommunications infrastructure. With ongoing research and development, we can expect even greater advancements in coaxial cable technologies, ensuring robust communication networks for the future.

Coaxial cable manufacturers play an integral role in the telecommunications industry by providing essential components that facilitate data transmission. Their expertise in producing high-quality cables ensures that telecommunication networks can deliver clear, uninterrupted signals, which is vital for maintaining connectivity in our increasingly digitized world. As the demand for higher bandwidth and faster internet speeds grows, manufacturers are continuously developing solutions that cater to these needs, thus driving progress in global communication infrastructures.

Selecting the appropriate coaxial cable from reliable manufacturers involves assessing various factors such as conductor material, insulation type, and jacket robustness. Leading manufacturers like ASTON provide detailed specifications and guidance to help consumers make informed decisions. By understanding the application needs and environmental conditions, consumers can choose the right coaxial cable that offers optimal performance and longevity, ensuring value for their investment.

Coaxial cables are pivotal in modern broadcasting systems, providing the necessary infrastructure for transmitting high-definition audio and video signals with minimal interference. Leading manufacturers have developed cables that support the increased data rates required for high-quality broadcast content. As the broadcasting industry evolves to meet consumer demands for better quality media, coaxial cable manufacturers are at the forefront, supplying the technology that powers this transformation.

Quality control is a cornerstone of coaxial cable manufacturing, ensuring products meet strict industry standards for performance and reliability. Leading manufacturers rigorously test cables for electrical properties like impedance and attenuation and verify physical attributes such as tensile strength. These practices guarantee that the cables perform optimally in various applications, from telecommunication to broadcasting, maintaining the manufacturer's reputation for excellence.

The future of coaxial cable technology looks promising as manufacturers continue to innovate in materials and design to meet the growing demand for high-speed data transmission. Future trends include the integration of hybrid solutions combining fiber optics and coaxial technology, maximizing both technologies' strengths. Manufacturers are key players in this evolution, advancing cable performance to ensure they remain relevant in modern communication infrastructures.

As environmental concerns become more pertinent, leading coaxial cable manufacturers are adopting sustainable practices in their production processes. This includes using recyclable materials, minimizing waste, and implementing energy-efficient manufacturing techniques. These initiatives not only reduce the environmental impact but also align with global efforts towards sustainable development, ensuring manufacturers remain responsible and competitive in the market.

With the rise of smart home technologies, coaxial cable manufacturers are adapting their products to support seamless integration with smart systems. The advanced signal transmission capabilities of coaxial cables make them ideal for connecting various smart devices, ensuring efficient communication and control. As smart homes become more prevalent, manufacturers are at the forefront, developing solutions that enhance interconnectivity and user experience.

RoHS and CE certifications are crucial indicators of quality and safety for coaxial cables. They assure consumers that the products meet strict European standards for environmental and safety compliance. For manufacturers, achieving these certifications signifies a commitment to producing reliable, high-quality cables that adhere to international regulations. Consumers can trust that certified coaxial cables are safe for use and meet their performance expectations.

When selecting coaxial cable manufacturers for industrial applications, it's essential to compare their product offerings based on durability, signal performance, and compliance with industry standards. Distinguished manufacturers like ASTON provide comprehensive details and technical support, aiding consumers in making informed choices. Evaluating manufacturers on these criteria helps ensure that the chosen cables perform effectively in demanding industrial environments.

Image Description