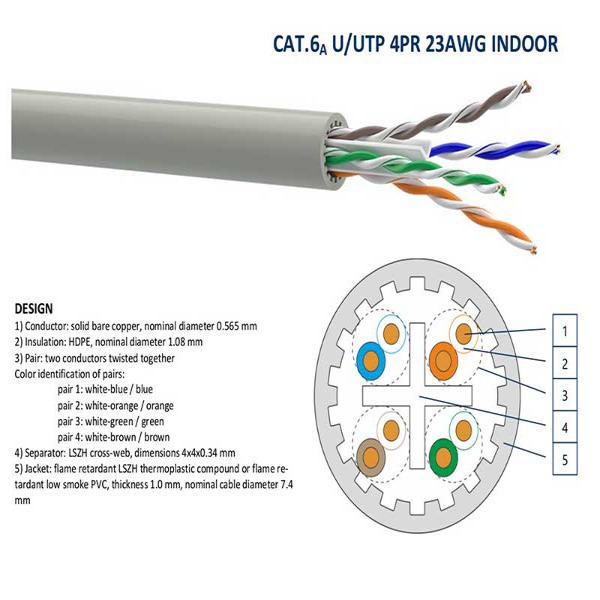

Product Main Parameters

| Parameter | Details |

|---|---|

| Conductor | 23AWG Bare Copper |

| Insulation | PE |

| Shielding | 4 pairs aluminum foil shield |

| Outer Jacket | PVC/LSZH |

| Color | Customized |

| Standard | CE, RoHS, ISO9001 |

Common Product Specifications

| Specification | Description |

|---|---|

| Test Frequency | 500MHz |

| Data Rate | 10Gbps |

| Length | Customizable |

| MOQ | 200 Rolls |

| Port | Ningbo |

Product Manufacturing Process

The manufacturing process of shielded control cables begins with the selection of high-quality copper for the conductors. These conductors are then insulated with polyethylene to ensure durability and prevent shorts. The crucial step in producing shielded cables is the application of the shielding materials. Depending on the requirement, manufacturers use either foil or braided shielding to protect against electromagnetic interference. The final step involves applying the outer jacket, typically made from PVC or LSZH, which provides additional protection against environmental factors. Rigorous testing is conducted at each stage to ensure compliance with international standards, confirming the cable's performance and reliability.

As detailed in studies on cable shielding effectiveness, the manufacturing process is critical to achieving optimal performance, particularly in environments prone to high electromagnetic interference. The integration of quality materials and precise engineering practices ensures that these cables meet stringent industry specifications, offering exceptional noise reduction and signal integrity.

Product Application Scenarios

Shielded control cables are vital in numerous sectors. In industrial automation, these cables facilitate smooth operations by minimizing interference, ensuring that control signals remain uncorrupted. In the medical field, where accuracy is paramount, shielded cables help prevent data errors in life-supporting equipment. The audiovisual industry uses these cables to maintain sound and video quality by reducing hum and buzz from nearby electronics. The telecommunications industry benefits from shielded control cables in maintaining data integrity over long distances, crucial for high-speed internet and reliable communication networks. Research has shown that the choice of cable can significantly impact operational efficiency and safety in these applications.

These application scenarios highlight the cable's role in providing robust solutions for environments where precision and reliability are non-negotiable. By employing shielded control cables, manufacturers can enhance the performance and safety of their systems, safeguarding against potential disruptions caused by electromagnetic interference.

Product After-Sales Service

Our commitment to quality extends beyond manufacturing. We offer comprehensive after-sales support, including technical assistance and product replacement for any manufacturing defects. We are dedicated to ensuring customer satisfaction and maintaining the long-term reliability of our shielded control cables.

Product Transportation

Shielded control cables are packaged securely to prevent damage during transit. They are shipped using reliable freight services from our facility to the designated port, ensuring timely delivery. We provide tracking information so clients can monitor the progress of their shipments.

Product Advantages

- Noise Reduction: Minimizes electromagnetic interference, ensuring clean signal transmission.

- Signal Integrity: Maintains stable signal quality, essential for sensitive data and communication applications.

- Durability: Robust construction resists physical and environmental damage, extending the cable's lifespan.

- Safety: Prevents emission of interference that could affect other systems.

Product FAQ

- What is the primary use of shielded control cables?

Shielded control cables are used to protect signal integrity from electromagnetic and radio-frequency interference, ensuring reliable operation of electronic circuits in various applications, such as industrial automation and data transmission.

- How do manufacturers ensure the quality of shielded control cables?

Manufacturers employ advanced machinery and rigorous quality control measures to produce shielded control cables. Regular testing against international standards ensures consistent quality and performance.

- Are all shielded cables the same?

No, shielded cables differ based on their shielding methods (foil, braided, or spiral) and materials used for conductors and outer jackets. These differences impact their performance in various applications.

- What is the significance of the cable's outer jacket?

The outer jacket, usually made of durable polymers like PVC or LSZH, provides protection against physical damage and environmental factors, enhancing the cable's durability and lifespan.

- How do shielded control cables improve safety?

Besides preventing external interference, shielded control cables help contain internal interference, reducing the possibility of affecting other systems within the vicinity, thus improving the overall safety of electrical installations.

- Do shielded cables require special installation considerations?

Yes, proper grounding is essential for the shielding to be effective. This requires careful planning during installation to ensure optimal performance of the cable in its specified application.

- What factors contribute to the higher cost of shielded cables?

The use of additional materials for shielding and the intricate manufacturing processes involved contribute to the higher cost of shielded control cables compared to unshielded varieties.

- Can shielded cables be customized?

Yes, manufacturers often offer customization options for shielded control cables, including specifications on length, color, and materials to meet specific application requirements.

- What are the environmental considerations for shielded control cables?

Manufacturers aim to use environmentally friendly materials and practices, ensuring that shielded control cables comply with regulations like RoHS, minimizing their impact on the environment.

- How do manufacturers address flexibility in shielded cables?

Although shielding can reduce flexibility, manufacturers design cables with specific applications in mind, optimizing materials and construction to accommodate necessary bends and movements without compromising performance.

Product Hot Topics

- Industrial Use of Shielded Control Cables

Manufacturers emphasize the robustness of shielded control cables in industrial settings, where these cables are indispensable in maintaining signal integrity amidst machinery and power lines. These cables' design mitigates electromagnetic interference effectively, ensuring that production processes and automation systems operate seamlessly without downtime. By choosing high-quality shielded control cables, industries can enhance their operational reliability and efficiency.

- Importance of Shielded Control Cables in Medical Devices

In healthcare environments, shielded control cables are pivotal in ensuring the accurate functioning of medical devices. With the proliferation of electronic systems in hospitals, these cables help prevent interference that could lead to erroneous readings or equipment failures. Manufacturers focus on producing high-standard cables that meet stringent health and safety regulations, providing peace of mind to healthcare providers and patients alike.

- Audio/Visual Systems and Shielded Control Cables

For audio/visual systems, maintaining signal quality is crucial. Manufacturers of shielded control cables offer solutions that minimize hum and interference, allowing consumers to enjoy optimal sound and image clarity. This is particularly important in professional settings such as studios and conference centers, where sound and video quality can significantly affect communication and entertainment experiences.

- Data Transmission Efficiency with Shielded Control Cables

High-speed data transmission is essential in today's interconnected world. Manufacturers provide shielded control cables specifically designed for telecommunications, ensuring data integrity across long distances. This is vital for businesses and service providers looking to maintain robust and reliable networks, as even minor disruptions can lead to significant downtime and financial losses.

- Sustainability and Shielded Control Cables

Sustainability is a growing focus for manufacturers of shielded control cables, who are implementing eco-friendly materials and energy-efficient production methods. These efforts align with global environmental goals, ensuring that cable production and disposal have minimal impact on the environment while meeting performance standards required by modern technology.

- Innovation in Shielded Control Cable Design

The field of shielded control cables is seeing continuous innovation, with manufacturers developing new materials and techniques to enhance cable performance and durability. This is crucial in keeping up with the ever-evolving demands of technology, allowing for better noise reduction and increased data capacities, thereby supporting the infrastructure of future digital landscapes.

- Cost vs. Benefit Analysis of Shielded Control Cables

Manufacturers often address the cost implications of shielded control cables, highlighting the long-term benefits. Despite higher initial costs, these cables offer superior performance and longevity, minimizing maintenance and replacement expenses. For many users, the investment in shielded cables results in overall cost savings by preventing data loss and system failures.

- Regulatory Compliance of Shielded Control Cables

Compliance with industry standards is a key consideration for manufacturers of shielded control cables. Adhering to certifications such as IEC, CE, and RoHS is essential for ensuring product safety and quality. These standards also facilitate global trade, providing manufacturers with access to wider markets and ensuring that their products are accepted internationally.

- Customization Options for Shielded Control Cables

Manufacturers offer numerous customization options to meet diverse client requirements for shielded control cables. These options allow for variations in cable length, conductor materials, and shielding types, catering to specific applications. Customization enhances the adaptability of cables to unique operational environments, ensuring they meet precise functional and aesthetic criteria.

- Future Trends in Shielded Control Cable Technology

The future of shielded control cables looks promising, with manufacturers exploring advanced materials and smart technologies. Integrated sensors for real-time monitoring and the use of artificial intelligence for predictive maintenance are potential innovations. These advancements could revolutionize cable applications, enhancing their functionality and efficiency in an increasingly digital world.

Image Description