Product Main Parameters

| Parameter | Details |

|---|---|

| Center Conductor | 0.81mm 20AWG CCS |

| Shielding | 95% AL/CCA Braiding |

| Jacket Material | PVC, LSZH, PE |

| Operating Frequency | Up to 3 GHz |

| Impedance | 75 Ohms |

Common Product Specifications

| Specification | Details |

|---|---|

| MOQ | 30KM |

| Weight | 5.2KG/100m |

| Color | Customized |

| Connector | BNCDC |

| Origin | Hangzhou Zhejiang, China |

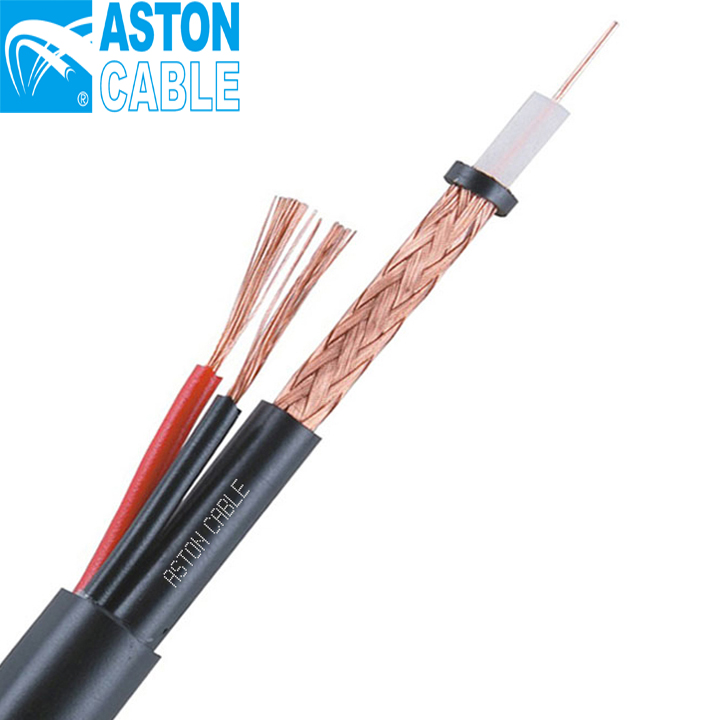

Product Manufacturing Process

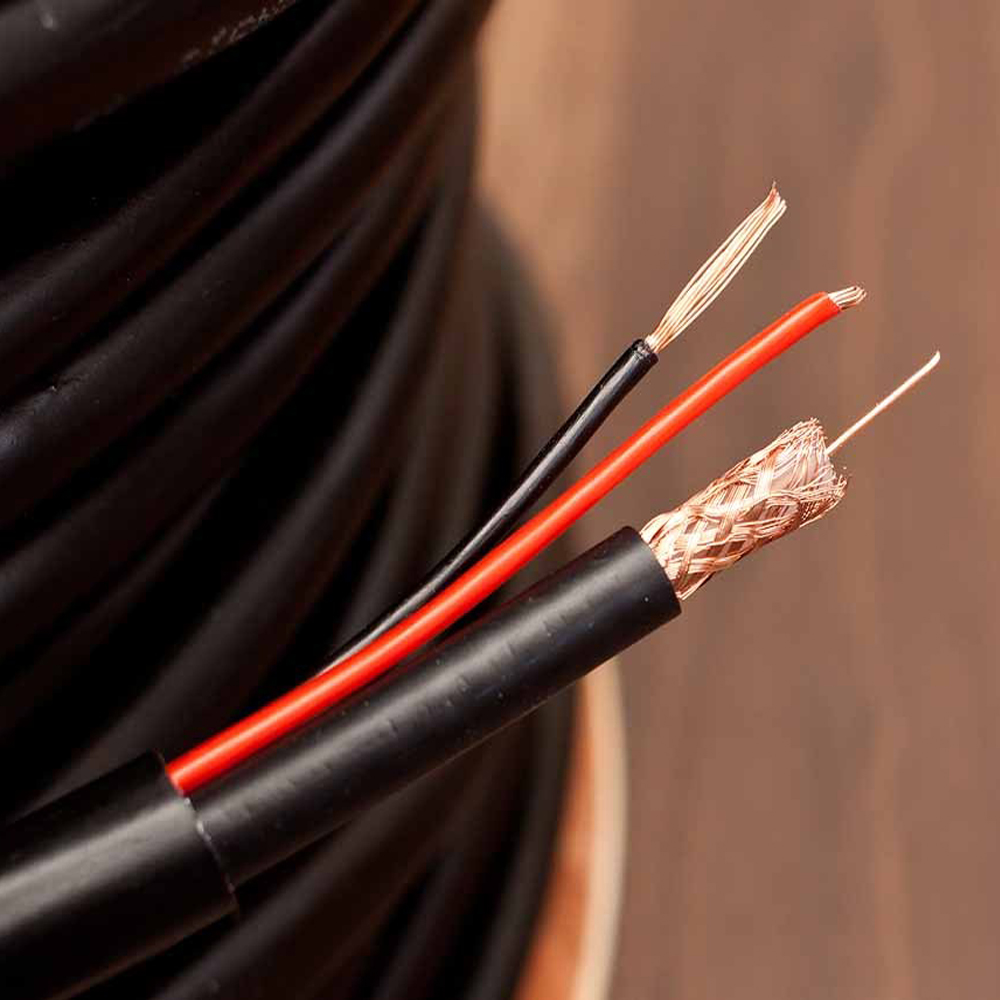

Manufacturing RG59 shotgun cables involves several precise steps to ensure optimal quality and performance. The process begins with the selection of high-grade copper or copper-clad steel for the center conductor. The conductor is meticulously coated with dielectric insulation to maintain signal integrity by preventing leakage. Next, the insulated conductor undergoes a shielding process where aluminum or copper braiding is applied, offering protection against electromagnetic interference. This is crucial for maintaining signal clarity. The final step is the application of the outer jacket, typically made from durable PVC or PE, which provides physical protection and environmental resistance.

Product Application Scenarios

RG59 shotgun cables are predominantly used in CCTV systems, offering an efficient means of transmitting both video and power signals through a single cable run. This capability is particularly valuable in surveillance systems where cameras are located at varying distances from the central monitoring unit. Additionally, these cables are suitable for other low-frequency applications, such as video conferencing setups and certain audio-visual connections. Given their dual-function design, RG59 cables significantly reduce installation complexity and costs, making them an economical choice for large-scale surveillance projects.

Product After-Sales Service

- Complimentary technical support via live chat or telephone

- Warranty service covering manufacturing defects for up to two years

- Return and replacement options within 30 days of purchase

- Dedicated team for troubleshooting installation issues

- Online resources including manuals and installation guides

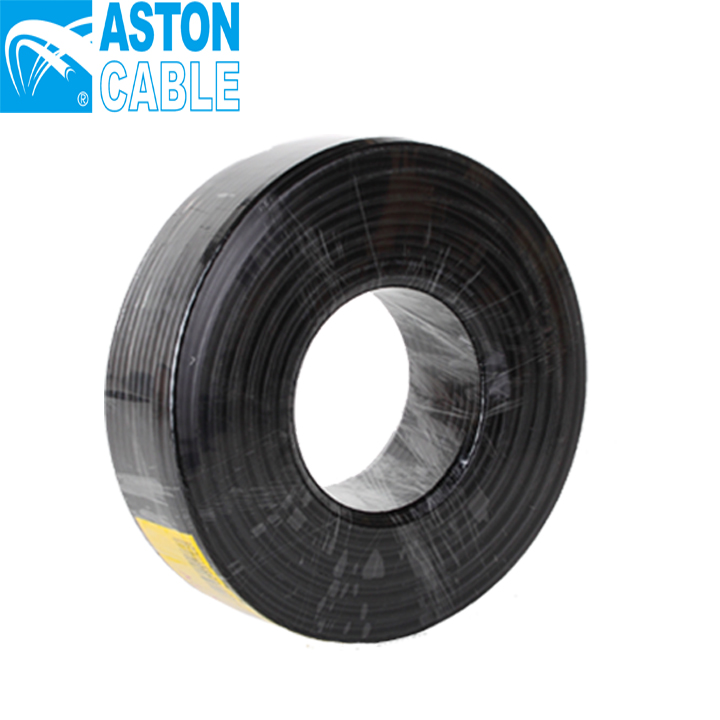

Product Transportation

Our RG59 shotgun cables are packaged meticulously to ensure safe transportation, using standard export packaging methods. Each coil is shrink-wrapped and boxed to prevent damage during transit. Orders are dispatched from Ningbo port, China, with tracking services available for customer convenience. Delivery times vary depending on destination but are typically within 15-30 days for international shipments.

Product Advantages

- Integrated video and power transmission simplifies installations

- Cost-effective solution for surveillance systems

- Durable construction ensures longevity and resistance to environmental factors

- Flexible design allows for easy routing in confined spaces

- Manufactured in China with strict quality controls

Product FAQ

- What is the maximum run length for the RG59 shotgun cable?

Typically, the maximum run length for RG59 cables is 750 feet without signal degradation, although this can vary based on installation conditions and power requirements.

- Can this cable be used for outdoor installations in China?

Yes, the RG59 shotgun cable comes with a PE jacket option for outdoor use, providing resistance against moisture and UV rays.

- Is the RG59 shotgun cable compatible with all CCTV systems?

Our RG59 shotgun cable is designed to be compatible with most standard CCTV systems, providing reliable video and power transmission.

- Does the cable support both video and audio signals?

The primary use of the RG59 cable is for video and power; however, modifications can allow audio transmission depending on system specifications.

- What are the color options for the jackets?

The cable's jacket color can be customized based on project requirements, with common colors being black, white, and grey.

- How is the cable packaged for shipping?

The cables are packaged using coil reels or drums, with additional protection in carton boxes to prevent damage during transit.

- Does the cable meet the CE and RoHS standards?

Yes, our RG59 shotgun cables are compliant with CE, RoHS, and other international standards, ensuring safety and environmental protection.

- What payment methods are accepted for international orders?

We accept wire transfer, credit card payments, and other secure payment methods suitable for international transactions.

- Is the cable suitable for high-frequency digital signals?

RG59 shotgun cables are best for low-frequency analog signals; for high-frequency digital needs, RG6 cables are recommended.

- Are bulk orders eligible for discounts?

Yes, we offer competitive pricing and discounts for bulk orders, especially for large surveillance projects.

Product Hot Topics

- Best Practices for Installing RG59 Shotgun Cables in China

To ensure optimal performance when installing RG59 shotgun cables, it's essential to follow best practices. Proper grounding is crucial to prevent electromagnetic interference. Additionally, using quality connectors and ensuring the cables are not exposed to excessive tension or sharp bends can improve longevity and signal quality. Choosing the right jacket material, such as PE for outdoor installations, helps protect the cables from environmental damage.

- The Growing Demand for RG59 Shotgun Cables in CCTV Systems

With the rise of surveillance and security concerns globally, including in China, the demand for reliable cabling systems like the RG59 shotgun cable has increased. These cables offer a seamless solution for transmitting both video and power, simplifying installations and reducing costs. The versatility and efficiency of RG59 cables make them a popular choice among installers and security system designers.

- Advantages of Using China-Made RG59 Shotgun Cables

China has established itself as a leader in the manufacturing of high-quality cabling solutions, including RG59 shotgun cables. The advantages of choosing China-made cables include access to cutting-edge technology, strict quality controls, and competitive pricing. These factors contribute to the global reputation of Chinese manufacturers as providers of reliable and efficient products for various applications.

- Technical Innovations in RG59 Shotgun Cable Design

Recent advancements in cable technology have seen significant improvements in the design and functionality of RG59 shotgun cables. Improved materials for center conductors, as well as enhanced shielding techniques, have resulted in cables that offer lower attenuation and increased protection against interference. These innovations ensure that RG59 cables remain a staple in security and surveillance installations worldwide.

- Comparing RG59 with RG6: Choosing the Right Cable for Your Needs

When deciding between RG59 and RG6 cables, it's important to consider the specific requirements of your project. RG59 cables are ideal for short-run, low-frequency applications, while RG6 cables are better suited for long-distance and high-frequency needs. Understanding the differences in attenuation rates, shielding, and conductor size can help you make an informed decision.

- The Environmental Impact of RG59 Cable Production

Producing RG59 cables involves the use of various materials, some of which may have environmental implications if not managed properly. Manufacturers in China are increasingly adopting sustainable practices, such as recycling and reducing emissions, to minimize the environmental impact. Consumers are encouraged to choose cables from companies that prioritize sustainability and compliance with environmental regulations.

- Future Trends in Security Cable Technology

As technology continues to evolve, the security cable industry is poised to see exciting developments. The integration of smart technology, enhanced data transmission capabilities, and eco-friendly materials are just a few trends expected to shape the future. RG59 shotgun cables will continue to adapt, offering even greater efficiencies for security and data transmission solutions.

- Customized Solutions: Tailoring RG59 Cables to Specific Project Needs

Many projects present unique challenges that require customized cabling solutions. Manufacturers offer options such as color coding, specific jacket materials, and tailored lengths to meet these needs. By working closely with suppliers, customers can ensure that their RG59 shotgun cables provide optimal performance for their specific installations.

- Quality Assurance in RG59 Cable Production

Ensuring that RG59 cables meet high standards of quality is essential for reliable performance. Quality assurance processes in manufacturing include rigorous testing for impedance, attenuation, and shielding effectiveness. Adherence to standards like CE and RoHS further guarantees that the cables will meet the required safety and performance metrics.

- Navigating International Regulations for Cable Import and Export

For businesses dealing with the international trade of RG59 cables, understanding and complying with various regulations is crucial. This includes adhering to import/export standards, customs procedures, and compliance with certifications such as CE and RoHS. Staying informed of regulatory changes can prevent delays and ensure a smooth transaction process.

Image Description