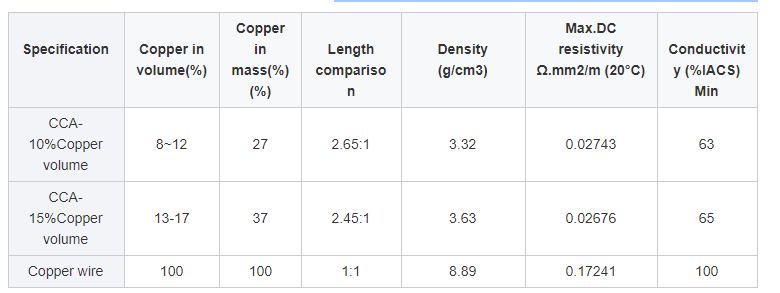

Product Main Parameters

| Parameter | Details |

|---|---|

| Material | Copper-clad Aluminum |

| Size Range | 0.12mm to 3.0mm |

| Color | Copper color |

| Daily Output | 200KM |

| MOQ | 1000KG |

Common Product Specifications

| Specification | Value |

|---|---|

| Conductor | Aluminum Core, Copper Clad |

| Certification | SGS, CE, ROHS, ISO9001 |

Product Manufacturing Process

Copper-clad aluminum wires are manufactured through a precise metallurgical bonding process where an aluminum core is tightly clad with a copper layer. This process involves the continuous extrusion of aluminum to form the core, followed by the application of copper using electroplating or extrusion techniques. The metallurgical bond ensures improved conductivity and prevents separation of materials during use. Studies have shown that this combination effectively balances cost and electrical performance, making it suitable for multiple industrial applications. Rigorous testing and quality control procedures such as tensile strength verification and conductivity assessments ensure compliance with industry standards, as highlighted in several authoritative studies.

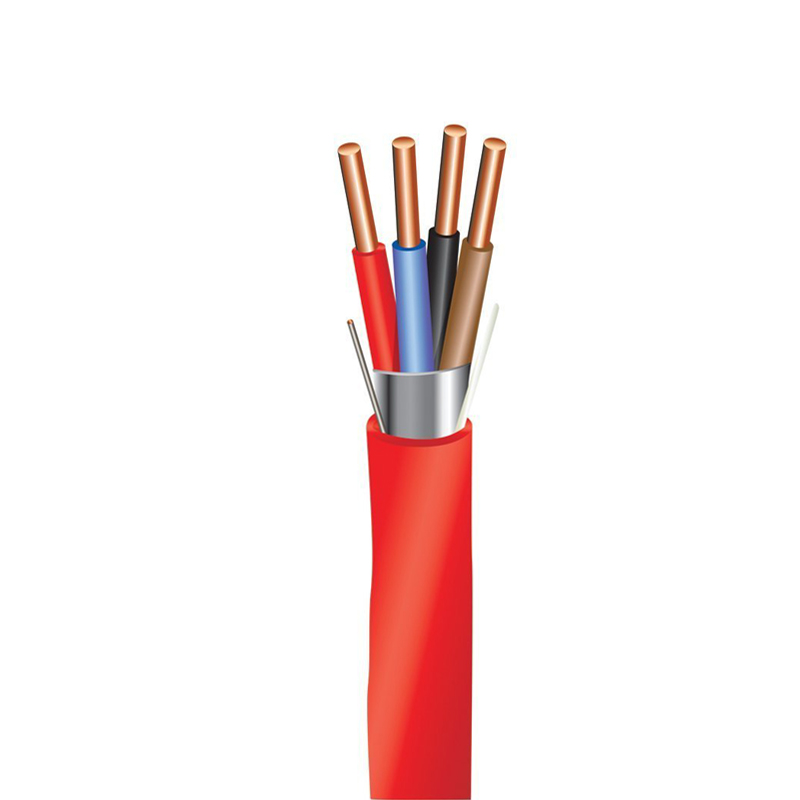

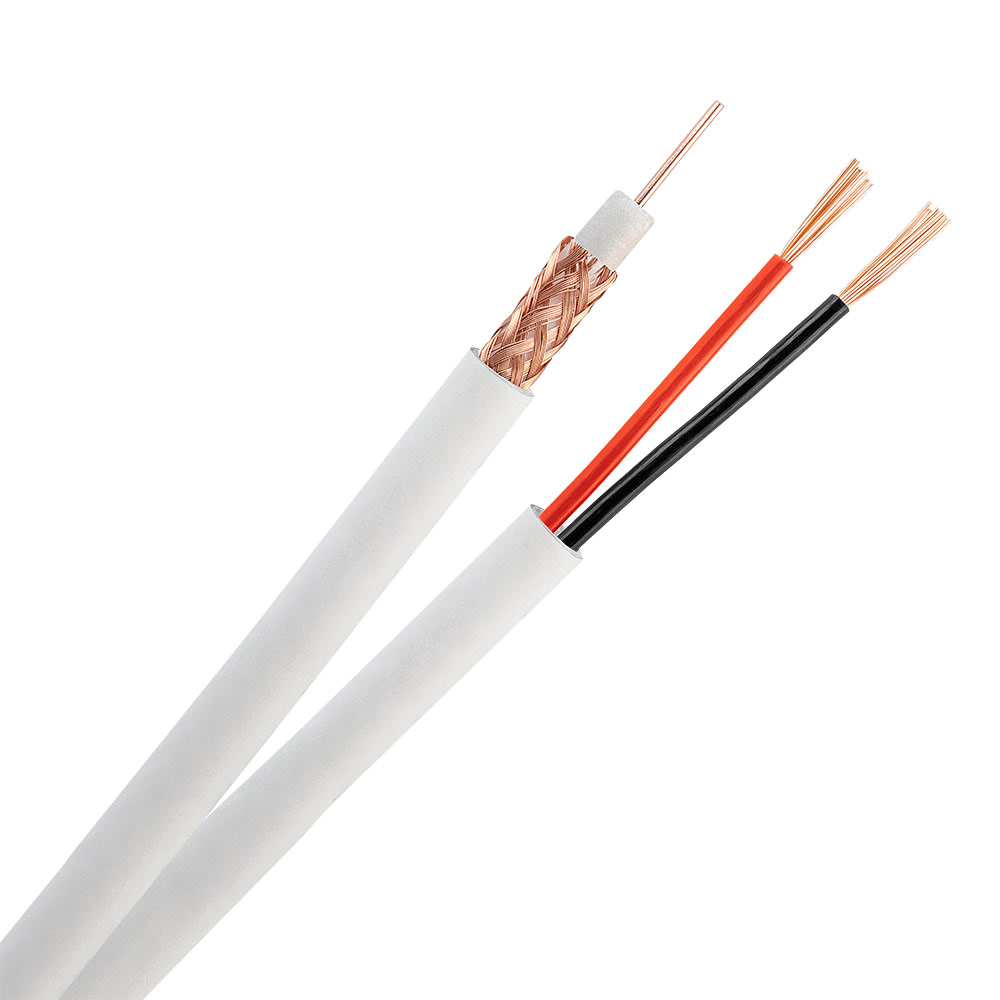

Product Application Scenarios

Copper-clad aluminum wires are extensively utilized across various industries due to their advantageous properties. In telecommunications, they are a preferred choice for coaxial cables and network wiring, offering a blend of performance and cost-effectiveness essential for large-scale data transmission. The automotive and aerospace sectors benefit from the substantial weight reduction, contributing to improved fuel efficiency and payload optimization. Analyzed in research publications, CCA wires are increasingly employed in residential and industrial electrical wiring for their balance of durability and cost savings, despite their lower conductivity compared to pure copper. These applications underscore the critical role of copper-clad aluminum in modern engineering solutions.

Product After-sales Service

At Aston Cable, customer satisfaction is paramount. We provide comprehensive after-sales support, including technical assistance, warranty services, and product replacement for defective items. Our dedicated team is available to address inquiries and ensure that all product-related concerns are resolved promptly, reflecting our commitment to quality and service excellence.

Product Transportation

Products are shipped using reliable logistics partners to ensure timely delivery. Each shipment is meticulously packed in compliance with international export standards, using protective materials to prevent damage during transit. We offer flexible shipping options from our manufacturing facility in Hangzhou, Zhejiang, through the Ningbo port, allowing us to efficiently meet the demands of global customers.

Product Advantages

- Cost-Effective: Economical alternative to pure copper.

- Lightweight: Reduces overall weight in applications.

- Corrosion Resistant: Enhanced durability in various environments.

- Versatile: Suitable for numerous industrial uses.

Product FAQ

- Q: What are the main applications of copper clad aluminum wires?

A: CCA wires are predominantly used in telecommunications, automotive, and aerospace industries. They are integral in coaxial cable manufacturing, power distribution, and weight-sensitive applications where cost-effectiveness is critical. - Q: How does the conductivity of CCA wires compare to pure copper?

A: While CCA wires are not as conductive as pure copper, they provide sufficient conductivity for many applications, combined with the advantage of reduced weight and cost. - Q: Are CCA wires suitable for outdoor use?

A: Yes, CCA wires can be used outdoors. The copper cladding offers significant resistance to corrosion, making them durable for outdoor applications. - Q: What certifications do Aston Cable's CCA wires have?

A: Our CCA wires are certified with SGS, CE, ROHS, and ISO9001, ensuring compliance with international standards for quality and safety. - Q: Can CCA wires handle high frequencies in data transmission?

A: Yes, CCA wires are suitable for high-frequency applications like CATV and radio frequency communication due to their balanced conductivity and durability. - Q: What are the packaging options available for CCA wires?

A: The wires are packaged in protective plastic drums, ensuring safety during transportation and ease of handling for installation. - Q: How does the weight of CCA wires benefit automotive and aerospace sectors?

A: CCA wires are lighter than pure copper, facilitating weight savings in vehicles and aircraft, which improves fuel efficiency and performance. - Q: Can CCA wires replace traditional copper wires in all applications?

A: While CCA wires are versatile, they may not match the conductivity of copper in applications demanding maximum electrical performance. Each use case should be evaluated for suitability. - Q: How do Aston Cable ensure quality in CCA wire production?

A: We employ advanced machinery and rigorous quality control measures, including regular testing of tensile strength and electrical conductivity, to maintain high standards. - Q: What is the lead time for CCA wire orders?

A: Lead time depends on order size and specifications. Typically, we maintain a flexible production schedule to accommodate varying customer requirements efficiently.

Product Hot Topics

- The Evolution of Copper Clad Aluminum Wires

The demand for copper clad aluminum wires has surged over the years due to their ability to balance performance with cost efficiency. These wires have evolved significantly, with technological advancements enhancing their bonding processes for improved conductivity and durability. Leading manufacturers like Aston Cable are at the forefront, continuously innovating to meet industry needs. With their growing application in critical sectors like telecommunications and aerospace, CCA wires are proving indispensable. The ongoing research into optimizing their properties further solidifies their place in modern engineering solutions, demonstrating their increasing significance in global markets.

- Why Industries Prefer Copper Clad Aluminum Wires

The preference for copper clad aluminum wires in industrial applications is largely driven by their unique properties and economic advantages. Offering a substantial weight reduction without significantly compromising on conductivity makes them ideal for industries where weight is a critical concern, such as aerospace and automotive. Manufacturers are also attracted to their cost-effectiveness and resistance to corrosion, making them a sustainable choice in long-term projects. The ability of CCA wires to provide a reliable and affordable alternative to solid copper has established them as a staple in the manufacturing of data transmission and power cables worldwide.

- Challenges in Using Copper Clad Aluminum Wires and Solutions

While the benefits of copper clad aluminum wires are numerous, challenges such as lower electrical performance compared to pure copper and issues with mechanical flexibility remain. Manufacturers are addressing these challenges by improving the cladding process to enhance conductivity and investing in research to increase the wire’s flexibility and compatibility with existing connectors. The industry's commitment to overcoming these obstacles ensures that CCA wires remain a viable option across diverse applications. Through continuous innovation and adaptation, manufacturers like Aston Cable maintain their reputation for quality and reliability.

- Impact of CCA Wires on the Telecommunications Sector

In the fast-paced telecommunications industry, where efficiency and cost are paramount, copper clad aluminum wires have become a go-to solution. Their light weight and satisfactory conductivity levels make them ideal for extensive cabling needs in large-scale communication networks. Manufacturers have embraced CCA wires for the deployment of coaxial and LAN cables, catering to the rising demand for broadband services. The adaptation of these wires underscores the telecommunications sector's pursuit of cost-effective solutions without sacrificing performance, positioning them as an indispensable component in modern network infrastructure.

- Future of Copper Clad Aluminum Wire Manufacturing

The future of copper clad aluminum wire manufacturing looks promising with continuous advancements in technology and materials science. As manufacturers strive for greater efficiency, innovations in the production process are expected to enhance the properties of CCA wires, potentially closing the gap in performance with traditional copper wiring. The increasing emphasis on sustainable and cost-effective materials will likely propel CCA wires into new markets and applications. Companies like Aston Cable are well-positioned to lead this evolution, leveraging their expertise and commitment to quality to drive the future growth of this sector.

Image Description