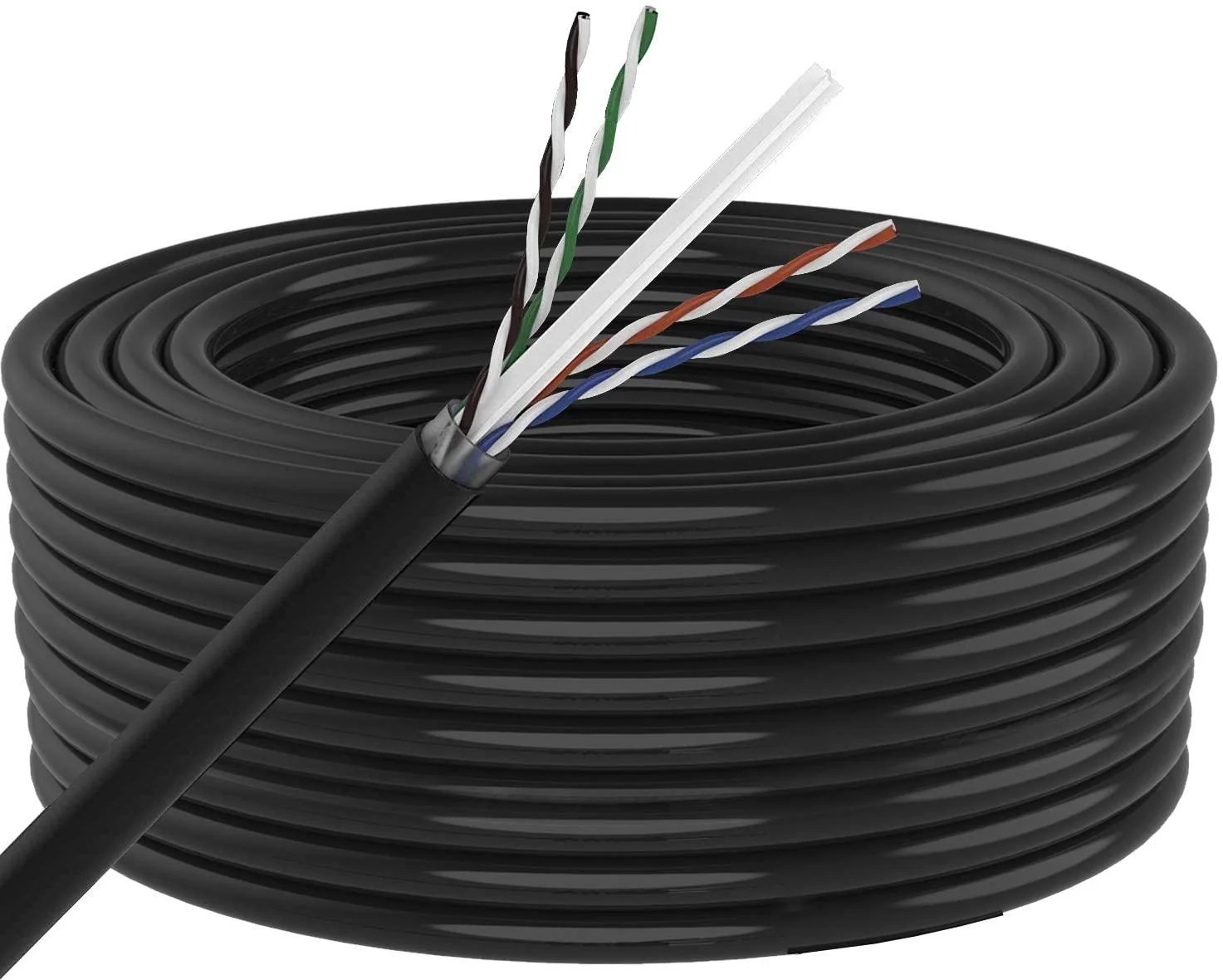

| Product Name | LAN CABLE CAT5E |

|---|---|

| Jackets | PVC, LSZH, PE |

| Color | Customized |

| Conductor | 24AWG CCA |

| Logo | OEM |

| Industrial Use | Network data |

| Origin | Hangzhou Zhejiang |

Product Specifications

| Conductor | 24AWG CCA |

|---|---|

| Core | 4Pair stranded conductor |

| Insulation | HDPE Retardant meet the requirement of IEC |

| Outer Jacket | PVC, PE Flame Retardant meet the requirement of IEC |

| Shielding | None |

Product Manufacturing Process

The manufacturing process of Cat5e gel-filled cables involves several critical steps to ensure high durability and performance. First, the 24AWG CCA conductors are twisted into pairs, which helps in minimizing electromagnetic interference and crosstalk. Then, a hydrocarbon gel is applied around these pairs, providing moisture resistance and corrosion mitigation. The gel-filled cables are passed through sheath production lines, where jackets made of PVC, LSZH, or PE are applied. The finished cables undergo rigorous testing, including FLUKE tests, to ensure they meet performance standards. This meticulous manufacturing process ensures that the cables can withstand harsh environmental conditions, making them ideal for outdoor and industrial applications.

Product Application Scenarios

Cat5e gel-filled cables are principally used in environments where durability and moisture resistance are paramount. They are ideal for outdoor installations such as direct burial and aerial installations. In industrial environments like factories and warehouses, where cables can be exposed to extreme conditions, these gel-filled cables provide the necessary durability. They are also used in marine applications where moisture and salt pose significant threats to standard cables. In all these scenarios, the primary benefit of using Cat5e gel-filled cables is their enhanced reliability and longevity, ensuring consistent performance over time.

Product After-Sales Service

We provide comprehensive after-sales support for our Cat5e gel-filled cables. This includes technical assistance, warranty services, and troubleshooting support. Customers can reach out to our dedicated support team via email or phone for any issues or queries.

Product Transportation

Our Cat5e gel-filled cables are packaged in normal export packaging and shipped from the Ningbo port. We ensure that the cables are securely packaged to prevent any damage during transit. The minimum order quantity is 50km, and we have a supply ability of 25,000KM per year.

Product Advantages

- Longevity: The hydrocarbon gel filling protects the cable's internal structure, extending its lifespan.

- Enhanced Reliability: Moisture-resistant properties ensure consistent performance.

- Versatility: Suitable for both demanding and less challenging environments.

Product FAQ

1. What are the main benefits of using Cat5e gel-filled cables?

As a manufacturer, we ensure that our Cat5e gel-filled cables provide enhanced durability and moisture resistance, making them ideal for outdoor and industrial applications. The cables are designed to withstand harsh environmental conditions, ensuring long-term performance and reliability.

2. What materials are used in the Cat5e gel-filled cables?

The cables consist of 24AWG CCA conductors surrounded by hydrocarbon gel for moisture resistance. The outer jackets are made of PVC, LSZH, or PE, meeting IEC flame retardant requirements. As a manufacturer, we only use high-quality materials to ensure product reliability.

3. How does the gel filling enhance the cable's performance?

The hydrocarbon gel filling provides moisture resistance and prevents corrosion, ensuring the cable's internal structure remains intact even in harsh conditions. This results in enhanced longevity and consistent performance, making these cables ideal for various demanding environments.

4. Can the Cat5e gel-filled cables be used for direct burial?

Yes, the gel-filled Cat5e cables are suitable for direct burial without the need for additional conduit. The gel filling ensures protection against moisture and soil acidity, making them ideal for underground installations. As a manufacturer, we recommend assessing the specific environmental conditions to maximize the benefits.

5. What testing do the Cat5e gel-filled cables undergo?

Our Cat5e gel-filled cables undergo rigorous testing, including FLUKE tests, to ensure they meet performance standards. These tests verify the cable's data transmission capabilities and resistance to environmental factors, ensuring they are reliable for demanding applications.

6. Are these cables suitable for marine applications?

Yes, the Cat5e gel-filled cables are ideal for marine applications where moisture and salt pose significant threats to standard cables. The gel filling provides a higher degree of reliability, making these cables suitable for ships or offshore platforms.

7. What is the minimum order quantity for the Cat5e gel-filled cables?

The minimum order quantity for our Cat5e gel-filled cables is 50km. We have a supply ability of 25,000KM per year, ensuring we can meet large-scale demands. As a manufacturer, we offer competitive pricing and reliable delivery times.

8. How should the Cat5e gel-filled cables be handled during installation?

During installation, care must be taken to maintain the integrity of the gel filling. Cutting or stripping the cable should be done with precision to avoid displacing the gel. Additional cleaning may be required to remove any excess gel from the exposed wires. As a manufacturer, we provide installation guidelines to ensure proper handling.

9. What makes these cables suitable for industrial environments?

The Cat5e gel-filled cables are designed to withstand extreme conditions commonly found in industrial environments such as factories and warehouses. The gel filling provides durability and moisture resistance, ensuring reliable performance in challenging settings.

10. Can these cables be used for aerial installations?

Yes, the Cat5e gel-filled cables are suitable for above-ground installations where they may be exposed to the elements. The gel keeps the wires safe from rain and wind-driven moisture, making them reliable for aerial applications.

Product Hot Topics

1. Enhanced Durability of Cat5e Gel-Filled Cables

As a leading manufacturer of Cat5e gel-filled cables, we ensure that our products provide enhanced durability for various applications. The hydrocarbon gel filling offers moisture resistance, making these cables suitable for outdoor and industrial environments. Our customers have reported consistent performance and reliability, even in harsh conditions, highlighting the durability of our Cat5e gel-filled cables.

2. Moisture Resistance in Cat5e Gel-Filled Cables

The primary advantage of our Cat5e gel-filled cables is their exceptional moisture resistance. The hydrocarbon gel filling prevents moisture ingress, ensuring the internal structure remains intact over time. This feature is particularly beneficial for installations in areas with high humidity, rain, or snow. As a manufacturer, we take pride in providing cables that perform reliably in challenging environmental conditions.

3. Cost-Effectiveness of Cat5e CCA Cables

Our Cat5e cables with CCA conductors offer a cost-effective solution for customers with budget constraints. While CCA is cheaper than copper, our cables still meet performance standards, making them suitable for various networking needs. We provide both FLUKE-tested and non-FLUKE-tested options to cater to different requirements. As a manufacturer, we ensure that even our budget-friendly options provide reliable performance.

4. Versatility of Cat5e Gel-Filled Cables

The versatility of our Cat5e gel-filled cables makes them a reliable choice for a wide range of applications. Whether for outdoor installations, industrial environments, or marine applications, these cables provide consistent performance and enhanced reliability. As a manufacturer, we design our cables to be adaptable to various challenging scenarios, ensuring customer satisfaction.

5. Importance of Gel-Filled Cables in Harsh Environments

In harsh environments, standard cables often fail to provide the necessary reliability and performance. Our Cat5e gel-filled cables are specifically designed to address these challenges. The hydrocarbon gel filling provides moisture resistance and prevents corrosion, ensuring long-term performance. As a manufacturer, we recommend these cables for outdoor and industrial installations where durability is crucial.

6. Customer Satisfaction with Cat5e Gel-Filled Cables

Customer satisfaction is a top priority for us as a manufacturer of Cat5e gel-filled cables. Our customers have consistently reported high levels of satisfaction with the durability, performance, and reliability of our cables. We provide comprehensive after-sales support and technical assistance to ensure that our customers' needs are met. The positive feedback we receive reflects our commitment to quality and customer satisfaction.

7. Installation Guidelines for Cat5e Gel-Filled Cables

Proper installation is crucial to maintaining the integrity of Cat5e gel-filled cables. As a manufacturer, we provide detailed installation guidelines to ensure correct handling and placement of the cables. It is important to avoid displacing the gel filling during cutting or stripping. Additionally, cleaning any excess gel from exposed wires is necessary for secure connectorization. Following these guidelines ensures optimal performance of the cables.

8. Comparing Cat5e and Cat6 Cables

While Cat6 cables offer higher performance, Cat5e cables remain a popular choice due to their cost-effectiveness and suitability for most networking needs. Our Cat5e gel-filled cables provide enhanced durability and moisture resistance, making them ideal for outdoor and industrial applications. As a manufacturer, we offer both Cat5e and Cat6 cables, allowing customers to choose the option that best meets their requirements and budget.

9. The Role of CCA Conductor in Cat5e Cables

CCA (Copper-Clad Aluminum) conductors provide a cost-effective alternative to pure copper conductors. While they are cheaper, our Cat5e cables with CCA conductors still meet performance standards for most networking needs. For customers seeking better performance, we offer CCA cables with higher copper content that pass FLUKE tests. As a manufacturer, we ensure that our CCA conductor cables provide reliable performance at a lower cost.

10. Environmental Considerations for Cat5e Gel-Filled Cables

When choosing cables for outdoor and industrial installations, it's important to consider environmental factors. Our Cat5e gel-filled cables are designed to withstand harsh conditions, including moisture, extreme temperatures, and soil acidity. The hydrocarbon gel filling provides enhanced protection, ensuring long-term performance. As a manufacturer, we recommend assessing the specific environmental conditions to maximize the benefits of our gel-filled cables.

Image Description