Product Details

| Parameter | Specification |

|---|---|

| Conductor | Bare copper, class 5 |

| Insulation | PVC compound TI1 |

| Outer Sheath | Grey PVC compound TM2 |

| Nominal Voltage | 300/500 V |

| Test Voltage | 3,000 V AC |

| Temperature Range | Flexible: -5 to 70°C, Fixed: -40 to 80°C |

Common Product Specifications

| Number of Cores & Cross Sectional Area (mm2) | Outdoor Diameter (mm) | Weight (kg/km) |

|---|---|---|

| CY 3G0.5 | 6.1 | 59 |

| CY 4G0.5 | 6.5 | 71 |

| CY 5G0.5 | 7.0 | 86 |

| CY 7G0.5 | 7.5 | 105 |

Product Manufacturing Process

6 core control cable manufacturing involves precise processes that ensure quality and performance. Initially, the copper conductors are drawn and annealed to achieve the desired flexibility and conductivity. These conductors are then insulated with high-grade polymer materials like PVC or XLPE, providing electrical and thermal protection. The insulated cores are stranded together, ensuring compactness and flexibility. A protective outer sheath is added, often made of LSZH compounds to minimize hazardous emissions in case of fire. This sheath protects against environmental stressors. Throughout the manufacturing process, rigorous testing is conducted to ensure compliance with international standards for safety and efficiency.

Product Application Scenarios

6 core control cables are essential in various industries, attributing to their versatility and reliability. In industrial automation, these cables link sensors and control units, facilitating seamless communication in automated systems, enhancing efficiency and precision. In building management systems, they connect HVAC systems, lighting, and security controls, ensuring centralized and efficient building operations. These cables are also crucial in transportation, providing reliable connections between control panels and operational components, enhancing safety and functionality. Additionally, in telecommunications, they ensure stable signal transmissions between system components, crucial for effective communication networks.

Product After-Sales Service

We at Aston Cable prioritize customer satisfaction with comprehensive after-sales services. Our technical support team is available to assist with installation queries and any operational issues. We provide a warranty period that guarantees product performance and quality. For any manufacturing defects, our return and replacement policy ensures quick resolution, minimizing downtime for our clients.

Product Transportation

Our products are packaged securely to prevent damage during transit. Depending on the destination, transportation is organized via road, air, or sea, ensuring timely delivery. We offer tracking facilities to keep our clients informed of their shipment status.

Product Advantages

- Versatility: Suitable for multiple applications, reducing the need for various cables.

- Reliability: Robust construction ensures durability under challenging conditions.

- Cost-Effectiveness: Reduces material and installation costs by consolidating multiple functions into one cable.

- Safety: High-quality insulation prevents electrical hazards, ensuring safe operation.

Product FAQ

What voltage is the 6 core control cable rated for?

As a leading manufacturer, our 6 core control cables are rated for a nominal voltage of 300/500 V, suitable for a wide range of industrial applications.

Is the 6 core control cable suitable for outdoor installation?

Yes, but it requires UV protection to ensure longevity when used outdoors. Our sheaths are designed to withstand various environmental conditions.

What materials are used for insulation?

Our cables use PVC or XLPE for insulation, materials known for their durability and thermal resistance, ensuring safe and efficient power transmission.

Does the cable have EMI shielding?

Yes, our cables can include a tinned copper braid as shielding to prevent electromagnetic interference, crucial for maintaining signal integrity.

What is the minimum bending radius for installation?

For fixed installations, the minimum bending radius is 12.5 times the cable diameter, allowing flexibility in tight spaces.

Can the cable be used in damp environments?

Our 6 core control cables are suitable for use in dry, damp, and wet rooms, ensuring versatility across different environments.

Are there specific temperature limits for operation?

The cables are designed for a temperature range of -5 up to 70°C for flexible use, and -40 up to 80°C for fixed installations.

Is customization available for the 6 core control cable?

As a manufacturer, we offer customization options including length, color, and branding, tailored to meet specific customer needs.

How does the cable handle chemical exposure?

The outer sheath is resistant to certain chemicals and oils, enhancing durability and reliability in industrial environments.

What standards do the cables comply with?

Our 6 core control cables comply with international standards such as IEC and VDE, ensuring high safety and quality levels.

Product Hot Topics

Importance of EMI Shielding in Control Cables

Electromagnetic interference can significantly affect the performance of electrical systems. Our 6 core control cables, as a reputable manufacturer, come with optional EMI shielding, which helps maintain signal quality in environments with high electromagnetic activity. This shielding is crucial for applications in telecommunications and industrial settings where signal integrity is paramount.

Choosing the Right Cable for Industrial Automation

When selecting cables for industrial automation, it is vital to consider flexibility, durability, and resistance to environmental stressors. Aston Cable's 6 core control cables are designed to meet these needs, offering a reliable solution for connecting sensors and control units. Their robust construction ensures long-lasting performance, making them a preferred choice among manufacturers.

Advantages of LSZH Sheathing

Low Smoke Zero Halogen (LSZH) sheathing is an essential feature of our control cables. In the event of a fire, LSZH materials minimize the emission of smoke and harmful gases, ensuring higher safety standards in enclosed spaces. As a top manufacturer, we prioritize safety, making our cables suitable for use in buildings and transport vehicles where fire safety is critical.

Customization in Cable Manufacturing

Customization allows companies to meet specific operational needs. At Aston Cable, we offer bespoke solutions for our 6 core control cables, accommodating different lengths, colors, and branding requirements. This flexibility ensures our clients receive products tailored to their exact specifications, enhancing their system efficiency and brand presence.

Impact of Temperature Variations on Cable Performance

Temperature fluctuations can impact the performance of control cables. Our products are engineered to operate efficiently across a wide temperature range, making them suitable for diverse environments. By providing reliable performance under extreme conditions, we reinforce our position as a leading manufacturer in the cable industry.

Environmental Impact of Cable Production

As a responsible manufacturer, we are committed to minimizing our environmental footprint. Our production processes are designed to comply with ISO14001 standards, emphasizing sustainability. By choosing Aston cable, customers contribute to environmental conservation while receiving high-quality products.

Innovations in Cable Technology

Cable technology is continuously evolving, with manufacturers like Aston Cable at the forefront. We invest in R&D to enhance our products' functionality and efficiency, keeping pace with industry advancements. Our 6 core control cables reflect these innovations, providing cutting-edge solutions for modern applications.

Ensuring Cable Longevity

Longevity is a critical factor in cable selection. Our 6 core control cables are constructed using premium materials and undergo rigorous testing to ensure they withstand physical and environmental stresses over time. This durability helps reduce maintenance costs and enhances system reliability for our clients.

Role of Control Cables in Telecommunications

In telecommunications, reliable signal transmission is essential. Our 6 core control cables facilitate effective communication by providing stable connections. As a leading manufacturer, we ensure our products meet high standards for performance and durability, supporting the seamless operation of telecom networks.

Addressing Cable Installation Challenges

Installation can pose challenges, especially in complex systems. Our cables are designed for flexible and straightforward installation, featuring a suitable bending radius and clear identification marks. Manufacturers choose Aston Cable for our focus on ease of use and reliability, ensuring efficient system setup and operation.

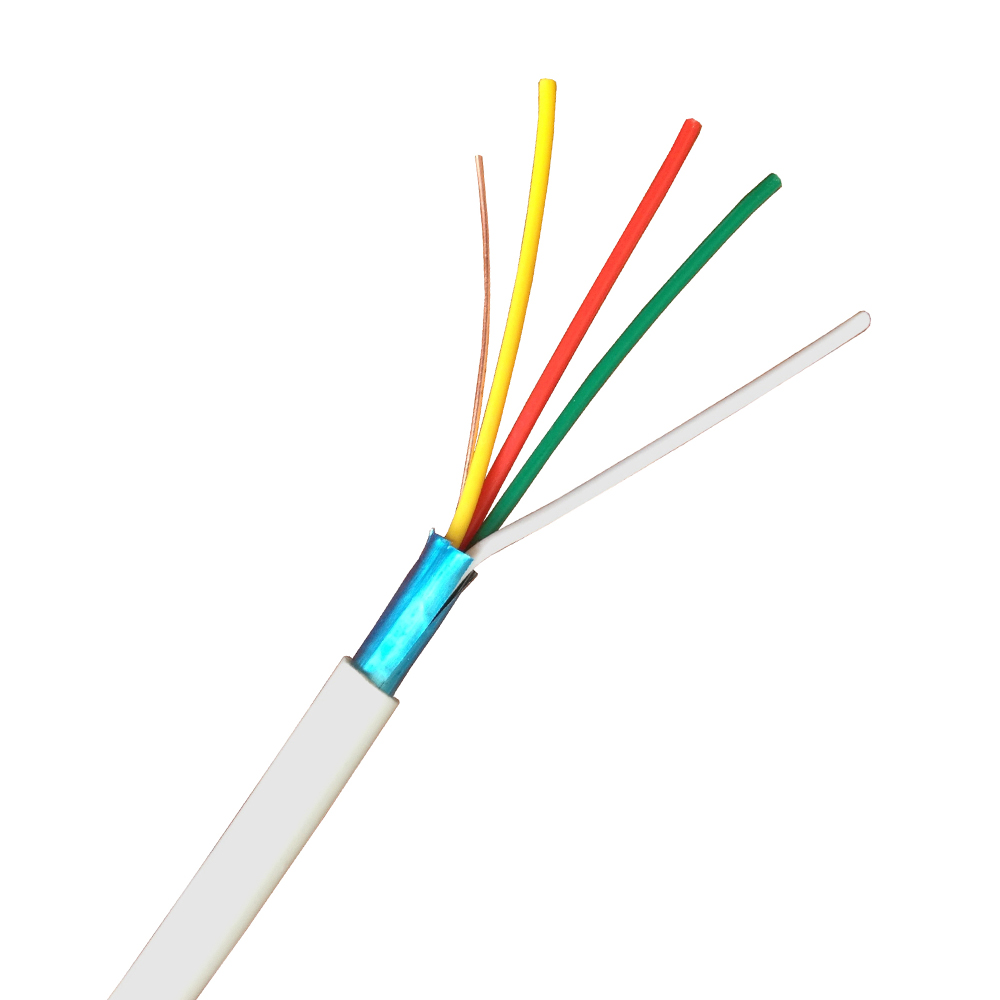

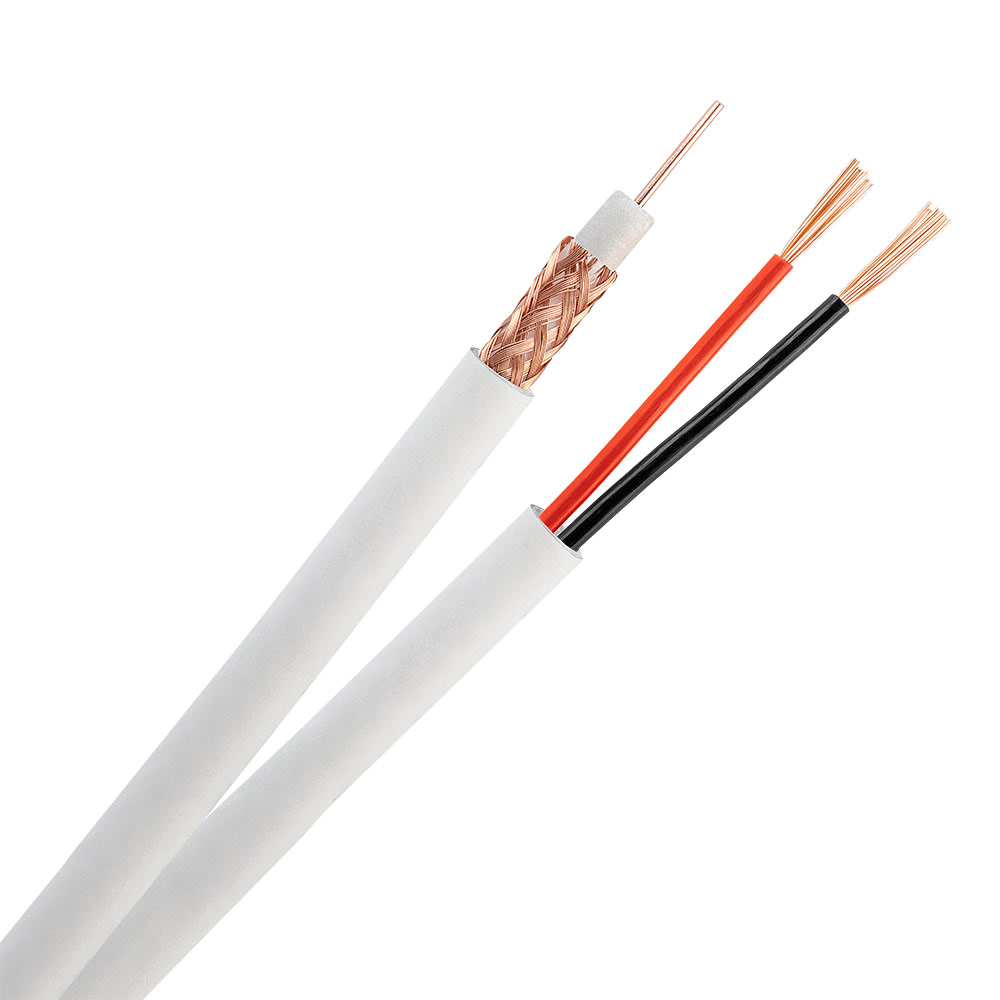

Image Description