Product Main Parameters

| Parameter | Details |

|---|---|

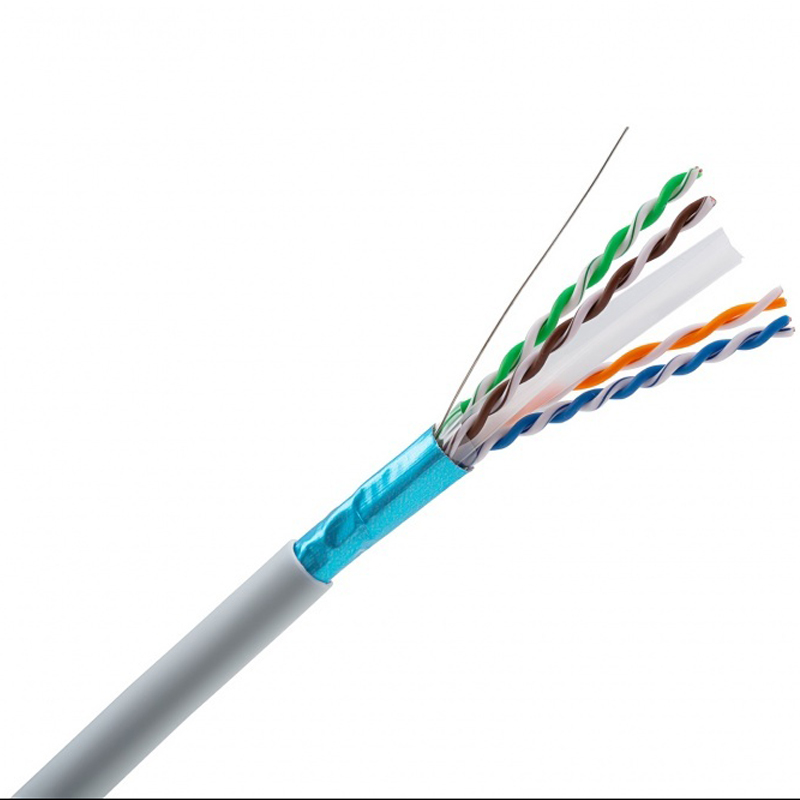

| Conductor | 23AWG Bare Copper |

| Jackets | PVC, LSZH, PE |

| Shielding | Aluminum/Polyester Foil & Al Braiding |

Common Product Specifications

| Specification | Details |

|---|---|

| Outer Diameter | Bigger due to complex structure |

| Flame Retardant | Meets IEC requirements |

| MOQ | 200 Rolls*305m |

Product Manufacturing Process

According to a range of authoritative papers, the manufacturing process for SF/UTP CAT6 control cable wire by a professional manufacturer involves several precision steps to optimize performance and reliability. Initially, high-purity raw copper is drawn into 23AWG conductors, which is a critical step for maintaining superior conductivity and flexibility. The conductors are twisted into pairs and then covered with a PE insulation layer to ensure signal integrity and prevent short circuits. A layer of aluminum foil is applied to each pair, complemented by a braided shield that offers additional protection from electromagnetic interference (EMI). The entire assembly is then encased in a durable outer jacket made from materials such as PVC or LSZH, which provide flame retardance and weather resistance. The stringent quality control standards adhered to during the production process ensure that the final product meets international standards like ISO9001, CE, and RoHS.

Product Application Scenarios

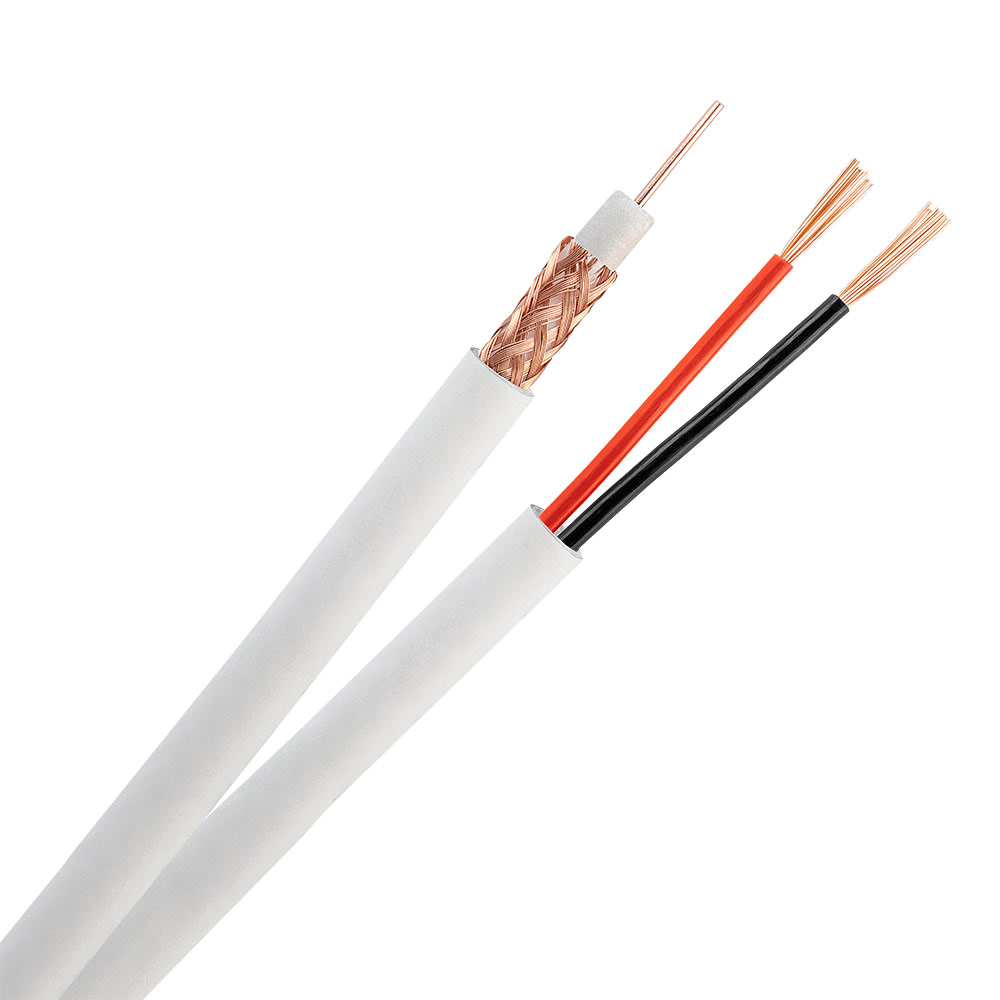

Control cable wires are crucial in various settings, each scenario demanding specific properties and characteristics. In industrial automation, these wires play a pivotal role in connecting machinery, sensors, and control units, thereby ensuring efficient and reliable system operation, as highlighted by recent studies. The transportation sector uses these cables for signaling and control in complex networks like railways and urban traffic systems, where precision and reliability are paramount. Energy and utility sectors utilize control cables for data transmission in power plants and substations, as maintaining operational safety and efficiency is critical. Furthermore, with the rise of smart buildings, control cable wires are increasingly used in building management systems, including the integration of HVAC, lighting, and security surveillance systems. The diversity of applications underscores the importance of choosing the right type of control cable for specific needs, as emphasized in published technical papers.

Product After-Sales Service

Our manufacturer-backed after-sales service ensures customer satisfaction with a focus on technical support and warranty coverage. Customers can access a 24/7 helpline for troubleshooting assistance and guidance on installation and maintenance. Additionally, we provide a standard warranty period that covers manufacturing defects and offers repair or replacement services as needed. We are committed to maintaining lasting customer relationships by offering extended warranty options and tailored service packages for long-term projects.

Product Transportation

Efficient product transportation is critical to maintaining the quality and reliability of our control cable wires. We utilize robust packaging solutions to protect cables from damage during transit, ensuring they reach customers in optimal condition. Our logistics partners are carefully selected to provide timely deliveries worldwide, with detailed tracking information available to customers. We cater to specific shipping needs, offering both standard and express options to accommodate various project timelines.

Product Advantages

- Reliability: Engineered to withstand various stresses, including mechanical and environmental, ensuring consistent performance.

- Versatility: Available in multiple configurations, tailored for specific applications and environments.

- Safety: Constructed with flame-retardant materials, minimizing fire hazards and enhancing safety in critical settings.

- Efficiency: Superior shielding minimizes signal loss and interference, promoting efficient data transmission.

- Compliance: Meets international standards such as ISO9001, CE, and RoHS, ensuring adherence to quality and safety norms.

Product FAQ

- What materials are used in the conductor of the control cable wire?

The conductor is typically made from high-purity copper, offering excellent conductivity and flexibility. Some options include CCA (Copper-Clad Aluminum) for cost efficiency, but pure copper remains the premium choice for performance.

- How does the shielding in SF/UTP CAT6 cables reduce EMI?

SF/UTP cables use a combination of aluminum foil and braiding to shield against electromagnetic interference (EMI). The foil wraps each twisted pair, reducing crosstalk, while the braiding further blocks external interference, ensuring signal integrity.

- What are the advantages of using LSZH jackets?

LSZH (Low Smoke Zero Halogen) jackets are advantageous in environments where fire safety is crucial. They emit little to no toxic smoke when exposed to fire, protecting personnel and equipment from harmful emissions.

- What certifications do your control cable wires hold?

Our cables are certified to meet international standards, including ISO9001 for quality management, CE for European health and safety compliance, and RoHS for environmental standards. These certifications reflect our commitment to manufacturing excellence.

- How do I select the right control cable for my application?

Consider factors such as environmental conditions, mechanical stresses, and application-specific needs. Ensure the cable meets necessary certifications and consult with our experts for tailored recommendations to suit your project.

- What is the significance of flame retardant materials in control cables?

Flame retardant materials are vital in minimizing fire risks. They help prevent the cable from catching fire and limit the spread of flames, crucial for maintaining safety in critical installations.

- How do control cables differ from power cables?

Control cables are primarily designed for transmitting control signals, such as data and voice, rather than just power. They ensure coordinated operation of systems, unlike power cables which transfer electrical energy to equipment.

- What is the MOQ for OEM orders?

The minimum order quantity (MOQ) for OEM orders is 200 rolls at 305m per roll. Customization options, such as color and branding, are available to tailor the product to your needs.

- Can these cables be used in outdoor conditions?

Yes, our cables are equipped with durable outer jackets, such as PE, which offer resistance to weather elements, making them suitable for outdoor applications.

- How do you ensure product quality during manufacturing?

Our stringent quality control systems include rigorous testing at various stages of production. We utilize advanced manufacturing machines and adhere to ISO standards to ensure product excellence and reliability.

Product Hot Topics

- The Impact of Advanced Shielding in Control Cable Wires

Advanced shielding in control cable wires plays a crucial role in enhancing signal quality and reliability. As a manufacturer, we emphasize the importance of reducing electromagnetic interference (EMI) through superior shielding techniques. By employing both aluminum foil and braiding, our cables ensure minimal signal disruption even in environments with high EMI. This shielding efficacy is critical for applications in industrial automation, where precise data transmission is paramount. Moreover, the added layer of protection facilitates faster data rates, making these cables suitable for high-speed networks. Investing in advanced shielding translates to improved performance and longevity of control systems.

- The Role of Control Cable Wires in Smart Building Management

In the age of smart technologies, control cable wires are indispensable in building management systems. As a manufacturer, our focus is on developing cables that seamlessly integrate with modern building automation, enhancing efficiency and operational control. Our SF/UTP CAT6 cables ensure robust connections across systems such as HVAC, lighting, and security, enabling centralized management. The adaptability and reliability of our cables support real-time data transmission, crucial for optimizing energy use and improving safety. As smart buildings continue to evolve, the demand for high-quality control cable wires will rise, driving innovation and sustainability in construction.

Image Description