Product Main Parameters

| Parameter | Value |

|---|---|

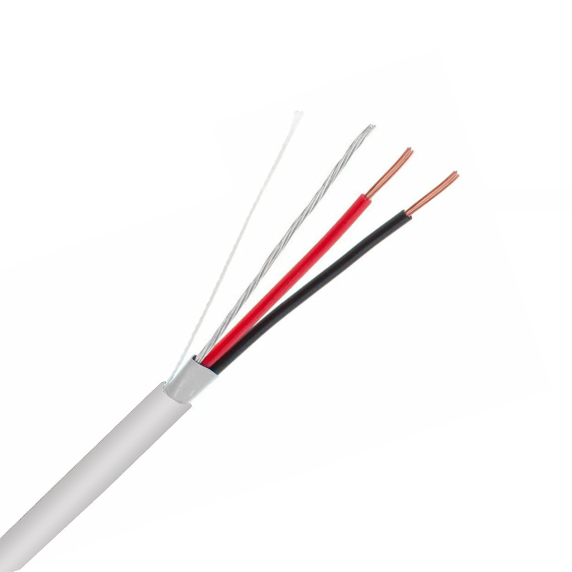

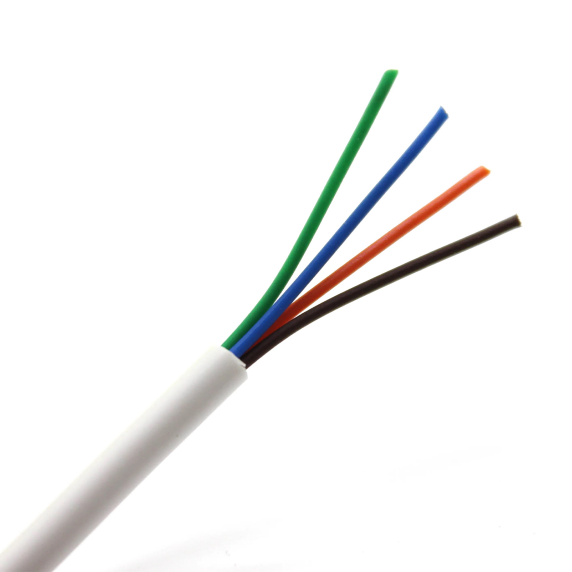

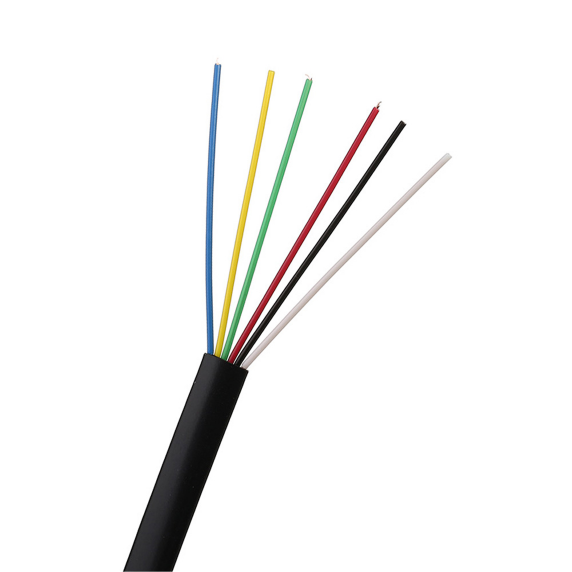

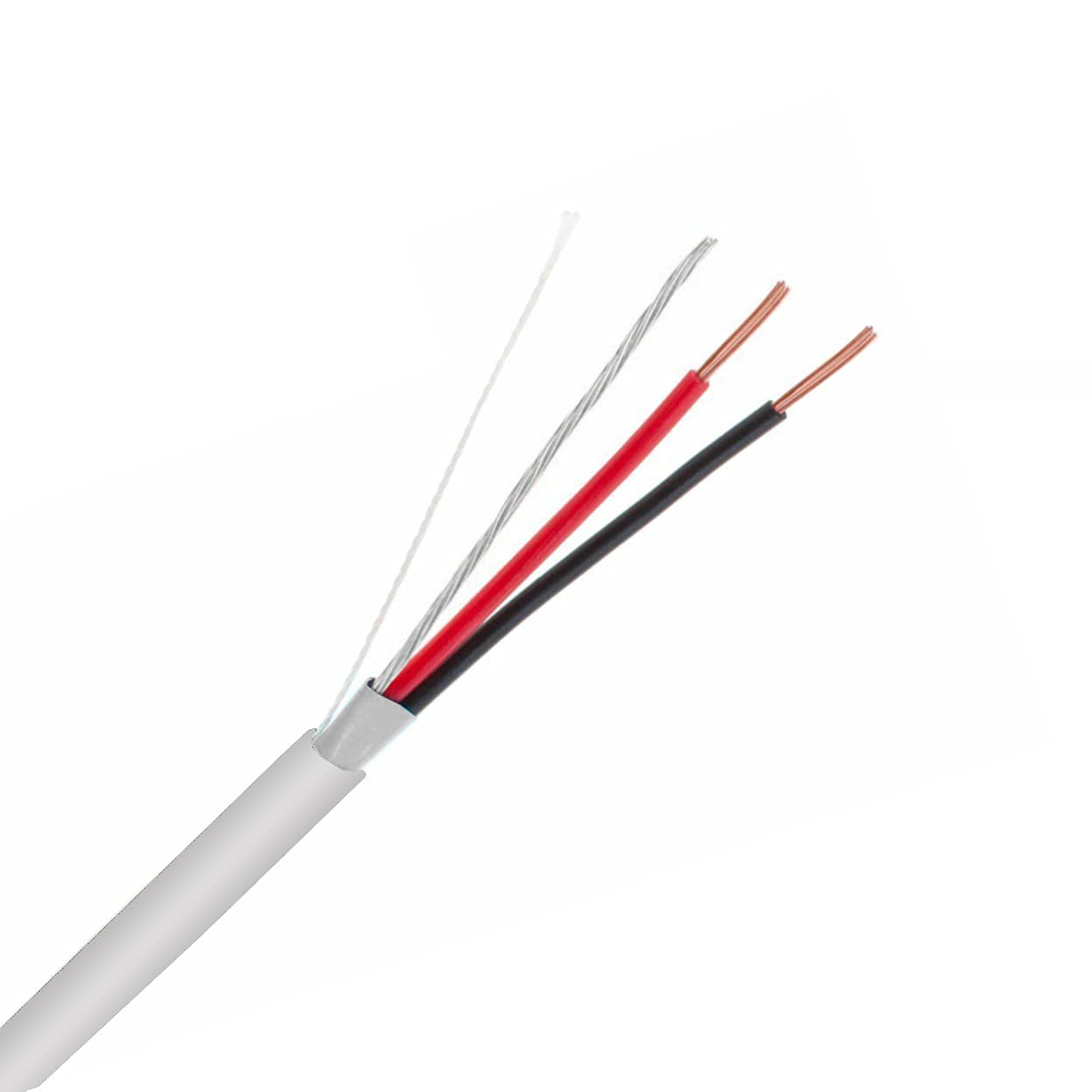

| Conductor | Bare Copper Solid or Stranded |

| Core | 2/4/6/8/10/12 |

| Insulation | PVC, LSZH, PE |

| Shielding | Aluminum/Polyester Foil |

| Outer Jacket | PVC, PE or LSZH |

| Color | White |

Common Product Specifications

| Specification | Description |

|---|---|

| Compliance | SGS, CE, ROHS, ISO9001 |

| Fire Ratings | FPL, FPLR, FPLP |

Product Manufacturing Process

According to authoritative sources, the manufacturing process of fire alarm cables involves several stages that ensure high-quality standards are met. The process begins with the precise extrusion of the conductor materials, typically copper strands that are drawn and annealed to enhance flexibility and conductivity. Insulating the conductors with flame-retardant materials follows, where PVC or LSZH is used due to their thermal resistance properties. A shielding layer may be applied to prevent electromagnetic interference, crucial for maintaining signal integrity, especially in electrically noisy environments. The final step involves applying an outer jacket that offers protection against environmental factors like moisture and mechanical damage. Rigorous testing at each step ensures compliance with standards set by organizations including NFPA and UL, ensuring the cables’ reliability and safety in critical situations.

Product Application Scenarios

Fire alarm cables are designed to meet stringent safety standards, making them indispensable in various settings. In residential buildings, they serve as the backbone of safety systems, connecting smoke detectors and other emergency devices to control panels. Their use extends to commercial spaces, such as offices and shopping centers, where compliance with fire safety codes is mandatory. Industrial environments pose additional challenges, requiring cables that can withstand harsher conditions such as higher temperatures and exposure to chemicals. Here, cables with specialized jackets and additional shielding are preferred. In all scenarios, the cables’ ability to reliably transmit signals under adverse conditions is crucial, ensuring timely alerts during emergencies and ultimately protecting lives and property.

Product After-Sales Service

Our committed after-sales team provides comprehensive support, ensuring satisfaction with every purchase. We offer expert technical assistance for installation and troubleshooting, and our warranty policies guarantee the quality and durability of our fire alarm cables. In case of any defects, our efficient return and replacement process ensures minimal disruption.

Product Transportation

All products are securely packaged for safe transit, with logistics partners ensuring timely delivery. We offer flexible shipping options depending on the destination, including express services for urgent requirements, and detailed tracking to monitor shipments in real-time.

Product Advantages

- Compliance with international standards ensures reliability and safety.

- High-quality materials provide durability and performance in various environments.

- Custom options for shielding and insulation to meet specific needs.

Product FAQ

What are the key specifications of fire alarm cables by manufacturers?

Leading manufacturers prioritize compliance with NFPA and UL standards, ensuring cables are flame-retardant and capable of maintaining signal integrity. Specifics like conductor material, shielding, and insulation type are selected based on application needs.

Why is compliance critical in fire alarm cable specifications?

Compliance ensures that fire alarm cables perform reliably in emergencies, reducing risks of failure and ensuring timely alerts. It aligns with safety standards critical for protecting life and property.

How do manufacturers ensure cable durability?

Durability is achieved through material selection and rigorous testing. Manufacturers use high-grade conductors and insulation materials designed to withstand environmental stressors. Quality control processes validate long-term performance.

Can these cables be customized?

Yes, manufacturers often offer customization options, including conductor size, shielding type, and insulation material, to meet specific application requirements. Custom solutions enhance performance in unique installation conditions.

Do fire alarm cables by manufacturers meet international standards?

Our cables meet and often exceed international standards such as UL and NFPA, ensuring they are suitable for global applications and comply with region-specific regulations.

Why do manufacturers use LSZH for insulation?

LSZH (Low Smoke Zero Halogen) is used for its safety properties, emitting minimal smoke and toxic gases in a fire scenario, thus enhancing occupant safety and meeting stringent safety codes.

What are the typical applications for these cables?

Fire alarm cables are commonly used in residential, commercial, and industrial settings to connect detection devices to alarm control panels, maintaining critical communication pathways in emergency situations.

How do manufacturers handle product defects?

Manufacturers prioritize quality but address defects through comprehensive warranties. Efficient return and replacement policies ensure customer satisfaction, with prompt attention to resolution.

What installation considerations are essential for fire alarm cables?

Key considerations include compliance with local codes, appropriate cable routing to prevent damage, and use of firestopping materials when penetrating rated assemblies. Proper installation ensures system reliability.

How do manufacturers ensure cable performance in fire scenarios?

Performance assurance involves selecting materials with flame-retardant properties, rigorous testing under simulated conditions, and adherence to safety standards, allowing cables to function effectively in emergencies.

Product Hot Topics

How manufacturers are enhancing fire alarm cable specification for future technologies?

Manufacturers are innovating by integrating smart technologies and IoT capabilities into fire alarm cables, improving real-time monitoring and remote diagnostics. These advances ensure more responsive emergency systems and promote proactive maintenance. Cutting-edge materials are being researched to increase cable resilience in extreme environments, ensuring operation continuity. The future of fire alarm cables lies in adaptability to emerging building technologies, ensuring safety and compatibility with smart building initiatives.

The impact of environmental regulations on fire alarm cable specification by manufacturers

Increasing global environmental awareness is pushing manufacturers to adopt eco-friendly materials and processes in fire alarm cables. Compliance with regulations such as RoHS and REACH, aimed at reducing hazardous substances, is becoming standard. This shift not only meets legislative demands but enhances product sustainability, aligning with corporate social responsibility goals. By embracing these changes, manufacturers are minimizing environmental impact while maintaining high safety and performance standards.

Why manufacturers emphasize fire alarm cable specification in high-rise buildings?

Fire alarm cables in high-rise buildings require stringent specifications due to the increased risk and complexity of evacuation. Manufacturers focus on enhanced fire-retardant properties and robust signal integrity, essential for coordinating complex emergency responses. These cables must comply with specific codes to prevent vertical fire spread through riser spaces, ensuring occupant safety. As urban landscapes evolve, manufacturers are continuously adapting specifications to meet the unique challenges of high-rise construction.

The role of advanced materials in fire alarm cable specification by manufacturers

Manufacturers are increasingly utilizing advanced materials to improve the safety and reliability of fire alarm cables. Innovations in insulation and jacketing materials, such as LSZH and FEP, offer superior fire resistance and lower toxicity emissions. These advancements contribute to enhanced performance in diverse applications, from residential settings to demanding industrial environments. As technology progresses, manufacturers are committed to integrating cutting-edge materials that meet evolving safety standards and operation needs.

How manufacturers are ensuring quality control in fire alarm cable production?

Quality control is paramount for manufacturers in the production of fire alarm cables. Utilizing state-of-the-art testing equipment, manufacturers conduct rigorous assessments of materials and completed products to ensure compliance with industry standards. Each stage of production undergoes meticulous checking, from raw material selection to final product inspection. By maintaining stringent quality control, manufacturers guarantee the reliability and safety of fire alarm cables in everyday use and emergency situations.

Adapting fire alarm cable specification for diverse climates: a manufacturer's approach

Manufacturers are adapting fire alarm cable specifications to perform effectively across diverse climates, addressing challenges such as extreme temperatures and humidity. This involves selecting materials with superior thermal properties and moisture resistance to ensure cable longevity and performance. Specialized coatings and insulation enhance protection against environmental stressors, proving crucial for installations in challenging climates. By tailoring specifications to withstand climate variations, manufacturers offer solutions that ensure consistent safety and functionality globally.

Collaboration between authorities and manufacturers in setting fire alarm cable specification standards

Close collaboration between regulatory authorities and manufacturers is crucial for establishing fire alarm cable specification standards. This cooperation ensures that evolving safety requirements are met, benefiting public safety and compliance. Manufacturers contribute practical insights and technical expertise, guiding the development of standards that reflect technological advancements and real-world application challenges. The synergy between regulatory bodies and manufacturers fosters innovation and improves safety outcomes across the industry.

The evolution of fire alarm cable specification in response to construction trends

As construction trends shift towards sustainable and smart buildings, fire alarm cable specifications by manufacturers are evolving. This evolution involves integrating environmentally friendly materials and ensuring compatibility with modern building technologies. Emphasis on minimal environmental impact aligns with green building certifications, while integration capabilities support seamless communication in intelligent building systems. Manufacturers are at the forefront, adapting specifications to meet the demands of future construction innovations.

The significance of plenum-rated cables in manufacturers' fire alarm cable specification

Plenum-rated cables are a critical component in a manufacturer's fire alarm cable specification due to their enhanced fire-retardant properties. Designed for installation in air circulation spaces, plenum-rated cables minimize smoke and toxic emissions during a fire, safeguarding occupants. They fulfill stringent safety standards, making them indispensable in environments requiring superior fire protection, such as commercial buildings and public facilities. Manufacturers emphasize these cables to address specific safety challenges and regulatory requirements.

Improvements in electromagnetic interference shielding: a manufacturer's enhancement in fire alarm cable specification

Enhancing shielding against electromagnetic interference (EMI) is a priority in manufacturers' fire alarm cable specifications. Effective shielding ensures signal integrity, essential for reliable communication between alarm system components. Manufacturers utilize advanced materials like aluminum mylar and cable designs to minimize EMI, accommodating environments with high electrical noise. These improvements result in cables that maintain performance in challenging settings, ensuring timely and accurate emergency alerts across system infrastructures.

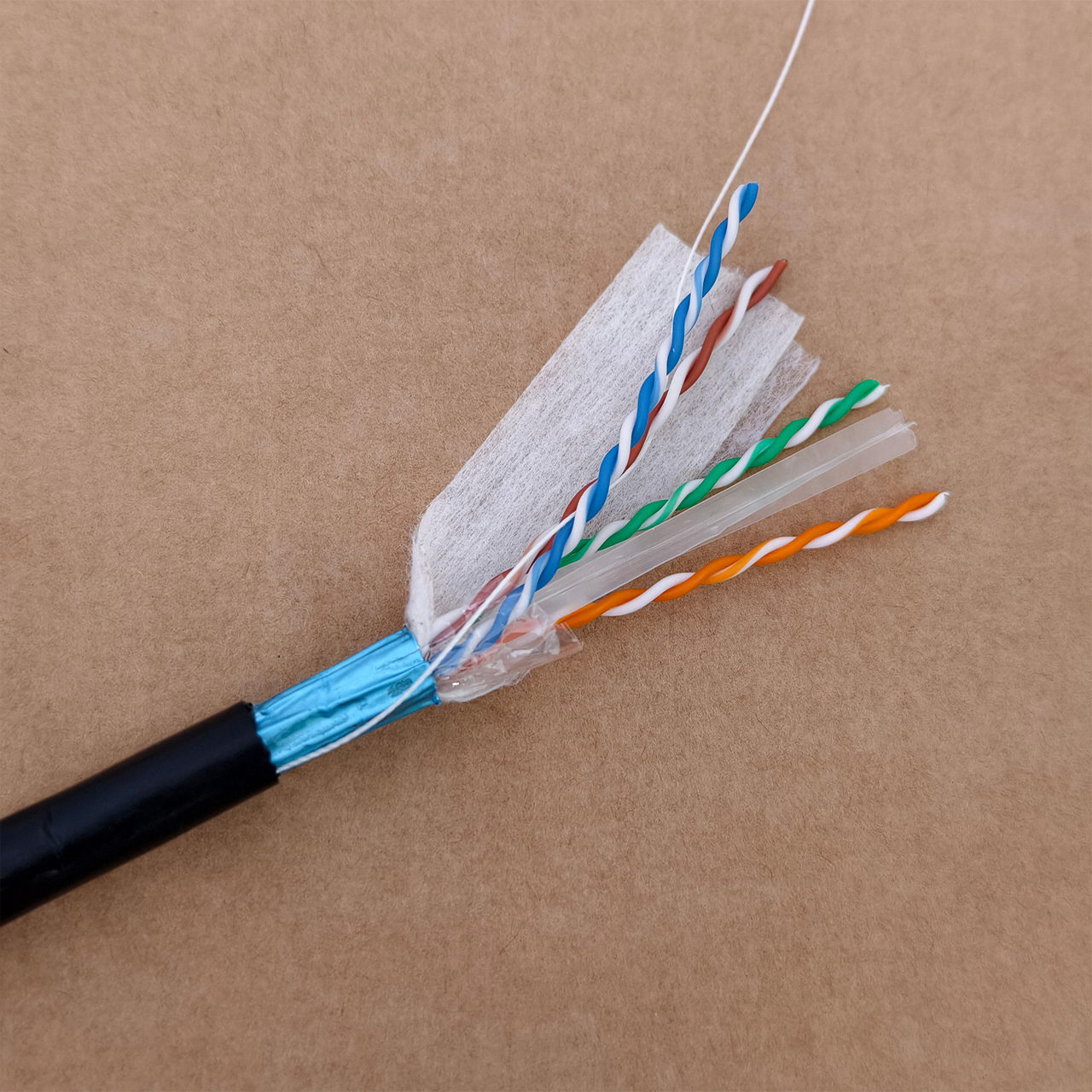

Image Description