Product Main Parameters

| Conductor Material | Copper/CCA |

|---|---|

| Insulation | HDPE |

| Outer Jacket | PVCPE |

| Flame Retardant | IEC Compliant |

Common Product Specifications

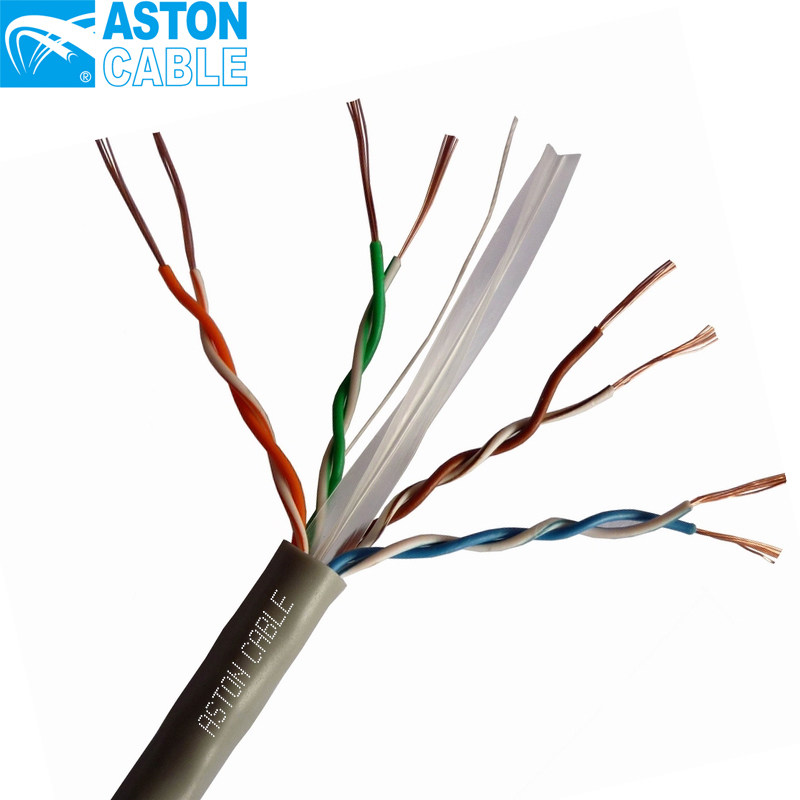

| Core | 4 Pair Stranded |

|---|---|

| Conductor Size | 24AWG |

| Color | Customized |

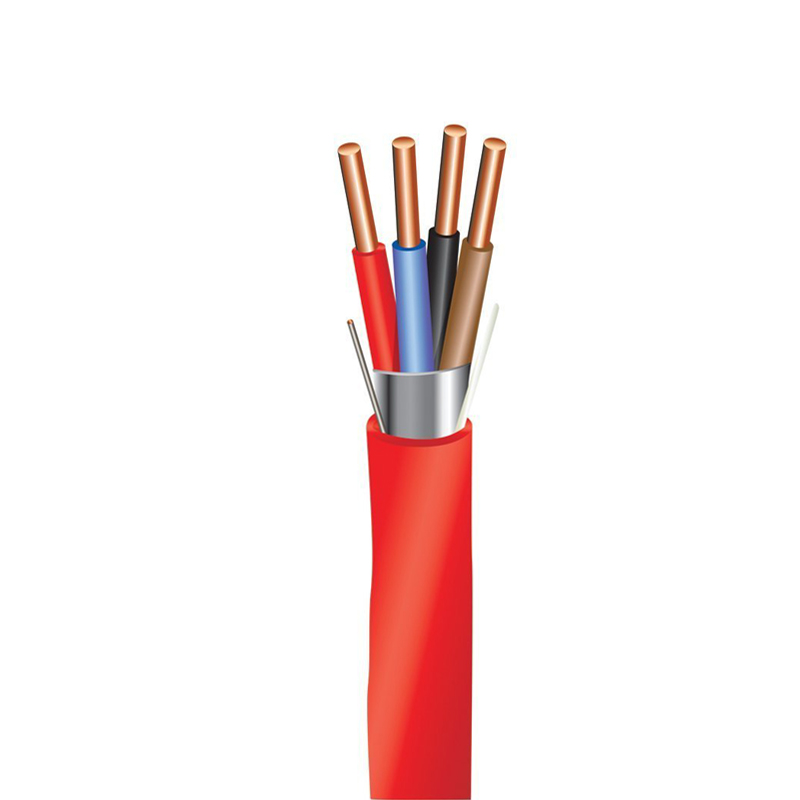

Product Manufacturing Process

The manufacturing of 4-core control cables involves several key steps: first, high-quality copper or copper-clad aluminum is drawn into conductors. These conductors are insulated with materials such as HDPE, known for its robust thermal and mechanical properties. In environments requiring additional protection against interference, conductors are shielded with braided copper or foil. The dual-layer structure of PVC and PE jackets ensures durability, with PE providing UV resistance for outdoor applications. The final step involves rigorous testing to ensure compliance with standards like IEC, guaranteeing high performance and reliability.

Product Application Scenarios

4-core control cables serve diverse applications, ranging from industrial automation to telecommunications. In industrial settings, these cables link machinery and control systems, ensuring efficient signal transmission. Building management systems use them for controlling subsystems such as HVAC and lighting. Telecommunications benefit from their reliability in transmitting control signals, while railway and transportation systems use them for signaling and communications. Robotics applications leverage their flexibility and durability for transmitting commands between control units and moving robotic parts.

Product After-Sales Service

We provide comprehensive after-sales service, including technical support, warranty claims, and replacement services. Our team of experts is available to assist you with any queries or issues you may encounter, ensuring complete satisfaction with our products.

Product Transportation

Our 4-core control cables are shipped with meticulous care to prevent any damage during transportation. We use robust, export-standard packaging solutions, and depending on the customer's location, we facilitate swift delivery through reliable logistics partners.

Product Advantages

- High-quality copper conductors ensure efficient signal transmission.

- The dual jacket design offers enhanced durability and UV resistance.

- Flexible design accommodates installations in complex environments.

- Compliance with international standards guarantees safety and reliability.

Product FAQs

1. What materials are used for the conductors in your 4-core control cables?

Our 4-core control cables are made with high-quality copper or copper-clad aluminum conductors. Copper provides excellent electrical conductivity, ensuring efficient signal transmission and flexibility during installation.

2. What is the purpose of having a dual jacket in these cables?

The dual jacket design, featuring PVC and PE, enhances the cable's durability. The PE outer layer provides UV resistance and robustness for outdoor installations, while the PVC inner layer ensures flexibility and suitability for indoor applications.

3. Are these cables shielded?

While our standard 4-core control cables come unshielded, we offer optional shielding for environments with high electromagnetic interference. Shielding involves a braided copper sheath or a foil layer to protect against such interference.

4. Can the cable colors be customized?

Yes, we offer customization options for cable colors to meet specific installation requirements or customer preferences. This can help with easy identification and organization during installations.

5. What specifications do these cables meet?

Our 4-core control cables comply with international standards such as IEC, CE, and RoHS. This compliance ensures high performance, safety, and reliability across various applications.

6. What are the payment terms?

Our payment terms are negotiable and can be tailored to meet customer needs. We accept various forms of payment, ensuring a smooth transaction process for our clients.

7. Do these cables support high-speed data transmission?

While primarily designed for control signal transmission, our 4-core control cables are built to support reliable, high-speed data transmission within automation and industrial systems.

8. How do these cables handle extreme temperatures?

Our cables are insulated with materials like HDPE, which offer excellent temperature resistance. This ensures they can function effectively in both high and low-temperature environments.

9. What is the typical lead time for delivery?

Our lead time for delivery varies based on order size and location but generally ranges from 2 to 4 weeks. We strive to deliver our products as swiftly and efficiently as possible.

10. Are these cables suitable for underwater applications?

While our standard 4-core control cables are not designed for direct underwater use, additional protective measures or specialized versions can be discussed for such specific requirements.

Product Hot Topics

1. How does the dual jacket design improve cable performance?

The dual jacket design significantly boosts cable performance by offering enhanced protection against environmental factors. The PVC inner layer provides flexibility and strength, whereas the PE outer layer adds UV resistance and makes the cable suitable for outdoor use. This combination ensures longevity and reliability, even in harsh conditions, making our 4-core control cables a preferred choice among manufacturers.

2. What makes copper the ideal choice for cable conductors?

Copper is known for its superior electrical conductivity, which is crucial for signal transmission in control cables. Its flexibility and durability also contribute to the cable's performance, making it a staple for manufacturers. In the context of 4-core control cables, copper allows for smooth communication between connected devices, minimizing signal loss and ensuring high efficiency.

3. Why is color coding important in control cables?

Color coding plays a vital role in the installation and maintenance of control cables. It aids technicians in identifying individual conductors quickly, speeding up the installation process and reducing errors. This is particularly important for manufacturers and installers who deal with complex wiring systems, ensuring that the correct connections are made efficiently.

4. What applications benefit the most from 4-core control cables?

4-core control cables are indispensable in a variety of applications such as industrial automation, telecommunications, and building management systems. Their ability to transmit control signals precisely makes them ideal for controlling machinery, HVAC systems, and security devices. Manufacturers rely on these cables to ensure the seamless integration and operation of various systems, highlighting their versatility and efficiency.

5. How do shielding options enhance cable performance in high-interference environments?

In environments with high electromagnetic interference, shielding is crucial for maintaining signal integrity. Manufacturers offer options like braided copper sheaths or foil layers to protect against such interference, ensuring that the 4-core control cables can operate without signal degradation. This enhancement is vital for applications where precision and reliability are non-negotiable.

6. What factors should be considered when selecting control cables?

When selecting control cables, several factors need to be considered, including the application environment, required flexibility, and resistance to environmental factors such as moisture and chemicals. Manufacturers must also consider the electrical load and any specific regulatory compliance requirements to ensure the chosen cables meet the necessary standards for safe and efficient operation.

7. How do advancements in material technology impact cable design?

Advancements in material technology continually enhance cable design by offering new insulation and jacket materials that improve cable performance. These materials offer better resistance to heat, chemicals, and mechanical wear, allowing manufacturers to produce cables that are more durable and reliable in demanding applications. This progress enables the development of 4-core control cables that meet the evolving needs of modern industries.

8. What is the future potential for 4-core control cables in smart technologies?

With the growing trend towards smart technologies, 4-core control cables are poised to play a pivotal role in connecting devices within smart systems. Their ability to facilitate precise control signals makes them ideal for integration into smart grids, homes, and factories. Manufacturers are continuously innovating to enhance these cables' capabilities, ensuring they can meet the demands of increasingly interconnected environments.

9. How do 4-core control cables contribute to energy efficiency?

By ensuring accurate and reliable signal transmission, 4-core control cables help optimize the performance of automated systems, directly contributing to energy efficiency. Manufacturers leverage these cables to minimize signal loss and reduce downtime, which in turn enhances the overall efficiency of systems they are integrated into. This contribution is critical for sectors focused on reducing energy consumption and improving sustainability.

10. How do manufacturers ensure the quality of 4-core control cables?

Manufacturers employ rigorous quality control processes to ensure the reliability of 4-core control cables. This includes comprehensive testing of electrical conductivity, insulation integrity, and environmental resistance. Adherence to standards such as ISO9001 and CE ensures that the cables meet the high-quality benchmarks required for demanding applications, providing customers with confidence in their long-term performance and safety.

Image Description