Product Main Parameters

| No. of Cores | Nominal Cross Sectional Area (mm²) | Nominal Thickness of Insulation (mm) | Nominal Thickness of Sheath (mm) | Nominal Overall Diameter (mm) | Nominal Weight (kg/km) |

|---|---|---|---|---|---|

| 2 | 0.75 | 0.4 | 0.8 | 7.2 | 79.3 |

| 2 | 1.0 | 0.4 | 0.8 | 7.6 | 91 |

| 3 | 1.5 | 0.4 | 0.8 | 8.2 | 110 |

Common Product Specifications

| Conductor | Class 5 flexible plain copper wires |

|---|---|

| Insulation | PVC (Polyvinyl Chloride) |

| Inner Sheath | PVC (Polyvinyl Chloride) |

| Armour | GSWB (Galvanised Steel Wire Braid) |

| Sheath | PVC (Polyvinyl Chloride) |

| Core Identification | Black with white number Green/Yellow |

| Sheath Colour | Transparent |

Product Manufacturing Process

Manufacturers of card access control cable systems utilize advanced techniques that ensure optimal performance and durability. The process begins with selecting high-quality copper for conductors, followed by insulating them with reliable PVC material. The conductors are carefully twisted into pairs to enhance EMI resistance. Next, a shielding layer, such as galvanized steel wire braid, is applied for mechanical and electromagnetic protection. The final assembly is encased in a durable PVC sheath, ensuring long-lasting integrity. Each step, from material selection to final assembly, undergoes stringent quality checks to comply with international standards, ensuring that each cable performs reliably in various environments.

Product Application Scenarios

Card access control cable systems are integral to various security environments. In corporate offices, they connect devices to central control units, ensuring seamless access management. In educational facilities, these cables maintain secure, efficient entry points, enabling a controlled environment. Government buildings benefit from robust cable systems that protect sensitive areas from unauthorized access. Healthcare institutions rely on these cables for secure, efficient access to critical areas and data. As technology and security requirements evolve, these cables provide scalable, adaptable solutions, making them indispensable in modern security infrastructure.

Product After-sales Service

Our after-sales service includes technical support, troubleshooting guidance, and cable replacement for defects. We ensure customer satisfaction by offering warranty services and responsiveness to inquiries. Our trained specialists provide installation advice and system optimization tips, helping you maximize the performance and longevity of your card access control cable systems.

Product Transportation

Cables are transported carefully to prevent damage, using reinforced packaging and moisture barriers. We partner with reliable logistics providers to ensure timely delivery, and offer tracking services for shipments. Our packaging is designed to protect cables during handling, minimizing the risk of transit-related issues.

Product Advantages

- Reliable communication and data integrity.

- Durable construction and flexible installation.

- Suitable for various security environments.

- High resistance to electromagnetic interference.

- Flexible deployment in scalable systems.

Product FAQ

- Q: What are the key features of your card access control cables?

A: Our cables are designed for durability, flexibility, and enhanced data security, equipped with high-quality copper conductors and effective EMI shielding. - Q: Can these cables be used outdoors?

A: Our standard SY armored cables are not intended for outdoor use, but we offer other options suitable for various environmental conditions. - Q: Do you offer customization for specific requirements?

A: Yes, as manufacturers, we can tailor our card access control cables to meet specific project needs, including length, jacket type, and additional features. - Q: What compliance standards do your cables meet?

A: Our products comply with ISO9001, ISO14001, RoHS, CE, and IEC standards, ensuring international quality and safety. - Q: How can I ensure optimal cable performance?

A: Ensure adherence to recommended installation guidelines, including maximum cable length and suitable environmental conditions. - Q: What is the warranty period for your cables?

A: We offer a comprehensive warranty that covers manufacturing defects and ensures customer satisfaction. - Q: Do you provide installation support?

A: Our team offers technical support and guidance for installation to ensure efficient deployment and performance of our cables. - Q: How do you handle cable returns?

A: We have a clear return policy, where faulty cables can be returned for assessment and replacement if necessary. - Q: What makes your cables unique compared to others?

A: Our cables are distinguished by their robust construction, EMI protection, and adaptability to various access control systems. - Q: How do you ensure product quality?

A: Through rigorous testing and adherence to international quality standards, we maintain high product quality across our cable range.

Product Hot Topics

- Comments on Installation Efficiency

Our card access control cables have been praised for their ease of installation, saving users time and labor costs. The composite design streamlines the process by combining power and data conductors, reducing the complexity of installation. Installers have noted the clear labeling and flexible structure as significant advantages, ensuring reliability and reducing potential for errors during setup. These features make our cables a preferred choice for both new installations and upgrades in access control systems. - Impact of Environmental Factors

Customers have commented on the durability of our card access control cables in various environments. The robust design, combined with quality materials, offers resilience against temperature fluctuations and moisture, making them suitable for a range of installations. OEM options are available for specialized applications, ensuring that our cables perform reliably even in challenging conditions, maintaining security and operational integrity.

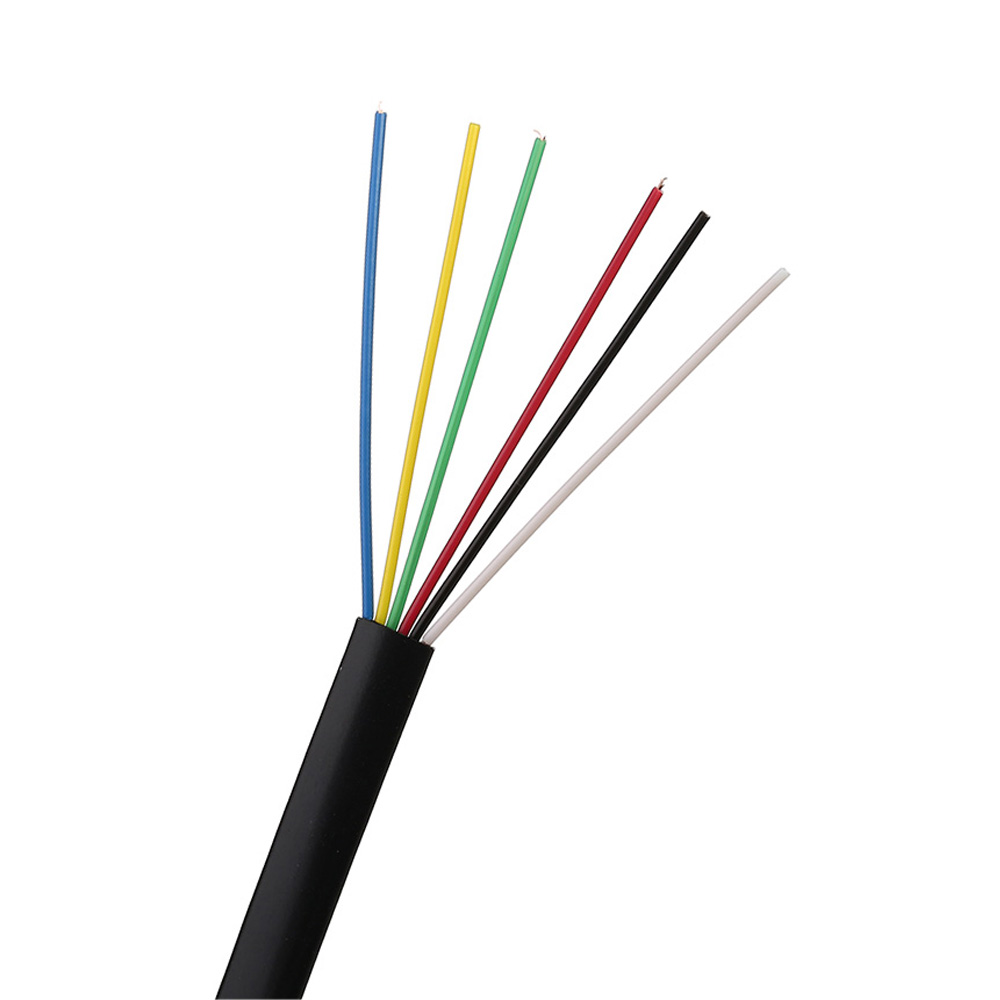

Image Description