Product Main Parameters

| Parameter | Details |

|---|---|

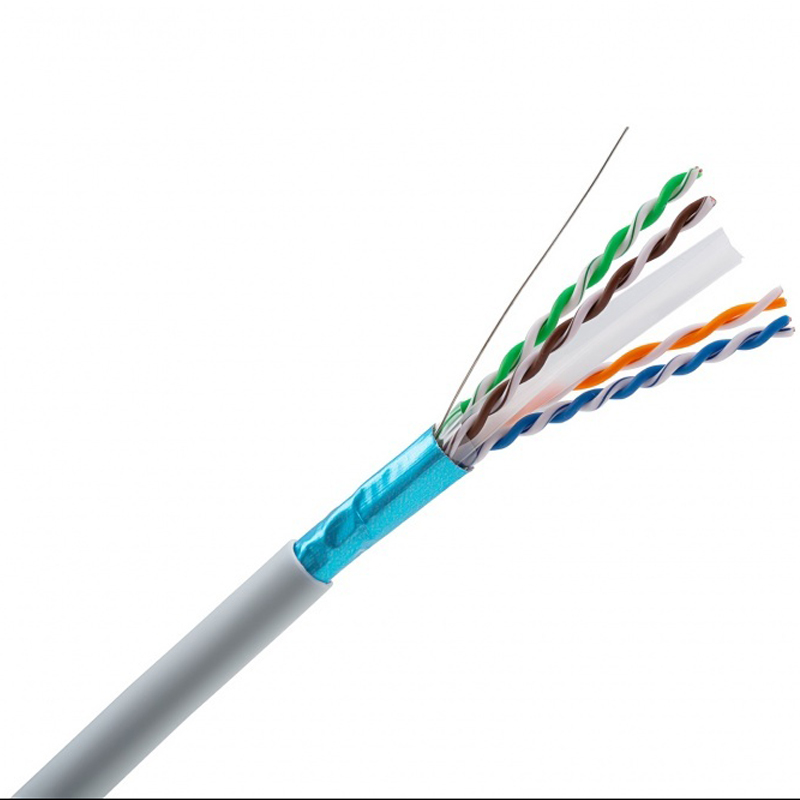

| Conductor Material | Bare Copper/CCA |

| Conductor Size | 23AWG Solid or Stranded |

| Insulation | PE, LSZH, PVC |

| Shielding | Aluminum Foil, Al Braiding |

| Outer Jacket | PVC, PE or LSZH |

Common Product Specifications

| Feature | Specification |

|---|---|

| Pairs | 4 Pairs Stranded |

| Flame Retardant | Meets IEC Standards |

| Shielding Coverage | 80%-98% Braiding Coverage |

Product Manufacturing Process

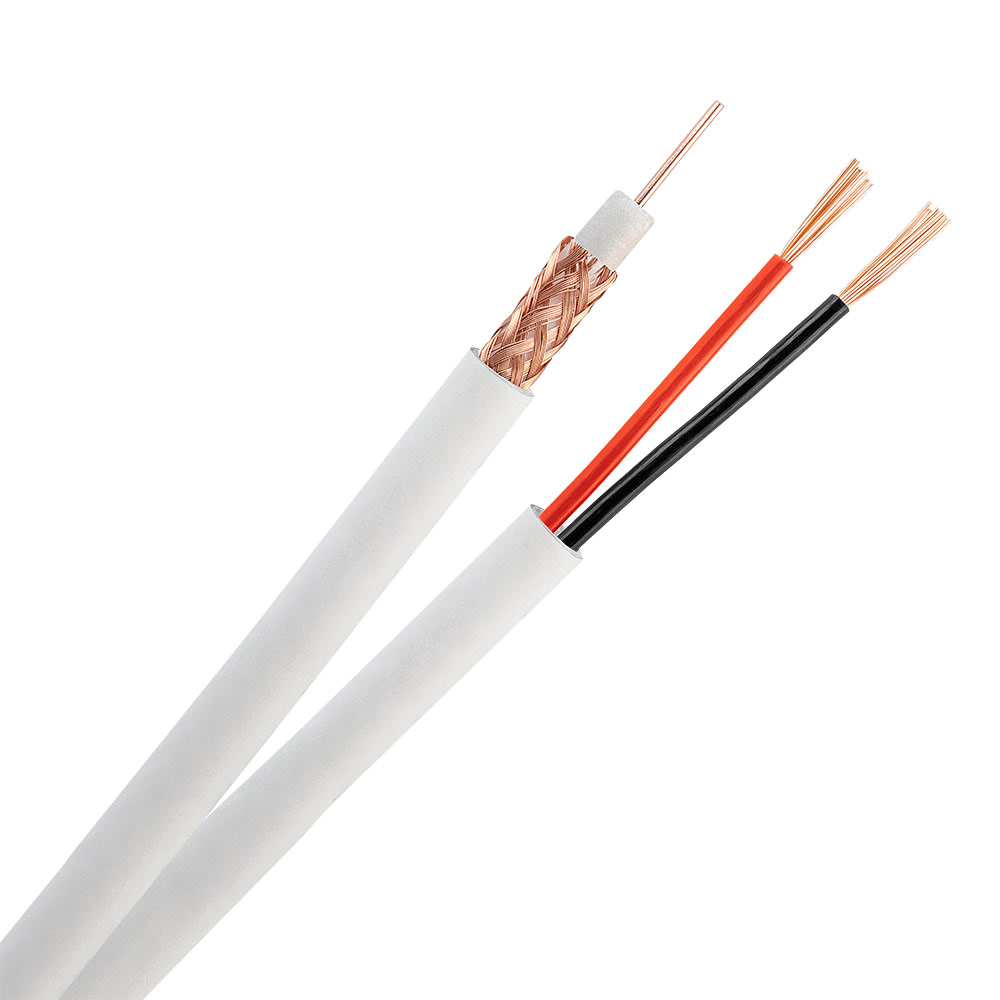

The manufacturing of multicore control cables involves several critical processes to ensure quality and performance. Initially, high-grade copper or copper-clad aluminum is drawn into fine strands. These strands are then twisted into pairs to minimize electromagnetic interference. The twisted pairs are next insulated with materials such as PVC or LSZH, chosen for their electrical and thermal properties. The insulated conductors are bundled together and may include a shielding layer of aluminum or foil braiding to further protect against interference. Finally, the cable is jacketed with a protective outer layer that serves to resist environmental damage. Throughout each step, strict quality controls are employed to maintain standards specified by manufacturers.

Product Application Scenarios

Multicore control cables find extensive utility across diverse industrial and commercial sectors. In industrial automation, these cables are vital for connecting and managing various automated equipment like robotics and conveyor systems, streamlining operational processes. In the realm of power distribution, they play a crucial role within control panels, enabling efficient system operation and load management. Moreover, they serve a pivotal function in communication systems, underpinning the transmission of data and signals in telecommunication infrastructures. Within building management systems, these cables support the integration and control of HVAC, lighting, and security solutions, enhancing the functionality of commercial and residential properties.

Product After-Sales Service

Aston Cable offers comprehensive after-sales service including technical support, installation guidance, and warranty coverage to ensure customer satisfaction and product performance.

Product Transportation

The product is securely packaged for export and transported through reliable channels with delivery available through Ningbo port. It ensures timely and safe delivery to minimize any potential for damage or loss.

Product Advantages

- Space Efficient: Multicore design reduces the need for multiple cables.

- Cost-Effective: Consolidated design reduces installation and maintenance costs.

- Durable: Protective sheath and robust insulation extend product lifespan.

Product FAQ

- What are multicore control cables used for? Manufacturers create these cables for transmitting multiple signals. They're ideal for industrial automation, power distribution, and communication systems due to their efficiency and reliability.

- What materials are used in the cable's construction? Typically, manufacturers use copper or copper-clad aluminum for conductors, while insulation options include PVC, PE, and LSZH for enhanced performance and safety.

- How do these cables handle interference? Multicore control cables often incorporate shielding, such as aluminum foil or braiding, to protect against electromagnetic interference, ensuring signal integrity.

- What are the advantages of LSZH insulation? LSZH reduces smoke emission in case of a fire, providing added safety in enclosed spaces compared to traditional PVC insulation.

- Can these cables be customized? Yes, manufacturers often offer customized solutions for specific industry requirements, including different jacket colors, materials, and conductor specifications.

- What standards do these cables meet? They are compliant with international standards such as IEC, CE, and RoHS, ensuring they meet rigorous safety and performance criteria.

- Are these cables suitable for outdoor use? With suitable sheathing and design, multicore control cables can be used in outdoor applications, given their resistance to environmental factors.

- What is the expected lifespan of these cables? With proper installation and usage, these cables can offer a prolonged lifespan, often exceeding several years, thanks to their durable design.

- How do I choose the right cable for my application? Consider factors like required voltage ratings, environmental conditions, and flexibility needs. Manufacturers can provide guidance based on your specific requirements.

- What after-sales support is available? Aston Cable provides extensive after-sales services, including installation guidance, technical support, and warranty assistance to ensure customer satisfaction.

Product Hot Topics

- Trend Analysis: Increasing Demand for Multicore Control Cables The demand for multicore control cables is rapidly growing, driven by advancements in industrial automation and the increasing complexity of engineering systems. Manufacturers who can provide bespoke solutions and innovative designs are seeing increased interest as industries aim to maximize efficiency.

- Innovations in Insulation Technologies Recent developments in insulation materials, such as low-smoke halogen-free options, are being embraced by manufacturers to enhance safety standards in critical applications. These innovations are increasingly necessary in environments where fire safety is paramount, such as high-density manufacturing facilities and data centers.

- Impact of IoT on Multicore Control Cable Market As the Internet of Things (IoT) continues to expand into various sectors, the role of multicore control cables is becoming more prominent. These cables provide the reliable communication lines needed for interconnected devices, cementing them as a staple in modern technological infrastructures.

- Environmental Considerations in Cable Manufacturing Manufacturers are increasingly focusing on creating environmentally-friendly cables to reduce their ecological footprint. This includes using recyclable materials and adopting manufacturing processes that minimize waste and energy consumption, aligning with global sustainability goals.

- Challenges in Shielding Technology While shielding is crucial for protecting signal integrity, manufacturers face challenges in balancing cost with the effectiveness of different shielding methods. Advances in material science are helping to develop solutions that offer efficient protection without compromising on affordability.

- Customizable Solutions for Niche Markets With diverse applications across multiple sectors, the capability to provide customized multicore control cables is a key differentiator for manufacturers. Tailored solutions meet specific performance and regulatory demands, offering significant value to niche markets.

- Cable Lifespan & Maintenance Understanding the factors that affect cable longevity is vital for maximizing utility and minimizing maintenance costs. Manufacturers advocate for routine checks and proper installation to extend the life of multicore control cables, ensuring sustained performance.

- Future of Multicore Control Cables in Electric Vehicle Industry As the electric vehicle market expands, the role of multicore control cables is crucial in vehicle systems, supporting various functions from power distribution to communication. Manufacturers are increasingly focusing on this burgeoning sector for growth opportunities.

- The Role of Multicore Control Cables in Smart Grid Technologies As smart grid technologies advance, multicore control cables become essential in creating robust and efficient energy distribution networks. Their capacity to support data and control signals makes them indispensable in modern grid infrastructures.

- Quality Assurance in Cable Manufacturing Maintaining high standards of quality assurance is essential for manufacturers to ensure the reliability and safety of multicore control cables. This involves thorough testing processes and adherence to international standards, crucial for securing client trust and satisfaction.

Image Description