Product Main Parameters

| Parameter | Details |

|---|---|

| Voltage Rating | 300/500V |

| Test Voltage | 4kV |

| Temperature Rating (Fixed) | -40°C to 80°C |

| Temperature Rating (Flexed) | -5°C to 70°C |

| MOQ | 30KM |

| Conductor Material | Class 5 flexible annealed plain copper |

| Insulation | PVC (Polyvinyl Chloride) |

| Armour | Galvanised Steel Wire Braid |

| Sheath | PVC (Polyvinyl Chloride) |

Common Product Specifications

| No. of Cores | Nominal Cross Sectional Area (mm²) | Nominal Thickness of Insulation (mm) | Nominal Thickness of Sheath (mm) | Nominal Overall Diameter (mm) | Nominal Weight (kg/km) |

|---|---|---|---|---|---|

| 2 | 0.75 | 0.4 | 0.8 | 7.2 | 79.3 |

| 3 | 1.0 | 0.4 | 0.8 | 7.9 | 104 |

| 4 | 1.5 | 0.4 | 0.8 | 9.2 | 151 |

| 5 | 2.5 | 0.5 | 1.0 | 12.1 | 266 |

Product Manufacturing Process

Manufacturing control wires involves several processes to ensure quality and reliability. Initially, high-conductivity copper is selected and drawn into thin strands, which are then annealed to enhance flexibility. The strands are twisted to form a conductor, followed by extrusion of PVC insulation. For SY Armored cables, a galvanized steel wire braid is applied for mechanical protection and EMI shielding. The final step involves adding an outer PVC sheath for environmental protection. This meticulous process ensures the wire’s efficiency in various industrial applications.

Product Application Scenarios

SY Armored PVC Control Wires are pivotal in diverse scenarios due to their reliability and efficiency. In industrial automation, they facilitate connection between sensors and controllers, optimizing machine operation. Building management systems utilize them for seamless control of HVAC and lighting. In the automotive sector, these wires are integral for electronic system management. Their shielding capabilities make them ideal for environments with high electromagnetic interference, ensuring robust performance and minimal signal disruptions.

Product After-Sales Service

Our after-sales service includes technical support, installation guidance, and a one-year product warranty. Our team is available to resolve any product-related issues promptly.

Product Transportation

Products are shipped from Ningbo port with standard export packaging, ensuring safe transit. Delivery times vary based on destination and order size.

Product Advantages

- Efficiency: Enables precise signal transmission enhancing machinery operation.

- Reliability: High-quality materials minimize system failures.

- Flexibility: Various specifications adapt to diverse applications.

- Safety: Low-energy signals reduce electrical hazards.

Product FAQ

- What conductor material is used? The control wire features a Class 5 flexible annealed plain copper conductor, known for excellent conductivity and flexibility, preferred by manufacturers.

- Can SY Armored Control Wire be used outdoors? It is suitable for indoor applications in dry, moist, and wet environments, but not recommended for outdoor or underground use.

- What is the minimum bending radius for installation? For fixed applications, the minimum bending radius is four times the overall diameter, while for flexed installations, it is twelve and a half times.

- Are these wires compliant with international standards? Yes, they conform to ISO9001, ISO14001, RoHS, CE, and IEC standards, ensuring quality and reliability.

- What is the MOQ for SY Armored Control Wires? The minimum order quantity is 30KM, allowing manufacturers to manage inventory efficiently.

- What applications are ideal for these wires? SY Armored Control Wires are ideal for machinery, instrumentation, and control equipment, providing reliable signal transmission.

- Is customization available? Yes, we offer OEM services for control wires, allowing manufacturers to meet specific project requirements.

- How is the wire’s performance in harsh environments? With PVC insulation and steel wire braid armor, these wires withstand mechanical stress and EMI in challenging conditions.

- What packaging options are available? Standard export packaging ensures product safety during transit, tailored to specific order requirements.

- How is technical support provided? Our dedicated team offers comprehensive support, including installation guidance and resolving technical issues post-purchase.

Product Hot Topics

- The Role of Control Wire Manufacturers in Industrial Automation Control wire manufacturers like Aston Cable are crucial in modern automation, providing solutions that enhance precision and efficiency in industrial processes. SY Armored Control Wires, manufactured with advanced materials and technology, ensure high performance and reliability in connecting sensors, actuators, and controllers. This connectivity is vital for automated systems to function seamlessly, demonstrating the importance of quality manufacturing in today's technological advancements.

- Why Choose SY Armored Control Wire for Building Management Systems? When selecting control wires for building management systems, manufacturers must consider durability, flexibility, and EMI shielding. SY Armored Control Wires offer these features, ensuring reliable performance in managing HVAC and lighting systems. With robust engineering, these wires are designed to withstand environmental challenges, making them an optimal choice for buildings prioritizing smart system integration and energy efficiency.

- Flexibility and Performance: Key Attributes of SY Armored Control Wire Flexibility and performance are critical in control wire applications. Manufacturers recognize SY Armored Control Wire’s excellence in these areas, enabling intricate installations without compromising signal integrity. The wire’s flexibility allows easy routing in complex setups, while its shielding ensures interference-free operations. These attributes make it an invaluable component in modern technology infrastructure.

- Ensuring Safety with SY Armored Control Wire Safety is paramount in designing control systems, and manufacturers are increasingly turning to SY Armored Control Wires for their low-energy signal transmission. This minimizes electrical hazards, ensuring safe operation across various applications, from industrial automation to building systems. The wire’s compliance with safety standards further solidifies its position as a reliable choice.

- SY Armored Control Wire in the Automotive Industry The automotive industry demands precise control of electronic systems, and manufacturers rely on SY Armored Control Wire for its robust performance. This wire is integral in managing engine functions and electronic controls, ensuring vehicles operate efficiently and safely. Its ability to withstand electromagnetic interference makes it a trusted choice for automotive manufacturers seeking reliable components.

- From Manufacturing to Application: SY Armored Control Wire The journey of SY Armored Control Wire, from manufacturing to application, highlights the meticulous process involved in ensuring quality. Manufacturers utilize advanced techniques to produce wires that meet stringent standards, offering reliability and efficiency in various settings. This commitment to excellence is evident in the wire’s performance in real-world applications.

- Understanding EMI Shielding in Control Wire Design Electromagnetic interference (EMI) can disrupt control systems, and manufacturers address this with SY Armored Control Wire’s steel wire braid armor. This design feature effectively shields against EMI, making it suitable for environments with high electrical noise. Understanding the importance of EMI shielding helps manufacturers select appropriate wires for sensitive applications.

- The Environmental Impact of Control Wire Manufacturing Environmental considerations are integral to modern manufacturing processes. Manufacturers like Aston Cable strive to minimize their environmental footprint while producing high-quality control wires. Compliance with RoHS and ISO14001 standards reflects their commitment to sustainability, ensuring that products like SY Armored Control Wire are both efficient and eco-friendly.

- Customization Options with SY Armored Control Wire Customization is a significant advantage offered by manufacturers like Aston Cable. With OEM services, manufacturers can tailor SY Armored Control Wires to specific project needs, from insulation color to length and specifications. This flexibility allows for precise integration into diverse systems, maximizing efficiency and functionality.

- Advancements in Control Wire Technology Control wire technology continues to evolve, with manufacturers at the forefront of innovation. SY Armored Control Wire exemplifies these advancements, offering improved materials and designs that enhance performance and reliability. As industries adopt new technologies, the role of advanced control wire solutions becomes increasingly crucial, underscoring the importance of continued innovation in this field.

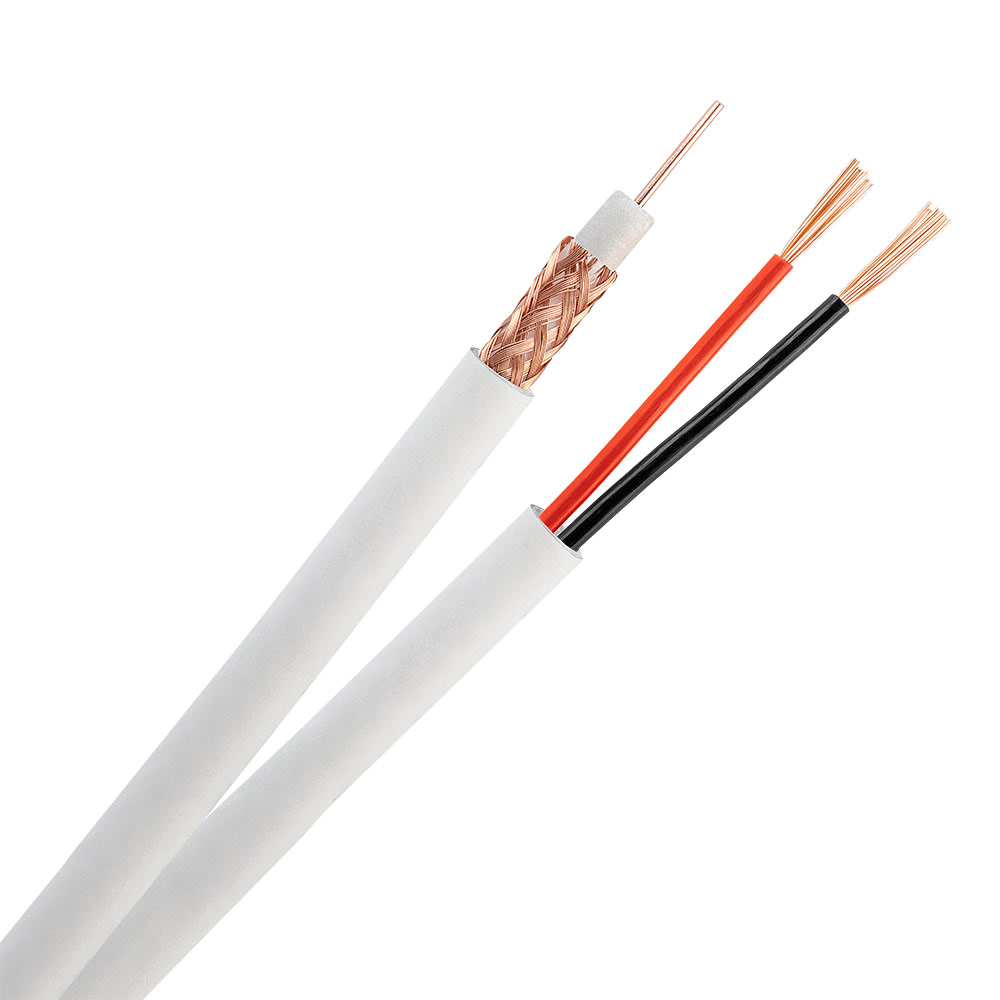

Image Description