Product Main Parameters

| Parameter | Details |

|---|---|

| Conductor | 23AWG Bare Copper |

| Insulation | PVC/LSZH |

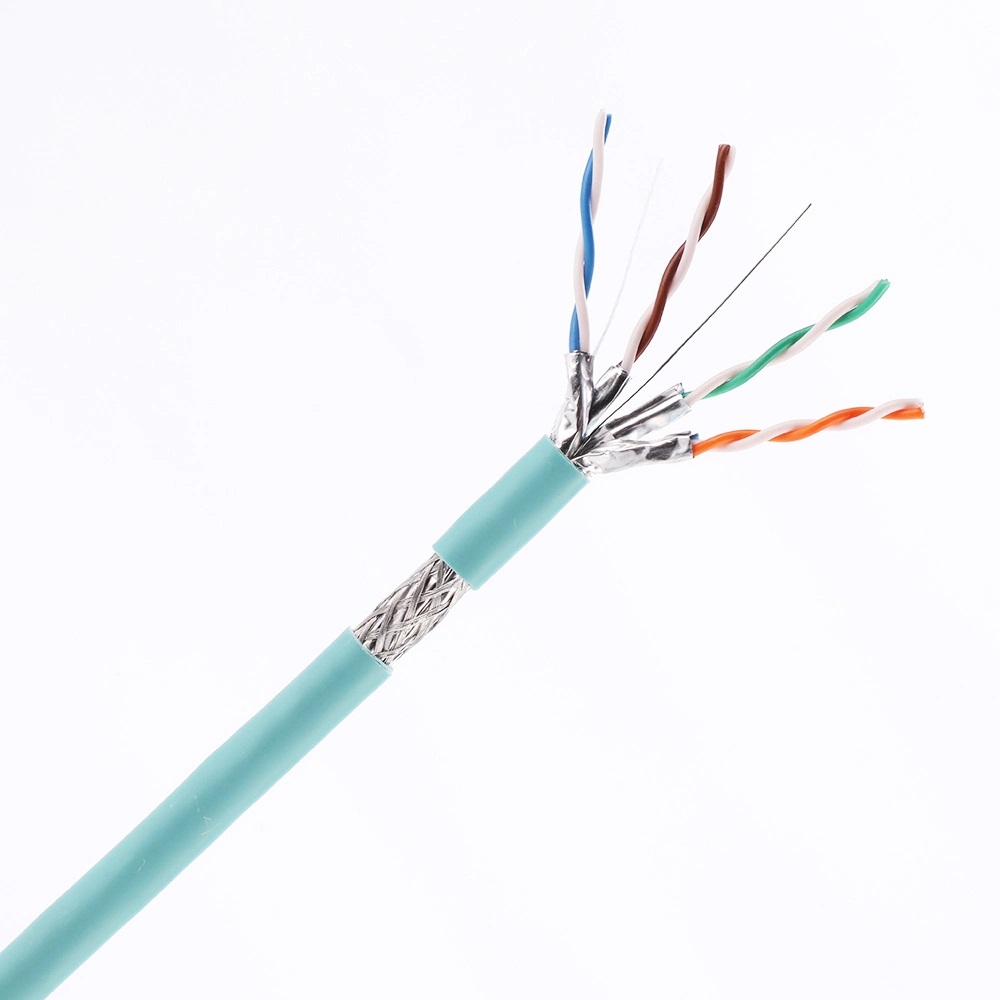

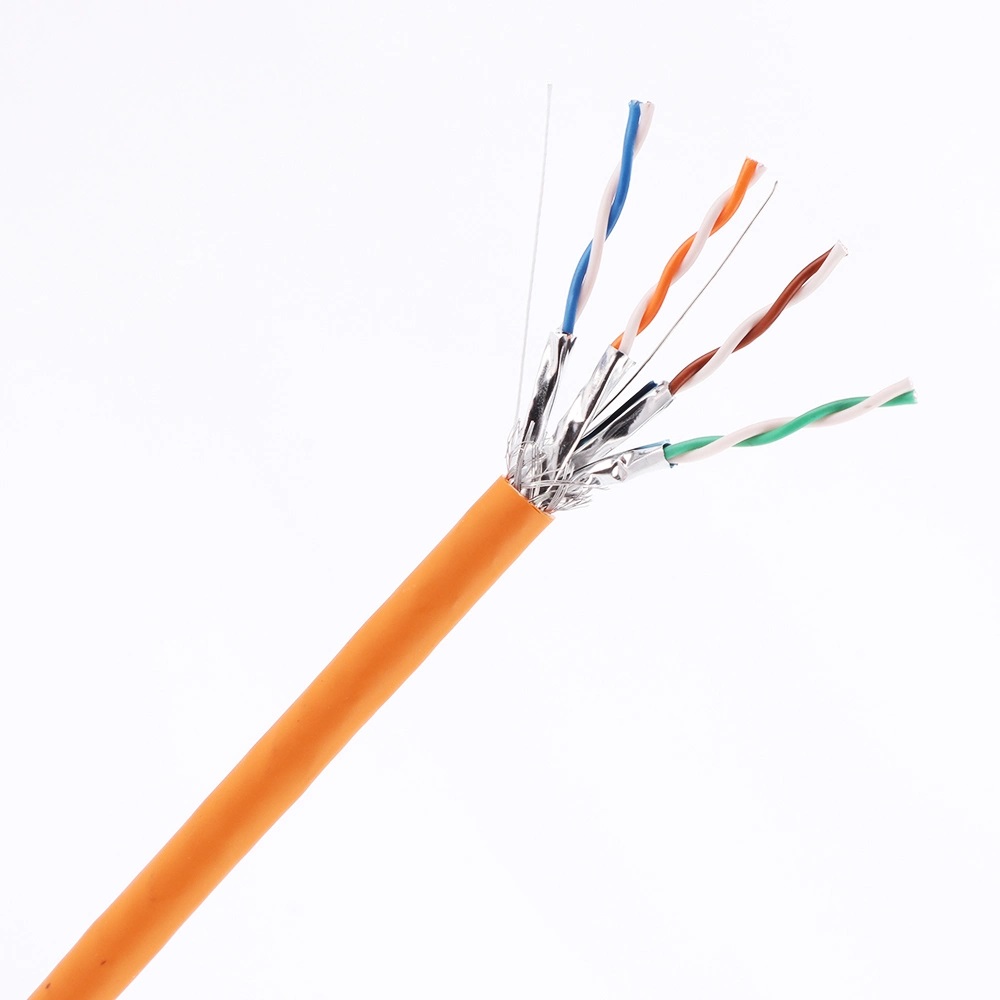

| Shielding | S/FTP |

| Data Rate | 10Gbps |

| Frequency | 600MHz |

Common Product Specifications

| Specification | Details |

|---|---|

| Color | Customizable |

| Certification | CE, RoHS, ISO9001 |

| Length | Custom Lengths Available |

| Braid | Galvanized Steel Wire |

Product Manufacturing Process

SY cables are manufactured through a rigorous process encompassing several stages. Initially, fine strands of high-grade copper are sourced and drawn into the desired conductor size. The copper strands are bundled together to form the conductor. Subsequently, each conductor is insulated using a layer of polyvinyl chloride (PVC), ensuring excellent electrical insulation and mechanical flexibility. The insulated cores are then helically twisted and encased in an inner sheath for additional protection. A layer of galvanized steel wire braid is added for electromagnetic shielding and mechanical protection. Finally, a transparent outer sheath made from PVC is applied, allowing visual inspection while protecting against environmental factors. This comprehensive process, validated by authoritative sources in cable manufacturing, ensures that SY cables deliver unmatched performance in industrial settings.

Product Application Scenarios

SY cables are ideally suited for a variety of industrial applications. Their robust construction, featuring galvanized steel wire braiding, makes them highly resistant to mechanical stress, which is crucial in environments where cables are exposed to potential damage. These cables are commonly used in machinery control circuits, where their flexibility allows them to move with equipment such as robotic arms. Additionally, they are vital in industrial production lines, ensuring the seamless transmission of control signals and low-power requirements. The versatility of SY cables extends to power distribution networks in settings that demand both durability and flexibility. As per findings in industry publications, the adaptability of SY cables to various industrial scenarios underscores their indispensable role in modern manufacturing and automation.

Product After-Sales Service

We offer comprehensive after-sales support for our SY cable products, including technical assistance, troubleshooting, and repair services. Our dedicated team of experts is available to address any queries or issues that arise during installation or use. We ensure that all replacement parts and repairs are carried out promptly to minimize any disruptions. Additionally, we provide a warranty period during which any defects in materials or workmanship will be rectified at no additional cost.

Product Transportation

Our SY cables are securely packaged using industry-standard materials to ensure they arrive in optimal condition. We partner with leading logistics providers to facilitate timely and efficient delivery to your desired location. Whether shipping domestically or internationally, our logistics team prioritizes safe and rapid transport, reducing lead times and ensuring that your project timelines are met.

Product Advantages

- Durability: Galvanized steel wire braid enhances protection against mechanical stress.

- Flexibility: Allows for dynamic movement in industrial applications.

- Conductivity: High-grade copper ensures reliable signal transmission.

- Resistance: Outer PVC sheath guards against environmental factors.

Product FAQ

- What makes SY cables suitable for industrial use? SY cables feature a robust construction with galvanised steel wire braid and flexible PVC insulation, making them ideal for environments with high mechanical stress.

- Can SY cables be used for power distribution? Yes, while primarily used for control signals, they can handle low to medium power distribution in industrial settings.

Product Hot Topics

- How SY Cables Enhance Efficiency in Automation SY cables are integral to automation systems, providing reliable signal transmission and movement flexibility, critical for dynamic machinery operations.

- The Role of SY Cables in Reducing Downtime By offering mechanical protection and electrical reliability, SY cables minimize disruptions in industrial operations, leading to reduced downtime and increased productivity.

Image Description