Product Details

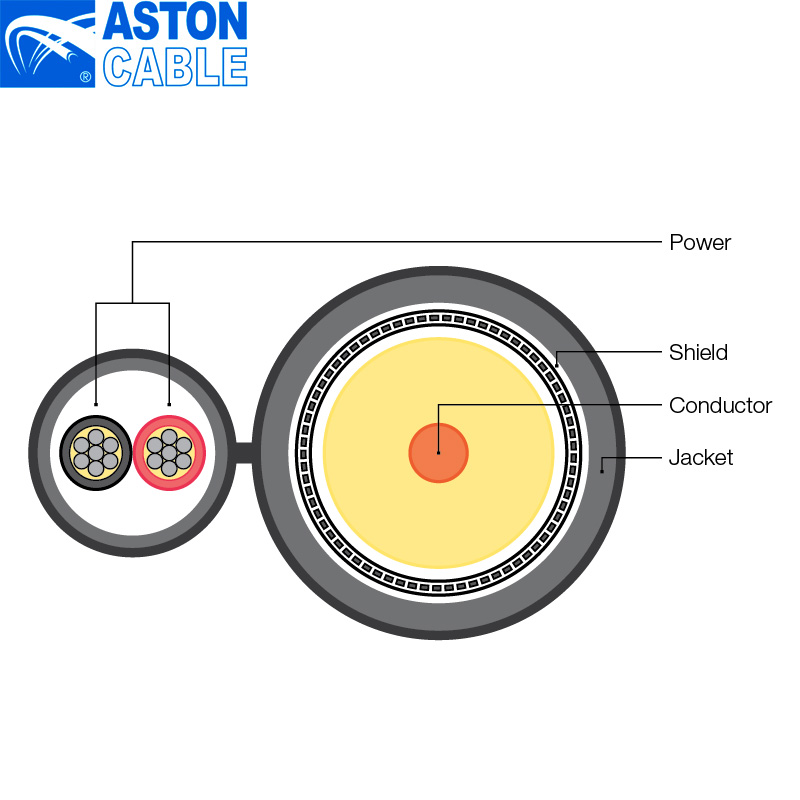

| Parameter | Description |

|---|---|

| Conductor | 1.02mm 18AWG 100% Copper |

| Dielectric | 4.6FPE |

| Jacket | PVC for indoor, Black PE for outdoor |

| Color | Customized |

| Weight | 6.0KG/100m |

| Connector | BNCDC |

Common Product Specifications

| Specification | Details |

|---|---|

| Type | RG6 with power cable |

| Impedance | 75 Ohms |

| Shielding | 90% braid with bonded foil |

Product Manufacturing Process

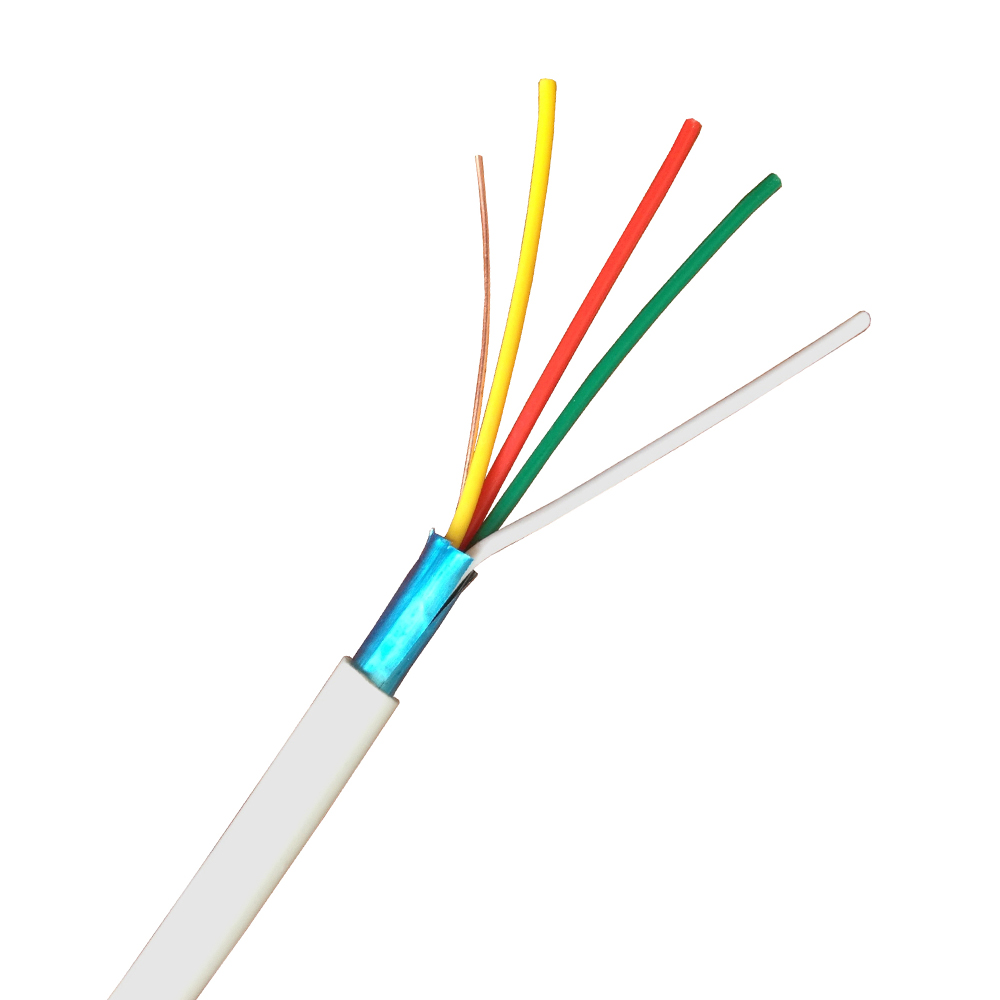

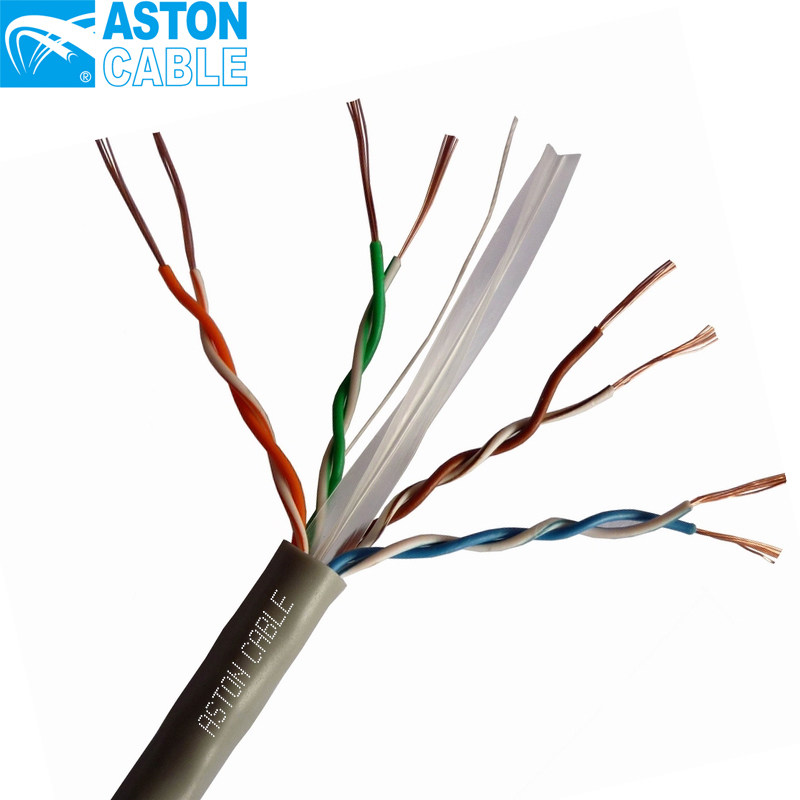

The manufacturing of white coaxial cables involves several critical stages, each ensuring the final product meets high standards for performance and reliability. Initially, the central conductor is drawn from high-purity copper to ensure excellent electrical conductivity. This conductor is then covered with a dielectric insulator, which is typically made from materials such as polyethylene or Teflon. These materials are chosen for their excellent insulating properties and low signal loss characteristics. Next, a metallic shield is braided or wrapped around the dielectric layer to protect the signal from electromagnetic interference (EMI). Finally, an outer jacket made from PVC or PE provides environmental protection and determines the cable's color. Each stage of production is meticulously controlled with advanced machinery and testing equipment to ensure compliance with international standards, such as ISO9001, RoHS, and CE certifications.

Product Application Scenarios

White coaxial cables are integral in various application scenarios, primarily in telecommunications and broadcasting. In the realm of television and satellite transmission, these cables deliver uninterrupted, high-quality audio and video signals, making them indispensable in residential and commercial setups. Additionally, in the internet and networking sector, white coaxial cables facilitate high-speed broadband connections, enabling seamless data transmission over large distances. Furthermore, in radio communications, both amateur and professional, these cables ensure signal clarity by minimizing interference, thus maintaining robust communication links. In security systems, such as CCTV, white coaxial cables efficiently connect cameras to monitoring equipment, providing reliable video feeds essential for surveillance and safety.

Product After-Sales Service

We are committed to ensuring customer satisfaction by offering comprehensive after-sales support. This includes technical assistance for installation and troubleshooting, warranty services, and customer support for operational queries. Our dedicated team of experts is always ready to help with any product-related issues.

Product Transportation

Our white coaxial cables are packaged securely for transportation to prevent any damage during transit. We offer multiple packaging options, such as coil reels, plastic drums, and wooden drums, based on customer requirements. Our logistics team ensures timely delivery through our trusted shipping channels.

Product Advantages

- Immunity to Interference: The robust shielding effectively prevents electromagnetic interference.

- Signal Integrity: Supports high-frequency operations with minimal signal loss.

- Durability: Built to withstand physical and environmental stress.

Product FAQ

- What are white coaxial cables used for?

White coaxial cables are primarily used for transmitting radio frequency signals in applications such as television, internet, and CCTV systems. They are favored for their ability to minimize interference and maintain signal integrity.

- Why are white coaxial cables preferred for indoor use?

White coaxial cables are aesthetically pleasing and can blend with most indoor décors, making them an ideal choice for home and office environments.

- What is the minimum order quantity for these cables?

For our white coaxial cables, the minimum order quantity is 30 kilometers. This ensures adequate supply for most commercial applications.

- What certifications do your white coaxial cables have?

Our cables are ISO9001, RoHS, and CE certified, ensuring they meet international quality and safety standards.

- Can the cable color be customized?

Yes, we offer color customization options for our white coaxial cables to meet specific customer requirements.

- What kind of connector is used with these cables?

Our white coaxial cables typically use BNCDC connectors, which are standard for many applications.

- Are these cables suitable for outdoor installation?

Yes, with appropriate jackets such as black PE, these cables can be used effectively in outdoor installations.

- How should these cables be stored?

These cables should be stored in a cool, dry place to maintain their integrity and prolong their lifespan.

- What is the daily production capacity of your factory?

Our factory has a daily output capacity of 200 kilometers, ensuring we can meet large orders promptly.

- How do you ensure the quality of your cables?

We employ stringent quality control measures during production and use advanced testing equipment to ensure our cables meet all specifications.

Product Hot Topics

- Installation Tips for White Coaxial Cables

When installing white coaxial cables, it is essential to ensure the connectors are securely attached to prevent signal loss. Additionally, routing the cables away from potential sources of electromagnetic interference can enhance performance. For outdoor installations, using appropriate weatherproofing measures can protect against environmental damage.

- Choosing the Right White Coaxial Cable for Your Needs

Selecting the appropriate white coaxial cable involves considering factors such as impedance, frequency range, and environmental conditions. For most residential applications, RG6 cables with good shielding will suffice. However, professional installations may require higher-grade cables to support specific performance requirements.

- Understanding Signal Loss in Coaxial Cables

Signal loss in coaxial cables can occur due to factors like cable length and frequency. Using high-quality materials and ensuring proper installation can mitigate these losses. Regular testing and maintenance can also help maintain optimal signal transmission.

- Customizing Coaxial Cables for Niche Applications

Manufacturers offer customization options for white coaxial cables to suit niche applications. These can include alterations in cable length, color, and connector type to meet specific user requirements, making them versatile for a range of uses.

- The Role of Coaxial Cables in Modern Communication Systems

Despite the rise of wireless technologies, white coaxial cables remain crucial in modern communication systems due to their reliability and performance in transmitting high-frequency signals. They are often the backbone of both domestic and commercial setups.

- Upgrading to High-Performance Coaxial Cables

For homeowners and businesses looking to enhance their communication systems, upgrading to high-performance coaxial cables can provide significant improvements in signal clarity and data transmission speeds, supporting modern high-definition media.

- Environmental Considerations for Coaxial Cable Use

While coaxial cables are robust, environmental factors such as UV exposure and moisture can degrade their performance over time. Choosing cables with appropriate jackets and following best installation practices can mitigate environmental impacts.

- The Future of Coaxial Cables in a Wireless World

Even with the shift towards wireless communication, white coaxial cables continue to offer unmatched performance in specific scenarios. Their role in carrying high-bandwidth signals ensures their relevance in future communication technologies.

- Comparing Coaxial Cables with Fiber Optics

While fiber optics provide higher bandwidth, coaxial cables remain a cost-effective solution for many applications. Understanding the benefits and limitations of each technology can help users make informed installation decisions.

- Maintaining and Testing Your Coaxial Cable Installation

Regular maintenance and testing are essential to ensure coaxial cable installations perform optimally. This involves checking for physical damage, testing signal strength, and replacing any worn or damaged components.

Image Description