For the mechanical and electrical installation industry, wire and cable occupy an important position in the mechanical and electrical installation project, as its main raw material cca copper wire, accounting for 70% to 80% of the total cost of cable products, the price of copper cable with the rise of copper prices and sharp growth, the investor and the construction party in the engineering cost control has brought great difficulties. For this reason, the research and application of copper-clad aluminum cable have increased rapidly.

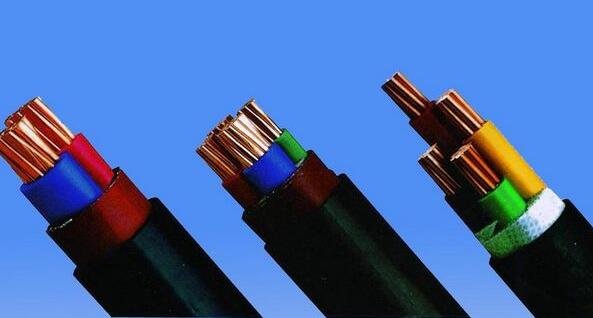

Copper-clad aluminum cable refers to the wire and cable with aluminum core wire instead of copper as the main body of the cable and a certain proportion of copper layer on the outside. In terms of its use, copper-clad aluminum cables can be basically divided into two categories: one is a copper-clad aluminum cable for signal or communication purposes, and the other is a copper-clad aluminum cable for power supply. In terms of its characteristics, the following comparison is made between copper-clad aluminum and pure copper cables.

1. Copper clad aluminum communication cable

Mechanical characteristics:

The strength and elongation of pure copper conductors are larger than that of copper-clad aluminum conductors, which means that pure copper is better than copper-clad aluminum in terms of mechanical properties. From the point of view of copper conductor cable design, the advantages of good mechanical strength of pure copper conductors than copper clad aluminum conductors are not necessarily needed in practical applications. Copper-clad aluminum conductor is much lighter than pure copper, so the overall weight of copper-clad aluminum cable is lighter than pure copper conductor cable, which will bring convenience to the transportation of the cable and the erection and construction of the cable. In addition, copper-clad aluminum is a little softer than pure copper, and cables produced with copper-clad aluminum conductors are better than pure copper cables in terms of softness.

Electrical performance:

Because the electrical conductivity of aluminum is worse than that of copper, the DC resistance of copper-clad aluminum conductors is larger than that of pure copper conductors, and whether this has an impact depends on whether the cable will be used for power supply, such as providing power to amplifiers. When the frequency exceeds 5MHZ, the AC resistance attenuation at this time is not significantly different under the two different conductors. At 5MHZ, the current flows in a thickness of about 0.025 mm near the surface, while the copper layer of the copper-clad aluminum conductor is about twice as thick. For coaxial cables, because the transmitted signal is above 5MHZ, the transmission effect of copper-clad aluminum conductors and pure copper conductors is the same. The attenuation of the cable in the actual test can prove this. Aluminum is softer than pure copper conductors, and it is easy to be straightened in the production process, so to a certain extent, it can be said that the cable with copper clad aluminum is better than the cable with pure copper conductors. Copper clad aluminum is softer than pure copper conductor, and it is easy to straighten in the production process, so to a certain extent, it can be said that the cable with copper clad aluminum is better than the cable with pure copper conductor.

2.copper-clad aluminum power cable

Dc resistivity:

The resistivity of copper-covered aluminum wire is larger than that of pure copper wire, about 1.5 times that of pure copper wire, and the weight of copper-covered aluminum wire is about 1/2 of that of pure copper wire at the same negative value. The use of copper-clad aluminum conductors will play a role in reducing the AC impedance (resistance) generated by higher harmonics. In other applications, by increasing the volume of copper in copper-clad aluminum monwire and corresponding technological measures, the copper-clad aluminum and copper-clad copper composite conductor can meet the conductor DC resistance requirements within the upper limit of the outer diameter size of the existing conductor with the same specification.

Connection method:

The use of copper clad aluminum conductor can meet the current needs of many years of wire and cable in product selection, design, use, installation and other aspects of the habit, but also for the cable terminal compaction, tin welding is beneficial.

Good corrosion resistance:

Aluminum is more corrosive than copper, but because the copper-coated aluminum material has been completely metallurgized, aluminum is completely covered by copper, will not be contacted by water and air, and fully achieve the same performance as copper. Copper clad aluminum/copper clad aluminum conductor is also more conducive to avoid the cable in the long-term use process due to corrosion, collision or due to compaction, tin welding poor contact between the conductor and the terminal, heat caused by the copper layer falling off and the formation of potential difference between the two metals.

Post time: 2024-01-25 14:10:51