Product Details

| Parameter | Specification |

|---|---|

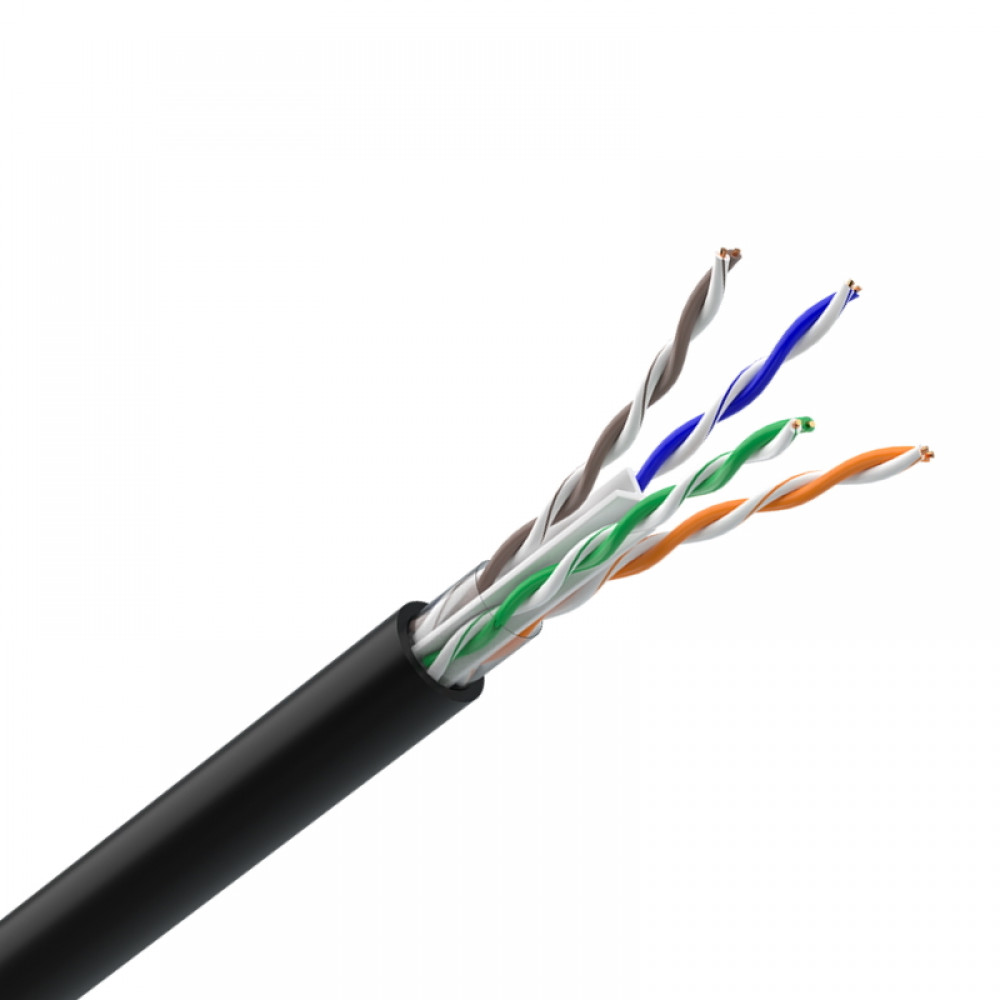

| Conductor | Bare Copper, 23AWG |

| Jacket | PE, with UV resistance |

| Shielding | None |

| Length | 305m per roll |

Common Specifications

| Specification | Details |

|---|---|

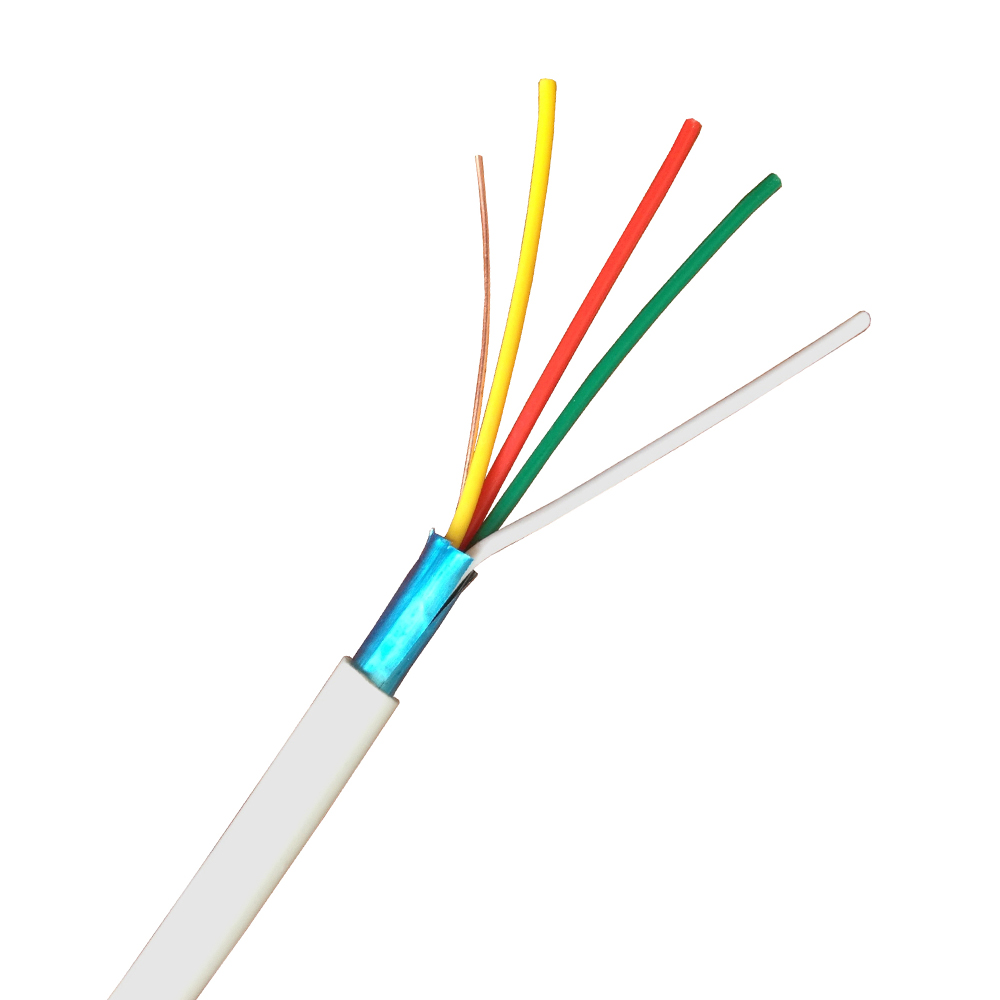

| Material | Copper Clad Aluminum |

| Core | 4 Pairs Stranded |

| Insulation | PE with IEC Retardant |

Manufacturing Process

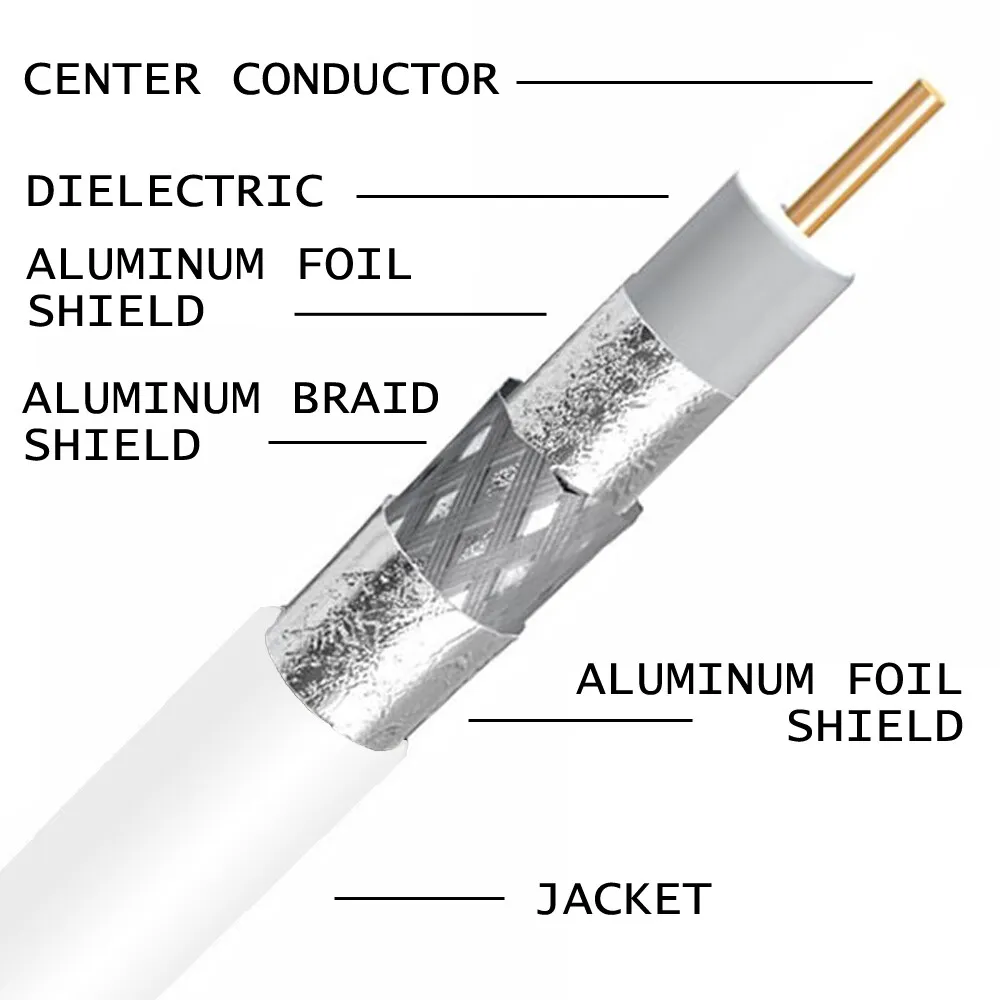

The manufacturing of copper-clad aluminum involves a detailed process where a layer of copper is adhered to an aluminum core through electroplating or thermal bonding. This technique ensures the copper coating's durability and conductivity while keeping the cable lightweight. The adherence process is crucial for maintaining the structural integrity and conductivity, providing a cost-effective solution for long-term use. With advancements in material sciences, the process optimizes copper usage, reducing overall production costs while enhancing cable performance in various applications. Careful quality control measures are implemented at each stage to ensure product reliability and efficiency.

Product Application Scenarios

Copper clad aluminum cables are widely utilized in telecommunications, power distribution, and automotive industries due to their lightweight, cost-effective nature. These cables are ideal for outdoor applications such as CCTV systems, where resistance to environmental factors is necessary. In telecommunications, they facilitate efficient signal transmission without the high cost of pure copper. The automotive industry benefits from these cables in vehicle wiring, contributing to reduced weight and increased fuel efficiency. Their versatile nature makes them suitable for a range of settings, optimizing performance while meeting technical and economic demands.

Product After-Sales Service

Our after-sales service includes technical support, warranty services, and customer assistance for any issues encountered with the cable. Customers can access our service hotline for immediate assistance or refer to our comprehensive online resources, ensuring satisfaction and optimal cable performance.

Product Transportation

The cables are securely packaged to prevent damage during transit. We collaborate with reputable logistics providers to ensure timely and safe delivery to our customers worldwide. Detailed tracking information is provided for transparency and convenience.

Product Advantages

- Cost-effective due to aluminum core

- Lightweight for easy installation

- Durable with enhanced corrosion resistance

- Reliable electrical performance

Product FAQ

- What is copper clad aluminum?

It's a composite material combining aluminum with a copper coating for improved cost-efficiency without sacrificing conductive properties. - Are these cables suitable for outdoor use?

Yes, they feature PE jackets with UV resistance and are designed to withstand harsh environmental conditions. - How does the performance of CCA compare to pure copper?

While not as conductive as pure copper, CCA provides satisfactory performance for most applications at a reduced cost and weight. - What are the main benefits of using CCA in cables?

CCA cables are cost-effective, lightweight, and sufficiently conductive for many applications, making them a versatile choice. - Is there any risk of corrosion?

The copper cladding minimizes the risk of corrosion, offering better durability than aluminum alone. - Can these cables handle high temperatures?

Yes, they are designed to meet IEC retardant standards, making them capable of withstanding various temperature ranges. - What industries use CCA cables the most?

Telecommunications, automotive, and consumer electronics are key industries utilizing CCA cables for their benefits. - What is the MOQ for these cables?

The minimum order quantity is 200 rolls of 305 meters each. - Do you offer customization options?

Yes, color and branding customization are available to suit specific customer needs. - How reliable are the connections with CCA cables?

Proper installation ensures reliable connections; however, attention to detail is necessary to avoid issues over time.

Product Hot Topics

- The Rise of Copper Clad Aluminum in Telecommunications

With increasing demand for cost-effective yet efficient connectivity solutions, manufacturers are turning to copper clad aluminum cables. These cables offer satisfactory performance in data transmission, becoming a popular choice in the telecommunications industry. Their lightweight nature not only reduces shipping costs but also eases the installation process, providing economic and practical benefits. - Environmental Benefits of Using Copper Clad Aluminum

As industries strive for sustainability, copper clad aluminum emerges as an eco-friendly alternative to pure copper. By reducing copper usage without compromising on quality, manufacturers contribute to resource conservation. The lower material costs and improved efficiency align with global trends towards greener production practices. - Innovation in Cable Manufacturing

Manufacturers are constantly innovating to enhance the quality and application of copper clad aluminum cables. Recent advancements have focused on improving the bonding processes, resulting in more durable and efficient cables. This innovation ensures that the products meet the ever-evolving demands of modern technology, remaining competitive in the market. - The Future of Copper Clad Aluminum in the Automotive Industry

The automotive sector is increasingly adopting copper clad aluminum for its lightweight properties, aiding in vehicle weight reduction and fuel economy. Manufacturers recognize the benefits of integrating CCA into vehicle wiring systems, a trend expected to grow as the industry moves towards electric and hybrid solutions. - Comparing Copper Clad Aluminum with Traditional Copper Cables

Manufacturers are offering detailed comparisons to highlight the advantages of CCA over traditional copper cables. While pure copper remains superior in conductivity, CCA provides a balanced compromise in cost and weight, making it suitable for many applications that do not require maximum conductivity. - Challenges in Manufacturing Copper Clad Aluminum

Producing high-quality copper clad aluminum cables involves navigating challenges such as ensuring a durable bond between copper and aluminum. Research and development efforts are focused on overcoming these obstacles, with manufacturers investing in new technologies to enhance production quality. - Customization and Versatility of Copper Clad Aluminum Cables

Manufacturers are offering customization options for copper clad aluminum cables to meet diverse client needs. This versatility allows for a wide range of applications, reinforcing the product's position in various industries. Whether for telecommunications or automotive use, these cables can be tailored for optimal performance. - Misconceptions About Copper Clad Aluminum

Education provided by manufacturers is addressing misconceptions about copper clad aluminum, clarifying its suitability for many applications. Despite perceptions of inferior performance to pure copper, CCA has proven to be effective in many scenarios where cost and weight are prioritized. - Cost-Effectiveness of Copper Clad Aluminum vs. Pure Copper

Financial analysis conducted by manufacturers reveals significant cost savings when choosing copper clad aluminum over pure copper. These savings are critical in large-scale applications where budget constraints play a major role, providing an economical alternative without sacrificing functionality. - Long-Term Durability of Copper Clad Aluminum Cables

Studies and feedback from manufacturers underline the long-term durability of copper clad aluminum cables. With proper maintenance and installation, these cables offer a reliable solution that withstands environmental challenges, proving their longevity and cost benefits over time.

Image Description