Product Main Parameters

| Parameter | Specification |

|---|---|

| Conductors | 23AWG Bare Copper |

| Insulation | PVC, LSZH |

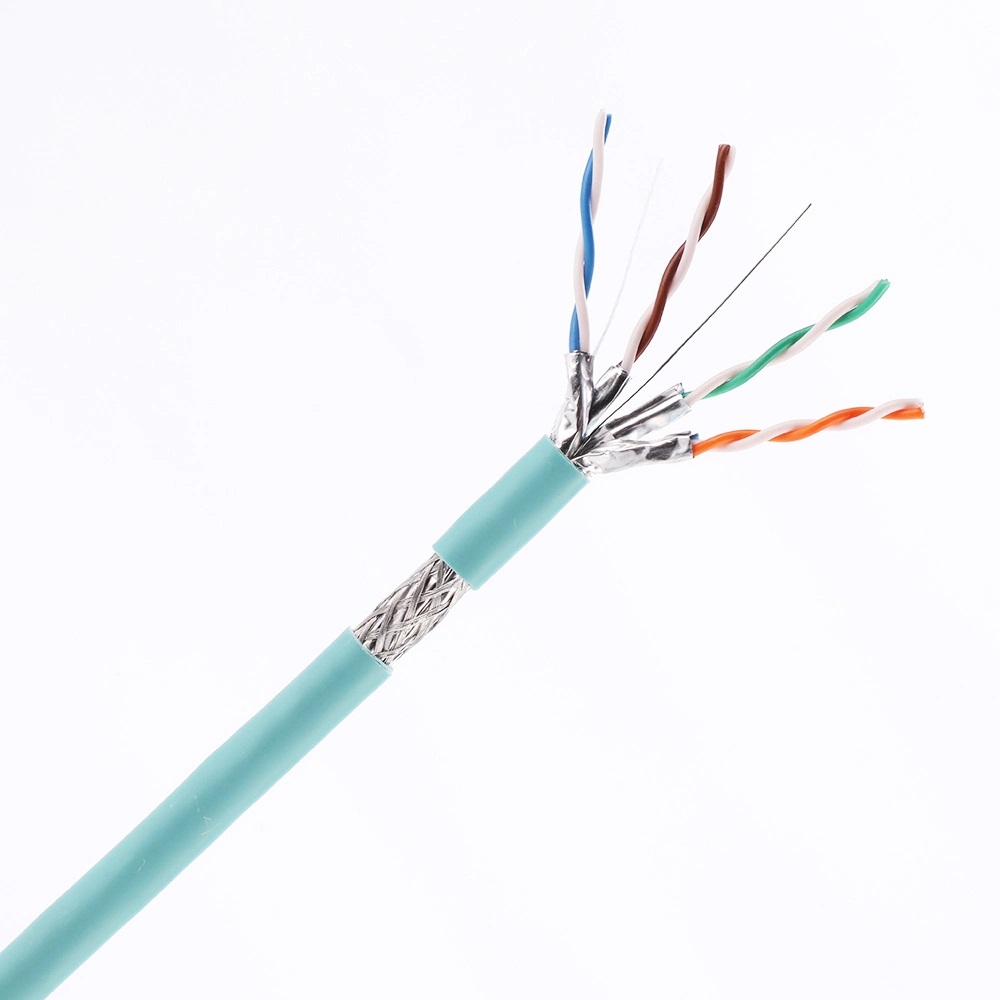

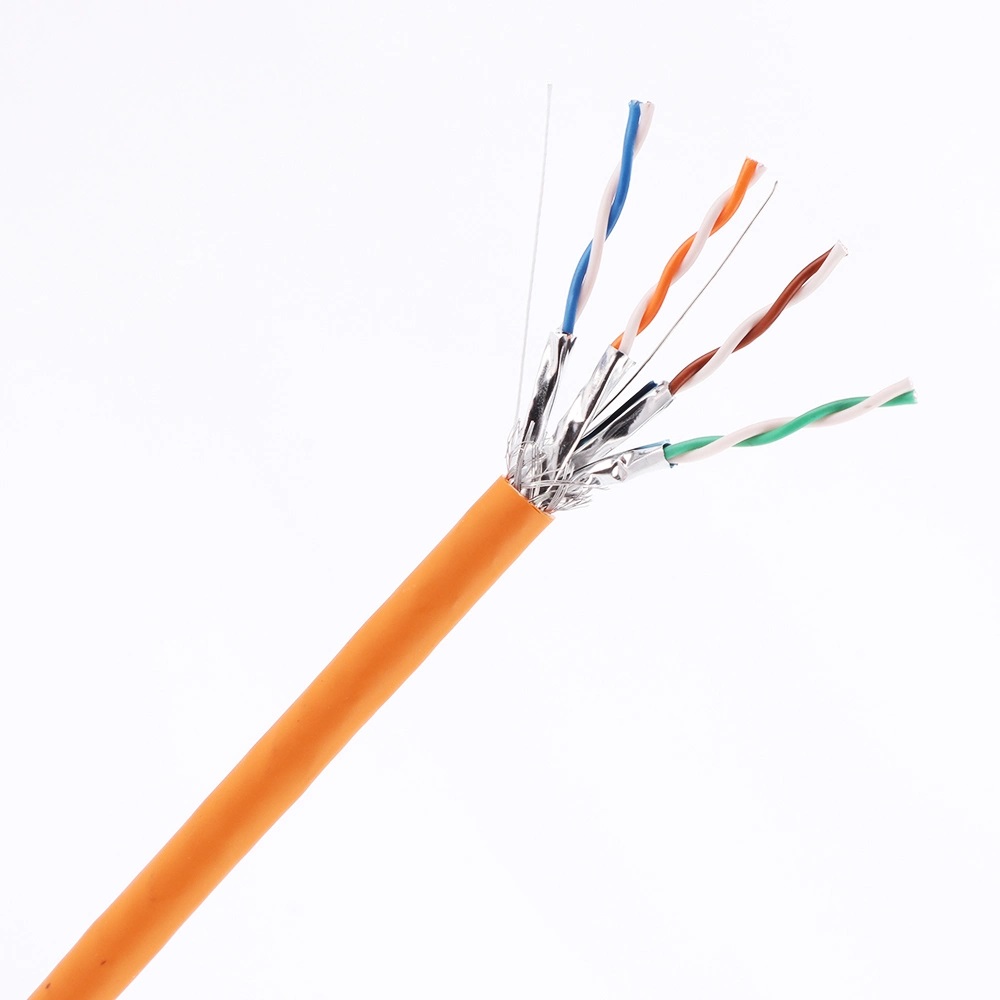

| Shielding | S/FTP structure |

| Bandwidth | 600MHz |

| Data Rate | 10Gbps |

Common Product Specifications

| Specification | Details |

|---|---|

| Jacket Material | PVC, LSZH |

| Origin | Hangzhou, Zhejiang |

| Certification | SGS, CE, ROHS, ISO9001 |

Product Manufacturing Process

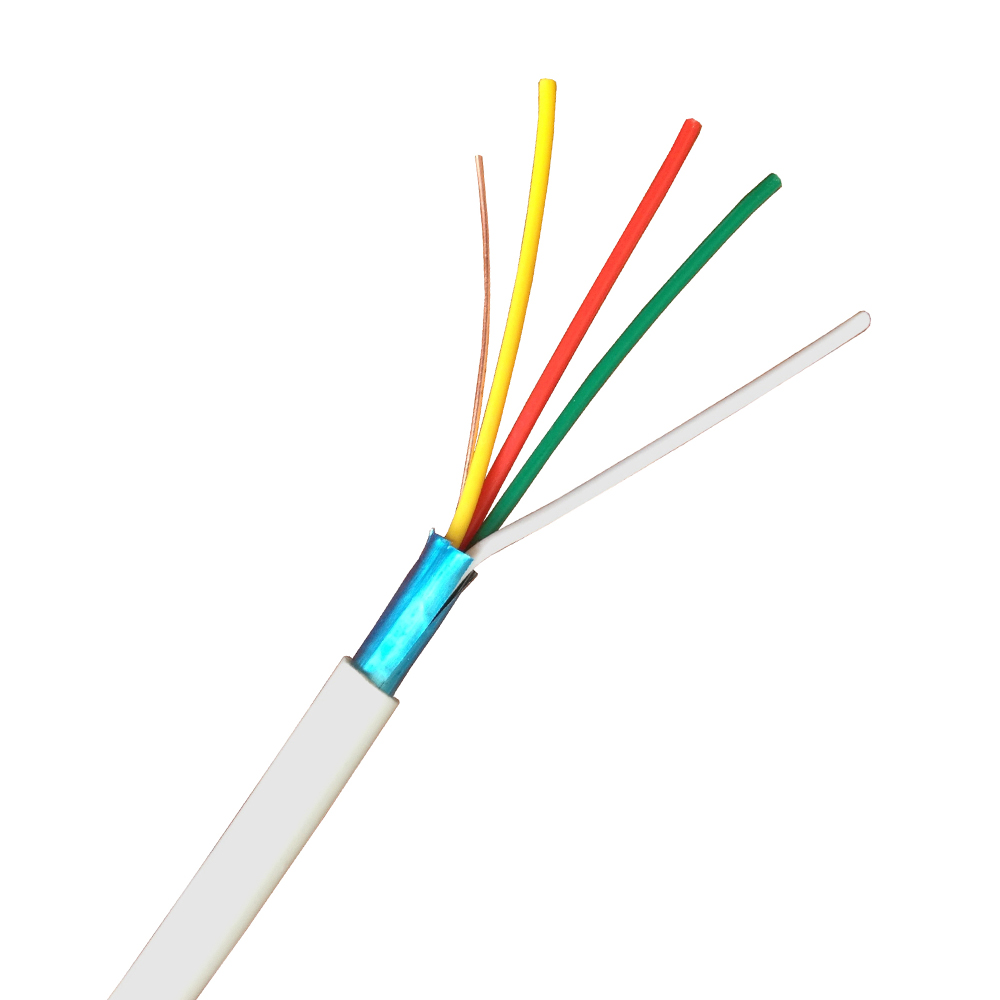

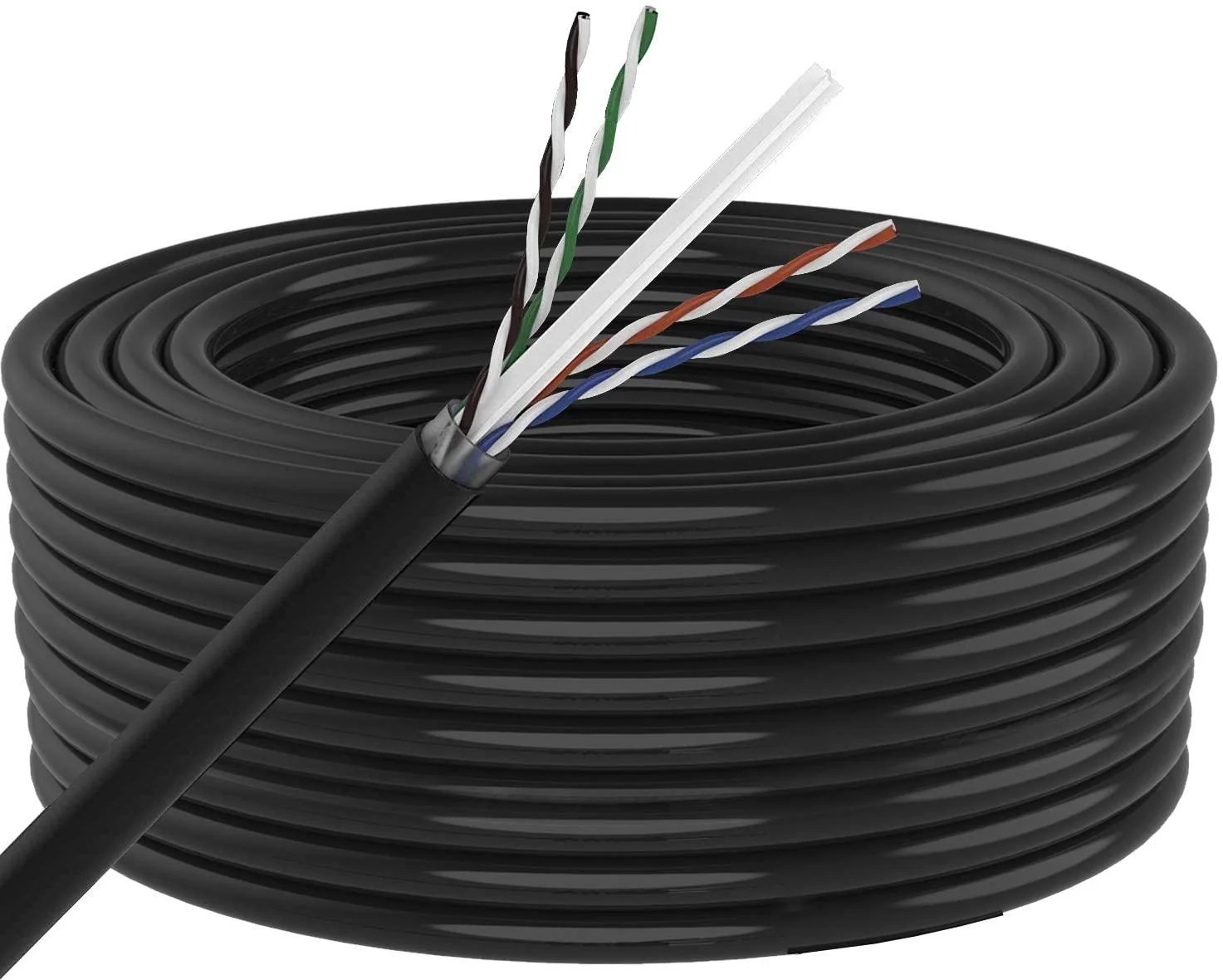

In the domain of communication cable manufacturing, especially for control cables, the process involves several critical stages, each leveraging state-of-the-art technology. Initially, high-grade copper is drawn and annealed to achieve the optimal conductivity required for the conductors. The conductors are then insulated with materials like PVC or LSZH, chosen for their dielectric properties and safety ratings. Subsequently, the cables undergo twisting and shielding to enhance electromagnetic compatibility, ensuring resistance to EMI and RFI. Advanced braiding or foil techniques provide this shielding. The final phase includes jacketing, where a PVC or LSZH outer layer is applied for environmental protection. Rigorous testing for compliance with CE, RoHS, and ISO standards ensures quality and reliability. This process underscores the manufacturer's commitment to safety, performance, and innovation.

Product Application Scenarios

Control cables from esteemed manufacturers are extensively used in various industrial settings. Their primary role is in industrial automation where they connect sensors, actuators, and control systems, ensuring seamless operations in automated production lines. In the energy sector, these cables are pivotal in grid monitoring and substation management, where precision and reliability are paramount. Transportation sectors, such as railways and automotive industries, utilize these cables to manage signaling and communication systems, enhancing coordination and safety. Building management systems also rely on these cables for efficient control of lighting, HVAC, and security systems, reflecting their versatility and indispensability in today's interconnected technological landscape.

Product After-Sales Service

We provide comprehensive after-sales service, ensuring customer satisfaction. Our expert team is available to address any queries or concerns post-purchase, offering technical support to troubleshoot any issues. We also provide a warranty for our control cables, covering manufacturing defects and ensuring replacement or repair when necessary. Our commitment to quality extends beyond the sale, affirming our reputation as a trusted manufacturer.

Product Transportation

Our logistics team ensures the timely and safe delivery of control cables. With strategically located warehouses and efficient supply chain management, we guarantee prompt dispatch from our Ningbo port, ensuring that orders reach our customers without delay. Our packaging is designed to protect the cables during transit, minimizing the risk of damage and maintaining the integrity of the product.

Product Advantages

- Efficiency: Enhances operational processes by providing reliable connectivity.

- Safety: Minimizes the risk of malfunctions in automated systems.

- Durability: Engineered to withstand harsh industrial environments.

- Compliance: Meets international standards for quality and safety.

- Flexibility: Adaptable designs to meet specific industrial requirements.

Product FAQ

- What materials are used in the manufacturing of control cables? Our control cables use high-grade copper for conductors, with insulation made from PVC or LSZH, ensuring excellent conductivity and safety.

- Are these cables resistant to environmental factors? Yes, our control cables are designed to resist moisture, heat, and chemicals, making them suitable for various industrial applications.

- Do the cables meet industry standards? Absolutely. Our cables are compliant with international standards like CE, RoHS, and ISO, ensuring quality and reliability.

- Can the cables be customized? Yes, we offer customization to meet specific customer requirements, including conductor size and jacket material.

- What is the minimum order quantity? The minimum order quantity is 100 rolls, ensuring that we meet both small and large-scale needs.

- How long is the delivery time? Typically, our delivery times range from 2 to 4 weeks, depending on the order size and destination.

- What applications are these cables suitable for? They are ideal for industrial automation, energy management, transportation signaling, and building management systems.

- How does the shielding in control cables work? Our cables use S/FTP shielding, which protects against electromagnetic interference, ensuring signal integrity.

- Do you offer technical support? Yes, we provide full technical support and guidance to assist with installation and operation.

- What warranty do you offer? We offer a comprehensive warranty covering manufacturing defects, ensuring peace of mind for our clients.

Product Hot Topics

- Industrial Automation Connectivity: As manufacturers continue to push the boundaries of automation, control cables play a vital role in maintaining seamless connectivity between machines and systems, driving efficiency and productivity. The precise transmission of data and control signals ensures that operations remain smooth and uninterrupted, highlighting the critical nature of reliable control cables in these environments.

- The Evolution of Control Cable Technology: Recent advancements in cable manufacturing have significantly enhanced the capabilities of control cables. Innovations such as improved shielding mechanisms and insulation materials have increased the durability and performance of these cables, aligning with the evolving needs of various industries. Staying at the forefront of technology, manufacturers are integrating these innovations to deliver superior products.

- Environmental Considerations in Cable Manufacturing: Manufacturers are increasingly focused on producing control cables that adhere to environmental regulations. By utilizing eco-friendly materials and processes that reduce emissions and waste, manufacturers are ensuring that their products not only meet performance standards but also contribute to environmental sustainability.

- Ensuring Compliance with Industry Standards: Meeting international standards such as CE, RoHS, and ISO is imperative for manufacturers. These standards ensure that control cables are safe, reliable, and effective in their applications, providing customers with confidence in their purchases.

- The Impact of 5G on Control Cable Requirements: As 5G technology becomes more prevalent, the demand for control cables capable of handling higher data rates and greater bandwidth has increased. Manufacturers are responding by developing cables that meet these new requirements, ensuring that they remain relevant in the face of technological advancements.

- Customization in Control Cable Manufacturing: The ability to customize control cables to meet specific industry needs is a significant advantage. Manufacturers offer bespoke solutions that cater to unique operational requirements, providing clients with tailored products that optimize performance and efficiency.

- Challenges in Control Cable Production: Manufacturers face challenges such as sourcing high-quality materials and maintaining stringent quality control throughout the production process. Overcoming these challenges is critical to ensuring that control cables meet the high standards expected by customers.

- The Role of Control Cables in Smart Buildings: In the age of smart buildings, control cables are essential for connecting various systems such as lighting, HVAC, and security. These cables facilitate the integration of disparate systems, enabling efficient building management and energy savings.

- Long-Term Trends in Cable Manufacturing: The control cable industry is witnessing trends such as increased focus on sustainability, technological integration, and enhanced performance. Manufacturers are adapting to these trends, ensuring that they deliver products that align with future industry needs.

- Quality Assurance in Cable Manufacturing: Manufacturers implement rigorous quality assurance processes to ensure that every control cable meets the highest standards. From material selection to final testing, each step is carefully monitored to deliver reliable and durable products.

Image Description