Product Main Parameters

| Parameter | Details |

|---|---|

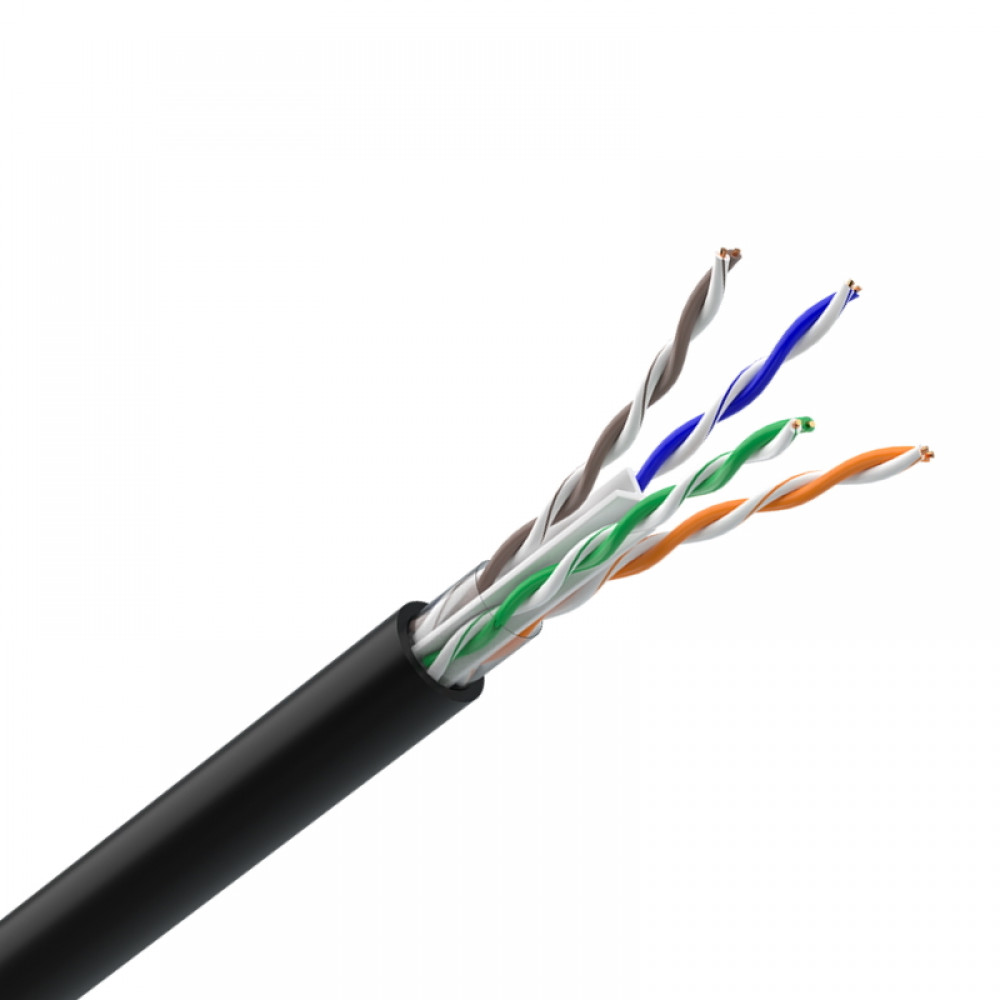

| Conductor | Bare Copper, 23AWG |

| Insulation | PE Retardant |

| Jackets | PE or Double jacket PVC&PE |

| Shielding | None |

| Drain Wire | CCA/BC/TC |

Common Product Specifications

| Specification | Detail |

|---|---|

| Color | Customized |

| Industrial Use | Network data |

| Place of Origin | Hangzhou Zhejiang, China |

| Brand Name | ASTON or OEM |

Product Manufacturing Process

The manufacturing process of multi conductor control cables involves several key steps to ensure reliability and efficiency. The process begins with drawing copper into fine strands, which are then twisted together to form the conductor. Insulation material, such as polyethylene, is then extruded onto the conductors to provide necessary insulation and protection against interference. These conductors are then bundled together and encased in an outer jacket made of materials like PE or PVC, which offers mechanical protection and environmental resistance. Quality control is maintained at every stage to ensure compliance with industry standards such as ISO9001 and RoHS.

Product Application Scenarios

The multi conductor control cable is essential across numerous application scenarios, prominently in industries like manufacturing, building automation, and energy. In industrial automation, these cables connect control units and machinery, facilitating communication for seamless operations. Within smart buildings, they integrate various systems such as HVAC, lighting, and security, enhancing efficiency. In the energy sector, they are vital for linking control devices to monitoring systems, ensuring operational safety and reliability. The versatility and adaptability of these cables to different environments make them indispensable in sophisticated automation systems.

Product After-Sales Service

We offer comprehensive after-sales support, including technical assistance, troubleshooting, and warranty services to ensure customer satisfaction and product reliability.

Product Transportation

All products are shipped using secure, standard export packaging, ensuring the safeguarding of quality during transit. We utilize reliable logistics partners to ensure timely delivery.

Product Advantages

- Flexibility and adaptability to various installations

- Robust design for harsh environments

- Cost-effective solution for complex wiring needs

- High signal integrity and reliability

- Compliance with international standards

Product FAQ

- What materials are used for the insulation?

The insulation typically uses polyethylene, chosen for its excellent insulating properties and resistance to environmental factors.

- Can the cable be customized for specific needs?

Yes, we offer customization options for the jacket color, logo, and other specifications to meet customer needs.

- Is the cable suitable for outdoor use?

Our cables are designed to withstand outdoor conditions, with options for UV resistance and waterproofing.

- What industries commonly use these cables?

Industries such as manufacturing, building automation, and energy frequently utilize these cables for their control needs.

- Are the cables compliant with safety standards?

Yes, our cables comply with international safety and quality standards including ISO9001 and RoHS.

- What is the typical lifespan of these cables?

With proper installation and maintenance, these cables have a long service life, often exceeding several years.

- Do you provide installation support?

We offer detailed installation guidelines and customer support to assist with proper cable installation.

- Can these cables handle high temperatures?

Yes, the materials used can withstand specific temperature ranges, making them suitable for various environments.

- How do I choose the right cable for my application?

Our expert team can assist you in selecting the right cable based on your specific requirements and application type.

- What is the minimum order quantity?

The minimum order quantity for our multi conductor control cables is 200 rolls of 305 meters each.

Product Hot Topics

Why Choose Multi-Conductor Control Cable?

Choosing a multi-conductor control cable ensures reliable transmission of signals and power across various control systems. These cables are designed to withstand environmental challenges while maintaining flexibility and efficiency in installation. The bundled conductor design reduces complexity and cost compared to multiple single-conductor installations.

The Role of Insulation in Multi-Conductor Control Cable

Insulation plays a critical role in the performance of multi-conductor control cables. It provides necessary protection against electrical interference and environmental hazards, ensuring the integrity of the signal transmission. The choice of insulation materials like polyethylene and PVC offers added durability against temperature and chemical exposure.

Key Industries Benefiting from Multi-Conductor Control Cables

Industries such as manufacturing, building automation, transportation, and energy heavily rely on multi-conductor control cables. These cables are integral to control systems, ensuring the seamless operation of machinery, smart building technologies, and monitoring equipment in power plants and other critical infrastructures.

Installation Tips for Multi-Conductor Control Cables

Proper installation of multi-conductor control cables is crucial for optimizing performance and lifespan. Ensure that cables are installed in appropriate environments and secured adequately to prevent mechanical stress. Regular maintenance checks can prevent potential issues and extend the cable's life.

Advancements in Multi-Conductor Control Cable Technology

The technology behind multi-conductor control cables is continually evolving, with advancements focused on improved materials for better insulation, increased durability, and enhanced signal integrity. Innovations in manufacturing processes also contribute to the efficiency and cost-effectiveness of these solutions.

Cost Considerations for Multi-Conductor Control Cables

While multi-conductor control cables can represent a significant upfront investment, their cost-effectiveness in installation and long-term reliability offer substantial savings. Bundling multiple conductors reduces the complexity of wiring, leading to lower labor costs and faster installation times.

Environmental Impact of Multi-Conductor Control Cables

Manufacturers are increasingly focusing on the environmental impact of multi-conductor control cables. The use of recyclable materials and compliance with environmental standards such as RoHS reflects a commitment to reducing ecological footprints.

Choosing the Right Jacket Material

The choice of outer jacket material significantly affects the performance of a multi-conductor control cable. Considerations include resistance to UV radiation, moisture, and chemicals. Options like PE and PVC offer different benefits, depending on the application environment.

Understanding Shielding Requirements in Control Cables

While some multi-conductor control cables do not include internal shielding, certain applications may require additional protection against electromagnetic interference. Understanding the level of shielding needed for your specific application can help in selecting the right cable.

Future Trends in Multi-Conductor Control Cable Design

Future trends in multi-conductor control cable design focus on enhancing performance through advanced materials and sustainable manufacturing practices. As technology progresses, the integration of smart features in cables could further enhance their role in sophisticated control systems.

Image Description