Product Main Parameters

| Parameter | Details |

|---|---|

| Conductor Material | Bare Copper/CCA |

| Insulation | HDPE |

| Outer Jacket | PVC & PE |

| Cable Type | CAT5E U/UTP |

| MOQ | 50KM |

Common Product Specifications

| Specification | Details |

|---|---|

| Daily Output | 200KM |

| Supply Ability | 25,000KM/Year |

| Delivery Port | Ningbo |

Product Manufacturing Process

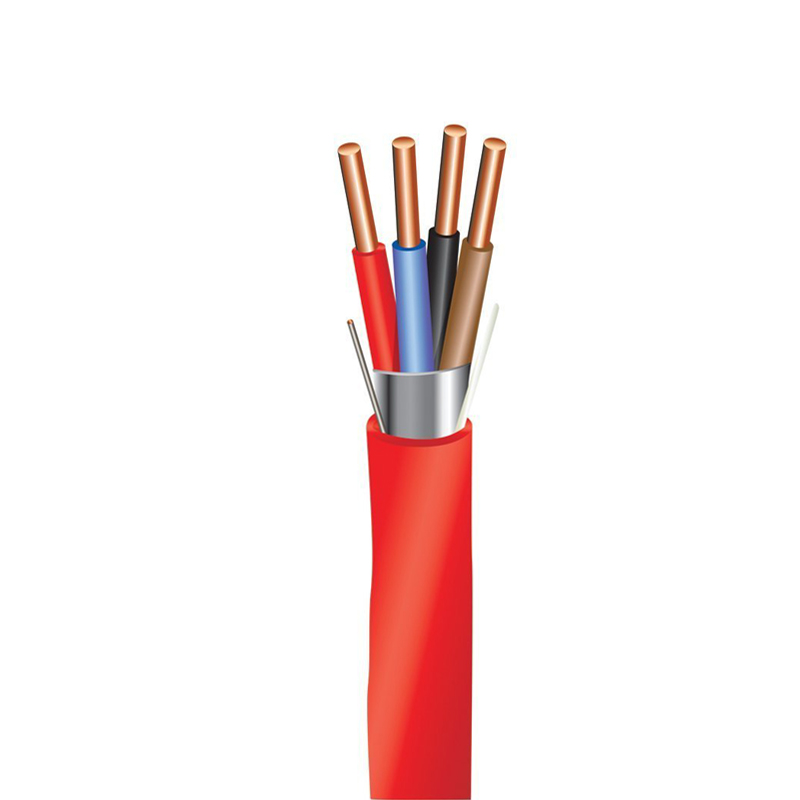

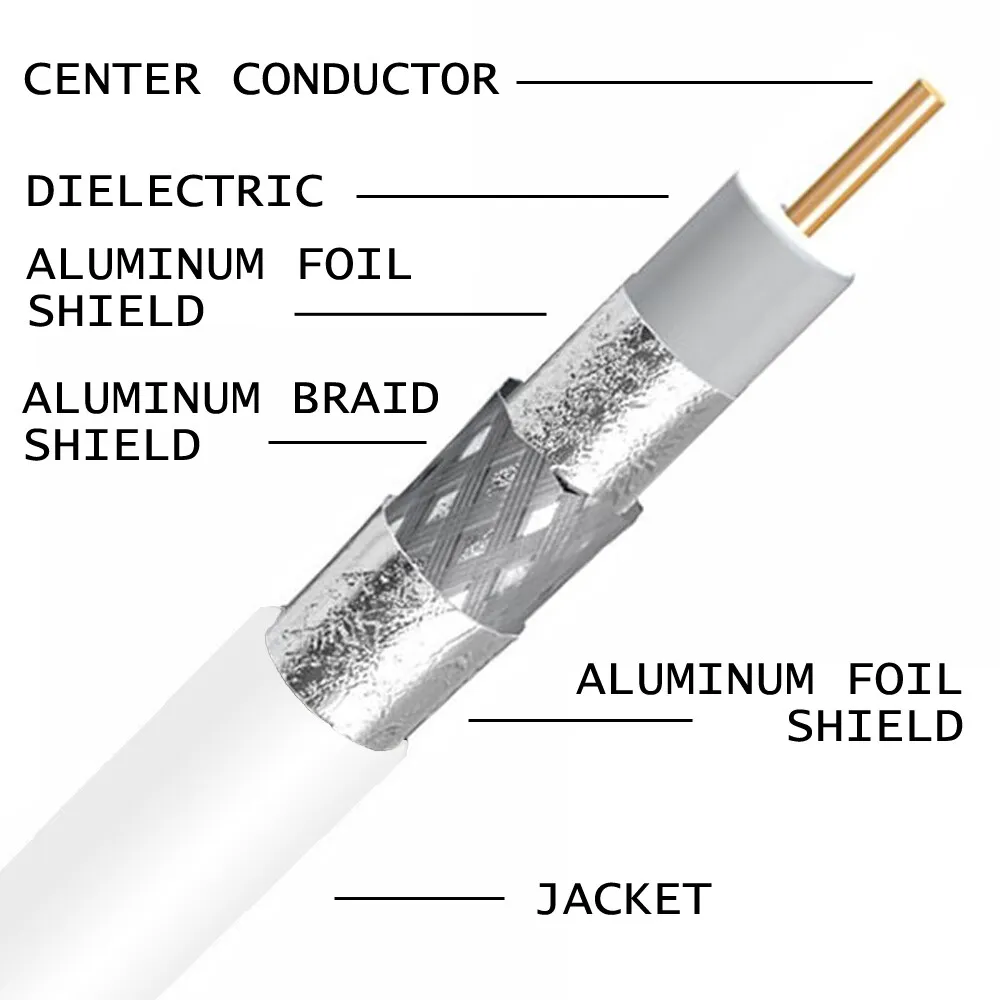

Based on current authoritative manufacturing literature, the process of producing door access cables involves multiple stages, including conductor preparation, insulation application, shielding (if applicable), and jacket layering. Initially, the copper or CCA conductors are prepared and drawn into specified thicknesses. These conductors are then insulated using materials like HDPE to ensure electrical safety and prevent interference. In cases where the cable requires EMI protection, an additional shielding layer, such as braided or foil shielding, is applied. Finally, the prepared core is encased in double jackets made of PVC inside and PE outside. This ensures the cable’s durability, UV resistance, and suitability for outdoor installations.

Product Application Scenarios

Door access cables are vital in various sectors, each demanding specific security solutions, as highlighted in recent studies. In commercial buildings, these cables integrate with sophisticated access systems to manage large-scale entry, often working in tandem with building management systems. In industrial sectors, these cables secure sensitive zones, ensuring compliance with safety protocols and enduring harsh conditions. Meanwhile, in residential complexes, door access cables facilitate advanced security features, such as keyless entry, enhancing both safety and convenience for residents. Authoritative sources emphasize the adaptability of these cables in meeting diverse environmental and security challenges.

Product After-Sales Service

We offer comprehensive after-sales support, including technical assistance, warranty services, and replacement solutions for defective products. Our dedicated team ensures prompt response and resolution of any cable-related issues to maintain optimal system performance and customer satisfaction.

Product Transportation

The cables are packed using normal export packaging standards to ensure safe and secure delivery. Our logistics team ensures timely shipping to your location from Ningbo port.

Product Advantages

- Double jackets for enhanced UV protection

- High electrical conductivity

- Durability and corrosion resistance

- Easy installation and maintenance

- Flexible MOQ of 50KM allowing for scalability

Product FAQ

- What makes the double jackets beneficial for outdoor use?

As a manufacturer of door access cables, our double jackets provide superior UV resistance and mechanical strength. The outer PE layer offers enhanced protection against environmental elements, making the cables ideal for outdoor applications.

- Why choose PVC inside and PE outside?

The combination of PVC and PE provides optimal protection and flexibility. PVC is softer and more suitable for indoor twisting needs, while the PE layer ensures outdoor durability.

- Are these cables suitable for residential use?

Yes, our door access cables are designed to support security systems in residential complexes, offering enhanced safety features such as smartphone-controlled access.

- Can you customize the cable color?

Yes, as a manufacturer, we offer color customization options according to your requirements to match the environmental aesthetics or brand identity.

- What is the typical lead time for an order?

We strive to offer a turnaround of 2-4 weeks from order placement to delivery, depending on order size and customization requirements.

- How do you ensure cable quality?

We adhere to strict quality control systems and ISO standards, maintaining product excellence throughout the manufacturing process. Our cables are RoHS and CE compliant.

- Is bulk purchasing available?

Yes, we support bulk purchasing with competitive pricing for larger volumes, catering to various project requirements efficiently.

- How do these cables handle EMI?

Our door access cables are available with optional shielding to protect against electromagnetic interference, ensuring reliable data transmission in industrial settings.

- What is the warranty period?

Our products come with a comprehensive warranty period, ensuring support for any defects or issues arising from manufacturing faults.

- How eco-friendly are your cables?

We are committed to environmental sustainability. Our manufacturing processes comply with ISO14001 standards, and our products are designed to minimize environmental impact.

Product Hot Topics

- Emerging Trends in Door Access Cable Manufacturing

As a leading manufacturer, we consistently explore new technologies and materials to enhance door access cable performance. Currently, the integration of eco-friendly materials and advanced data handling capabilities are at the forefront of innovation. This ensures not only improved security systems but also alignment with global environmental standards.

- Importance of UV Resistance in Outdoor Cables

UV resistance is critical for outdoor cables to prevent degradation over time. Our cables feature a PE outer layer, renowned for its UV stability and protection against harsh elements, making them a reliable choice for long-term installations.

- Advancements in Cable Sheathing Technology

Cable sheathing technology has progressed significantly, offering better insulation and protection. Our use of double jackets, combining PVC and PE, provides an exemplary balance of flexibility and robustness, ideal for diverse applications.

- Cost-Effectiveness of Our Double Jacketed Cables

While the dual-layer design incurs a slightly higher production cost, the resultant durability and extended cable lifespan offer significant savings on repairs and replacements in the long term, making them a cost-effective choice.

- Customizing Door Access Cables for Varied Needs

Customization is key in meeting specific project demands. As a manufacturer, we offer tailored solutions, from conductor materials to color coding, enabling a perfect fit for unique security setups.

- Ensuring Data Integrity in Security Systems

Reliable data transmission is crucial for any security system. Our cables are engineered to minimize interference and signal loss, maintaining system integrity and security.

- The Role of Door Access Cables in Smart Buildings

In the era of smart buildings, door access cables are integral in connecting IoT devices, ensuring seamless communication and security within integrated systems.

- Environmental Considerations in Cable Manufacturing

We prioritize sustainable practices in our manufacturing processes, ensuring that our door access cables meet environmental standards and contribute to a greener planet.

- Challenges in Installing Outdoor Access Cables

Outdoor installations require careful planning to avoid exposure to harsh conditions and interference. Our cables are designed to withstand such challenges, offering reliable performance.

- Future of Security Infrastructure with Advanced Cabling

The future of security systems lies in robust cabling solutions that adapt to technological advancements. As a manufacturer, we are committed to pioneering these innovations to enhance security infrastructure globally.

Image Description