Product Details

| Parameter | Specification |

|---|---|

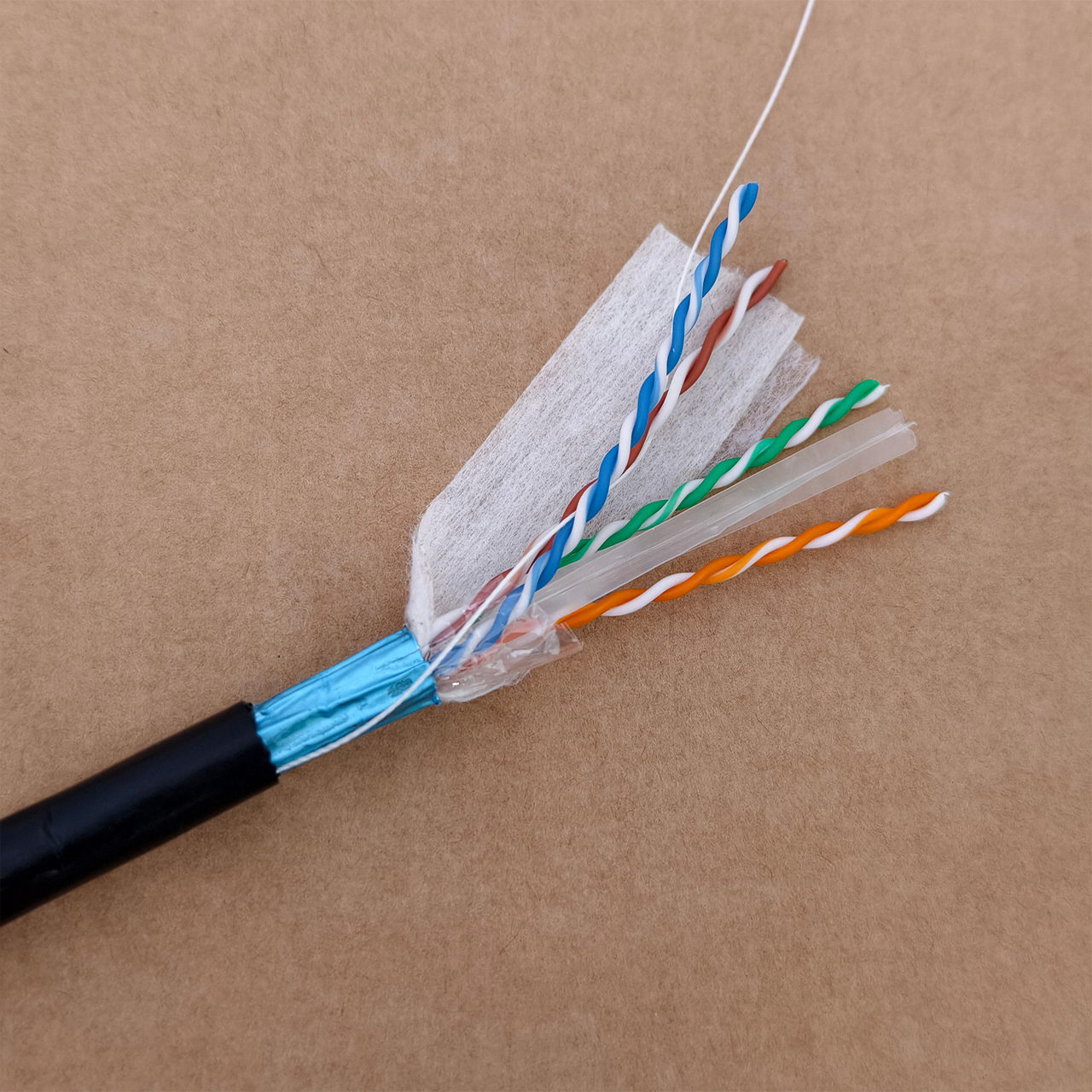

| Conductor | 1.02mm 100% Copper |

| Dielectric | 4.6FPE |

| Jackets | PVC (indoor), Black PE (outdoor) |

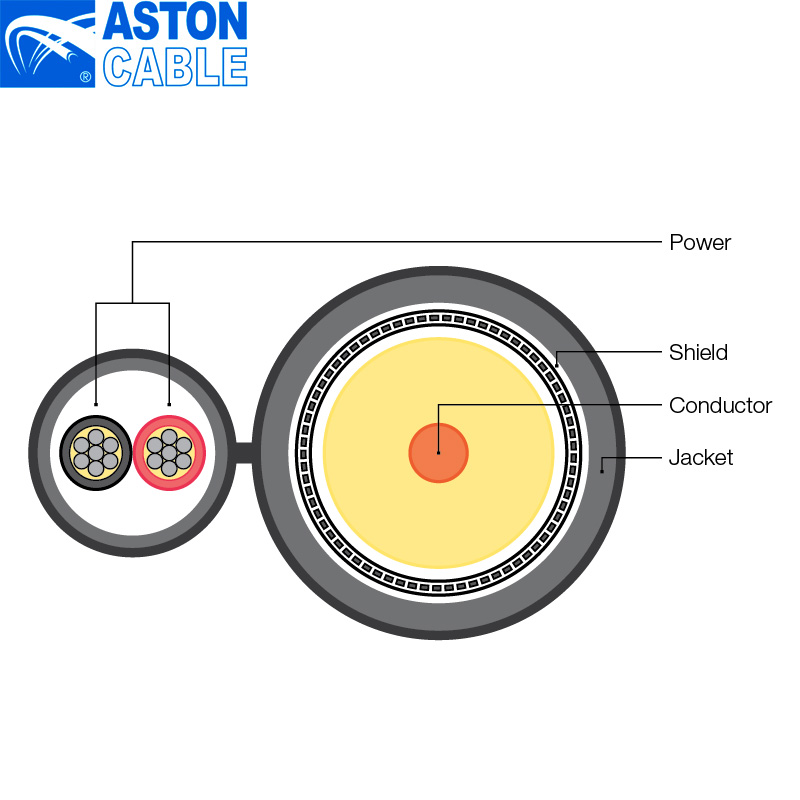

| Power Cable | 2 Stranded 18AWG 7x0.37mm Black/Red |

| Color | Customized |

Common Product Specifications

| Feature | Description |

|---|---|

| Type | RG6 with power cable |

| Weight | 6.0KG/100m |

| Braid | 90% coverage with bonded foil shield |

| Usage | CCTV, Video, Broadband Internet |

Product Manufacturing Process

According to a recent paper on cable manufacturing processes, CCA wire manufacturing involves bonding a high-purity copper layer to an aluminum core. Using methods such as electroplating or metallurgical bonding ensures strong adhesion. This process reduces copper usage while preserving conductivity. Electroplating provides a uniform copper layer, while metallurgical bonding ensures mechanical strength, making CCA wire a suitable choice for telecommunications where cost is a concern.

Product Application Scenarios

CCA wire in RG6 coaxial cables is widely used in telecommunications and video applications, as referenced in industry papers. These cables are ideal for CCTV surveillance, satellite, and broadband internet installations, where the balance of cost, conductivity, and weight is crucial. The copper layer enhances conductivity, while the aluminum core maintains affordability, making these cables preferred in budget-conscious projects without compromising performance.

Product After-Sales Service

Aston Cable provides comprehensive after-sales service, including technical support and a warranty for manufacturing defects. Our team ensures prompt response times to resolve any issues, guaranteeing customer satisfaction.

Product Transportation

Our products are shipped using reliable logistics partners, ensuring safe and timely delivery. Packaging options include coil reels, plastic drums, wooden drums, and carton boxes suitable for export standards.

Product Advantages

- Cost-efficient design using CCA wire

- Lightweight and easy to install

- Good balance of flexibility and strength

- Corrosion-resistant for extended lifespan

Product FAQ

- What makes CCA wire cost-effective?

CCA wire uses less copper by having an aluminum core, cutting material costs while maintaining conductivity, which makes it attractive for budget-conscious projects.

- Is CCA wire suitable for high-frequency applications?

While CCA wire is suitable for many applications, pure copper may be necessary for maximum conductivity in very high-frequency scenarios.

- How does CCA wire compare to pure copper in terms of weight?

CCA wire is lighter than pure copper due to its aluminum core, making it easier to handle and install, particularly beneficial in industry applications like automotive and aerospace.

- Can CCA wire be used in all building codes?

No, CCA wire may not meet all building codes, particularly where pure copper is required for specific safety and reliability standards. Always check local regulations.

- What are the environmental conditions CCA wire can withstand?

The copper coating provides protection against corrosion, extending its lifespan even in adverse environmental conditions.

- What are the packaging options for CCA wire?

CCA wire can be packed in coil reels, plastic drums, wooden drums, color boxes and carton boxes, all compliant with standard export packaging norms.

- Is the CCA wire RoHS compliant?

Yes, our CCA wire is RoHS compliant, ensuring it meets all relevant safety and environmental regulations.

- Can I order customized colors for the jackets?

Yes, we offer customized color options for the jackets to meet specific customer requirements or branding needs.

- What's the minimum order quantity for CCA wire?

The minimum order quantity for our CCA wire is 30 kilometers, allowing for large scale projects and commercial supply.

- How does the delivery process work?

Our reliable logistics partners ensure timely deliveries with tracking options provided for order convenience and transparency.

Product Hot Topics

- Advantages of CCA wire in Coaxial Applications

CCA wire's cost efficiency and reduced weight make it an excellent material for coaxial applications, delivering reliable performance at a fraction of the cost of pure copper. Many suppliers highlight its ease of installation and long-lasting corrosion resistance, appealing to industries such as telecommunications and automotive looking for cost-effective solutions without sacrificing quality.

- Is CCA Wire the Future of Cable Manufacturing?

Suppliers are increasingly leaning towards CCA wire due to the rising copper prices and demand for lighter materials. While CCA cannot replace pure copper in high-conductivity applications, advancements in bonding techniques improve its performance, making it a viable option in many scenarios, likely securing its place in future cable manufacturing trends.

- Environmental Impact of CCA Versus Copper

With sustainability becoming a critical factor, suppliers are evaluating the environmental footprint of CCA wire against that of copper. CCA wire, with its less intensive copper use, presents a lesser environmental impact, aligning with the growing push towards eco-friendly practices in manufacturing and infrastructure development.

- The Role of CCA Wire in Telecom Infrastructure

As telecom infrastructure expands, suppliers find CCA wire advantageous for reducing costs while maintaining adequate conductivity for data transfer. Its application in CCTV and broadband internet installations demonstrates its utility, especially in remote or large-scale installations where cost is a critical factor.

- Challenges Facing CCA Wire Acceptance

Despite its benefits, suppliers face challenges in gaining full acceptance of CCA wire due to building codes and industry regulations that favor pure copper. Ongoing discussions and studies aim to address these concerns, fostering broader acceptance and usage of CCA wire in diverse applications.

- How CCA Wire Suppliers Ensure Quality

Quality assurance is a top priority for CCA wire suppliers. Rigorous testing and certification processes, such as RoHS and ISO compliance, ensure that the products meet international standards, providing confidence in their application across various industries.

- Innovations in CCA Wire Production

Suppliers are constantly innovating to improve CCA wire production processes. Advances in metallurgical bonding techniques and electroplating have enhanced the strength and conductivity of CCA wire, allowing it to serve more demanding applications and broadening its market appeal.

- Cost-Saving Strategies with CCA Wire

For projects with tight budgets, suppliers recommend integrating CCA wire into cable systems. By substituting pure copper with CCA where applicable, companies can achieve significant cost reductions without compromising on essential performance metrics, making it an attractive option for large-scale deployments.

- Frequently Asked Questions About CCA Cable

Suppliers address common inquiries, offering insights into the construction, benefits, and limitations of CCA wire. By clarifying these aspects, they help customers make informed decisions, ensuring that CCA wire is used effectively and appropriately within their projects.

- Comparing CCA Wire to Other Conductive Materials

Suppliers often compare CCA wire to other conductive materials to demonstrate its advantages. The balance of cost, weight, and sufficient conductivity positions CCA wire favorably against more expensive or heavier alternatives, especially when full copper's conductivity isn't a prerequisite.

Image Description