Product Details

| Specification | Details |

|---|---|

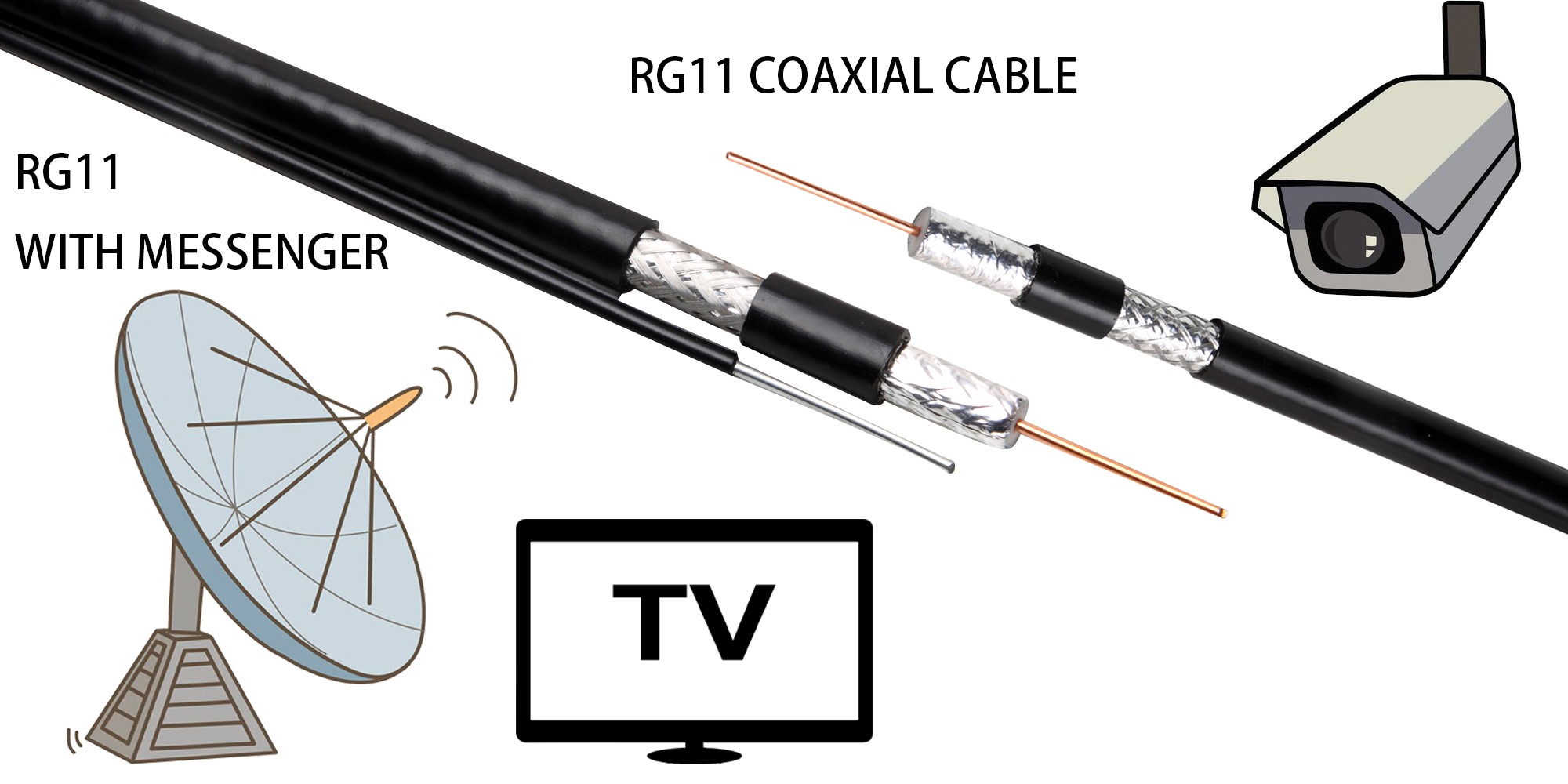

| Product Name | RG11 Coaxial Cable |

| Jackets | PVC, PE |

| Color | Black |

| Conductor | 1.63mm 14AWG |

| Usage | Data transmission cable |

| Origin | Hangzhou Zhejiang |

| Capacitance | 52.493 pF/m | 16 pF/ft |

| Characteristic Impedance | 75 ohm |

| Nominal Velocity of Propagation (NVP) | 84% |

Product Manufacturing Process

The manufacturing of RG11 CCAM wire involves a sophisticated process that combines the mechanical properties of copper, aluminum, and magnesium. The aluminum core is first clad with copper and a trace of magnesium to improve tensile strength and conductivity. This multi-layer composition is then heat-treated and cooled to ensure a strong bond between the materials. Rigorous testing is conducted throughout the production cycle to maintain high standards of quality and performance.

Product Application Scenarios

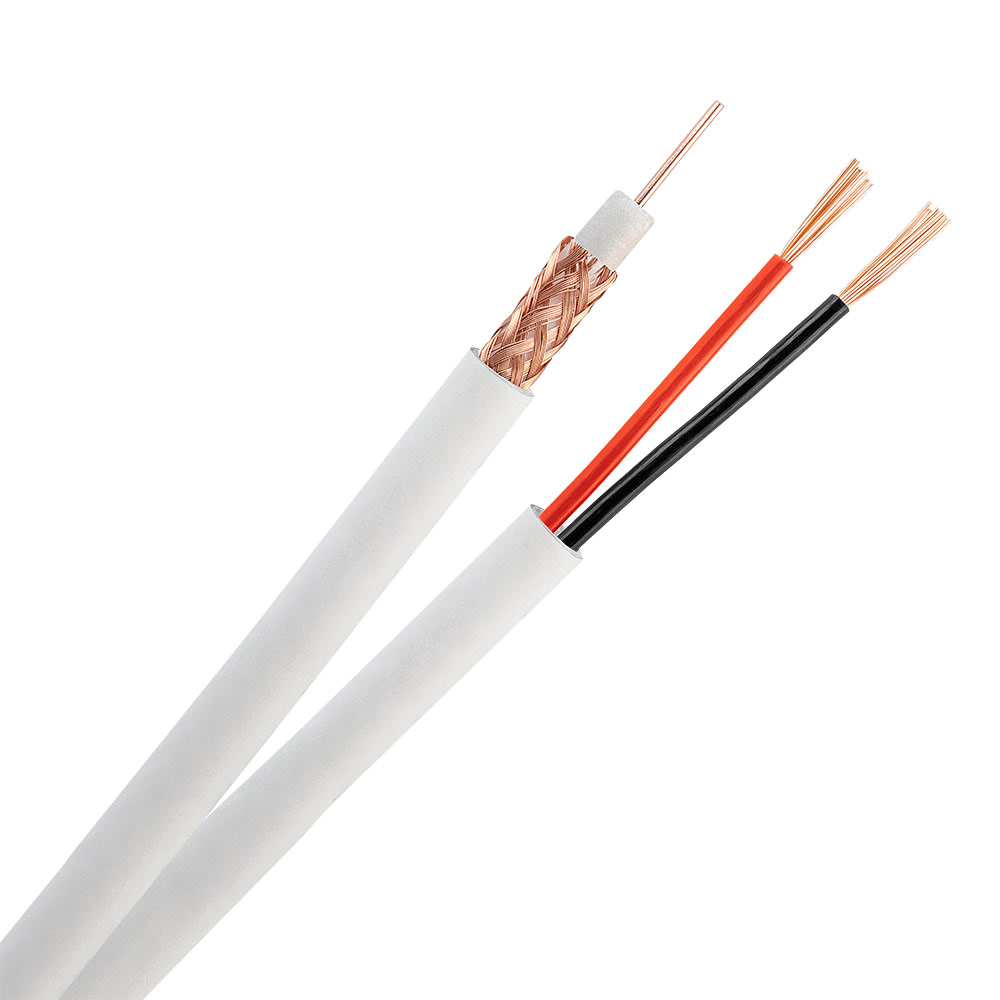

As discussed in industry literature, RG11 CCAM wire is extensively used in telecommunications for signal transmission over long distances due to its lightweight and high conductivity. It is exceptional for automotive wiring where reduced weight can improve fuel efficiency. Moreover, its application extends to data transmission cables, making it a cost-effective option for both household and industrial electrical wiring needs.

Product After-Sales Service

- Comprehensive technical support and troubleshooting

- Warranty coverage for manufacturing defects

- Replacement and repair services

- Dedicated customer care team for quick resolutions

Product Transportation

Our RG11 CCAM wire is packaged securely for minimal transit damage and is available for shipping from Ningbo port. We ensure timely delivery with reliable carriers and offer tracking services for shipment updates.

Product Advantages

- Cost-effective solution due to the use of copper-clad aluminum

- Excellent conductivity with a protective copper layer

- Lightweight, making it ideal for applications where weight is a concern

- Enhanced tensile strength due to magnesium addition

Product FAQ

1. What makes CCAM wire a good alternative to pure copper?

As a supplier, CCAM wire offers a cost-effective solution without compromising on conductivity. The copper cladding ensures excellent electrical transmission while the aluminum core reduces weight, making it a viable alternative to pure copper.

2. How does the copper layer protect against corrosion?

The copper cladding acts as a barrier to environmental factors, preventing oxidation and corrosion of the aluminum core. This protection enhances the lifespan and reliability of the wire in various conditions.

3. Is CCAM wire suitable for high-stress applications?

CCAM wire is suitable for moderate stress applications. However, for extreme conditions, pure copper might be preferable due to its robustness. The supplier can discuss specific needs for custom solutions.

4. Can this wire be used for automotive applications?

Yes, CCAM wire is ideal for automotive applications due to its lightweight nature, which contributes to vehicle weight reduction and fuel efficiency improvements.

5. What is the typical lifespan of CCAM wire in outdoor applications?

Given its corrosion-resistant properties, CCAM wire can last several years outdoors with minimal degradation, making it a reliable choice for outdoor installations.

6. What are the limitations of using CCAM wire?

While CCAM wire is cost-effective and lightweight, it may not be suitable for extremely high-temperature conditions due to the aluminum core, which could affect its long-term reliability.

7. How does the magnesium component enhance the wire?

The magnesium in CCAM wire improves tensile strength and mechanical durability, making it more resistant to physical strain than pure aluminum wire.

8. What are the packaging options available?

We offer flexible packaging solutions to meet specific requirements, ensuring safe transit and storage. Options can be discussed with the supplier for tailored solutions.

9. Does CCAM wire support high-frequency data transmission?

Yes, CCAM wire is designed to handle high-frequency transmissions efficiently, making it suitable for modern telecommunications and data transfer applications.

10. Can I request custom lengths for CCAM wire orders?

Custom lengths are available to accommodate specific project requirements. Please consult with the supplier for feasible options and order guidelines.

Product Hot Topics

1. The Future of CCAM Wire in Telecommunications

Industry experts predict that as demand for cost-efficient solutions increases, CCAM wire will see greater adoption in telecommunications. Its lightweight and high conductivity make it a preferred choice for long-distance signal transmission, bringing advanced technology to the fore. Suppliers are increasingly focusing on research to enhance its characteristics further.

2. Comparative Analysis: CCAM Wire vs. Copper Wire

In recent analyses, CCAM wire emerges as a cost-saving alternative to traditional copper wiring. By combining the conductive properties of copper with the lightweight benefits of aluminum, suppliers provide a balanced solution for multiple applications. Companies considering a shift should weigh the specific advantages of each depending on their operational needs.

3. The Role of CCAM Wire in Reducing Vehicle Weight

Automotive manufacturers are prioritizing weight reduction to enhance fuel efficiency, and CCAM wire has become integral in this transition. Suppliers offer innovative wiring solutions that maintain performance standards while contributing to overall vehicle weight reduction, marking a significant advancement in automotive design.

4. Environmental Impact of Using CCAM Wire

As sustainability takes center stage, the use of CCAM wire offers a greener alternative by reducing reliance on copper, a finite resource. Suppliers promoting CCAM wire contribute to lower environmental impact through material optimization, aligning with global sustainability goals.

5. Advances in CCAM Wire Manufacturing Techniques

With technological advancements, suppliers are enhancing CCAM wire manufacturing processes to improve bond integrity between its metal components. This innovation leads to better performance metrics, making CCAM wire increasingly reliable for various high-demand applications.

6. Challenges in Deploying CCAM Wire in Harsh Environments

While CCAM wire is cost-effective, deploying it in harsh environments poses challenges due to potential core material limitations. Suppliers work on overcoming these issues by developing custom solutions and coatings to extend wire life and performance in tougher conditions.

7. CCAM Wire Transforming Data Transmission Solutions

In the data-driven world, CCAM wire is redefining expectations for high-frequency data transmission. Its robust yet lightweight nature appeals to industries looking for efficient ways to upgrade their infrastructure without excessive cost. Suppliers continue to expand its applications, paving the way for future growth.

8. Customer Experiences with CCAM Wire Suppliers

Feedback from users highlights the reliability and cost savings achieved with CCAM wire. Many customers appreciate the tailored support and solutions offered by suppliers, which help streamline operations and enhance overall satisfaction with the product.

9. The Economic Advantages of CCAM Wire for Industries

By reducing raw material costs while maintaining essential performance qualities, CCAM wire offers substantial economic benefits. Suppliers focus on providing detailed cost analyses to illustrate potential savings for businesses considering this alternative.

10. Ensuring Quality in Mass Production of CCAM Wire

As demand for CCAM wire grows, maintaining quality standards in mass production becomes crucial. Leading suppliers employ rigorous testing protocols and quality management systems to ensure each batch meets expected performance criteria, providing peace of mind for buyers.

Image Description