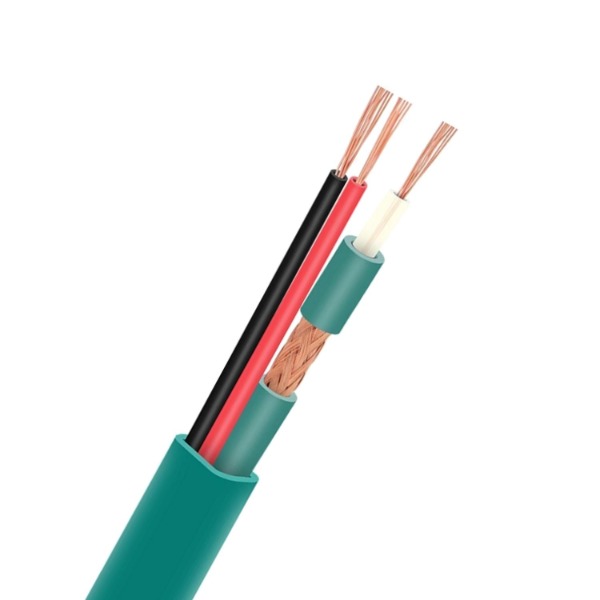

Product Main Parameters

| Parameter | Details |

|---|---|

| Center Conductor | 7*0.2 Copper |

| Dielectric | 3.7SPE |

| Jackets | Green coating PVC for indoor |

| Color | Customized |

| Weight | 6.5KG/100m |

Common Product Specifications

| Specification | Details |

|---|---|

| Type | KX7 with Power Cable |

| Usage | VIDEO/CCTV |

| Connector | BNCDC |

| Origin | Hangzhou Zhejiang |

Product Manufacturing Process

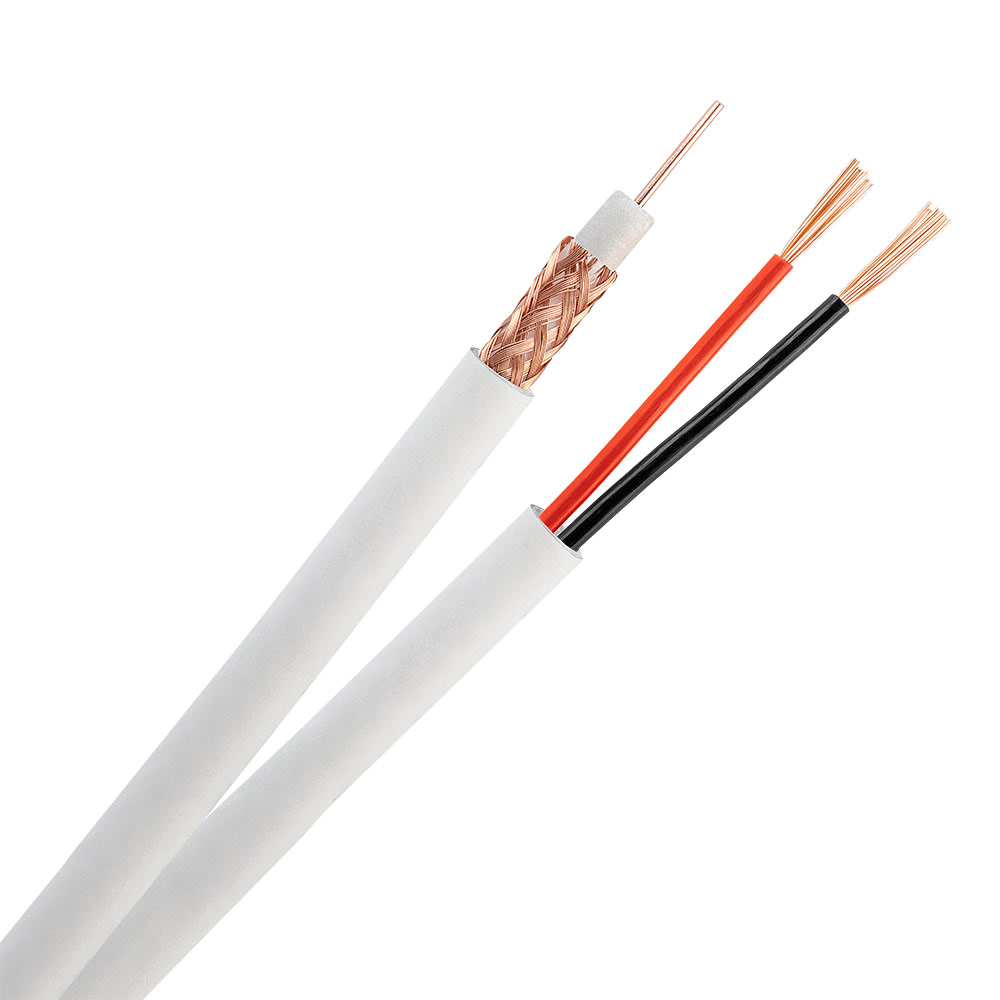

The manufacturing process of RG59 cable involves several key steps that ensure the highest standards of quality for reliable performance in video transmission applications. It starts with the preparation of the center conductor, typically made of solid copper or copper-clad steel, providing durability and efficient signal conduction. The conductor is insulated with a dielectric material, often polyethylene, to maintain optimal distance from the shielding layer. The cable is then shielded with one or more layers, usually comprising braided copper or aluminum, that effectively minimize electromagnetic interference and radio frequency interference. The final step involves applying an outer jacket, made of PVC or flame-retardant polyurethane, which provides physical protection and enhances cable flexibility. Throughout the manufacturing process, rigorous quality control measures are applied to ensure the cable meets industry standards and customer expectations.

Product Application Scenarios

RG59 cables are predominantly used in various low-frequency applications, particularly in video and CCTV systems. Their characteristics make them ideal for scenarios where high-frequency signals are not a primary concern and where cable runs are relatively short. Common applications include closed-circuit television (CCTV) systems, where they efficiently transmit analog video signals necessary for surveillance purposes. Additionally, RG59 cables are employed in low-power video transmission for standard-definition television and some digital video interfaces. While they can be used in cable television and satellite installations, other cables like RG6 are generally preferred for longer runs due to lower attenuation rates over long distances. It is important to consider these scenarios when selecting an RG59 cable to ensure optimal performance and reliability.

Product After-Sales Service

We provide comprehensive after-sales support to ensure user satisfaction with our RG59 cable products. This includes technical assistance for installation, troubleshooting support, and guidance on optimal usage. Our customer service team is available to address any queries or concerns, ensuring that our clients can rely on the quality and durability of our cables. We are committed to maintaining long-term partnerships with our customers by offering prompt and effective post-purchase assistance.

Product Transportation

Our RG59 cables are packed using standard export packaging to ensure safe and secure transport. Depending on the order size and preferences, packaging can include coil reels, plastic drums, wooden drums, color boxes, or carton boxes. We work with reliable logistics partners to facilitate timely delivery and offer shipping options through Ningbo Port to various global destinations, ensuring that our products reach customers efficiently and in perfect condition.

Product Advantages

- Cost-effective solution for video surveillance systems

- Reliable transmission for short cable runs

- Customizable color and packaging options

- High-quality construction with solid copper conductor

- Complies with industry standards such as SGS, CE, RoHS, and ISO9001

Product FAQ

What is the primary use of RG59 cable from this manufacturer?

Our RG59 cable is primarily used for video signal transmission in CCTV systems, providing reliable and cost-effective solutions for surveillance applications in regions like Algeria and Morocco.

How does the manufacturer ensure the quality of RG59 cable?

We employ rigorous quality control measures at every stage of the manufacturing process to ensure our RG59 cables meet industry standards and deliver consistent performance.

What are the typical applications of RG59 cable?

RG59 cables are commonly used in CCTV systems, low-power video transmission, and some older cable television setups, especially where cable runs are short, and high-frequency signals are not critical.

Can the manufacturer customize the cable specifications?

Yes, our manufacturing capabilities allow us to provide customized options for cable colors and packaging, ensuring they meet specific customer requirements.

What distinguishes this manufacturer's RG59 cable from others?

Our RG59 cables are distinguished by their high-quality materials, advanced manufacturing processes, and compliance with international standards, ensuring reliable performance and longevity.

What are the transport and packaging options for large orders?

We offer various packaging options, including coil reels and drums, to accommodate large orders, and employ reliable shipping partners to ensure efficient and safe delivery globally.

Is after-sales support available from this manufacturer?

Yes, we provide dedicated after-sales support to assist customers with installation, troubleshooting, and any other post-purchase concerns.

What is the minimum order quantity for RG59 cable?

The minimum order quantity for our RG59 cable is 30 kilometers, allowing us to offer competitive pricing and efficient production timelines.

What are the features of the cable jackets?

Our RG59 cables feature robust PVC jackets with customizable colors, offering durability and protection suitable for indoor installations.

How does the impedance of RG59 cable benefit video applications?

The 75-ohm impedance of RG59 cable makes it particularly suitable for transmitting video signals, ensuring minimal signal loss and high-quality video output in CCTV systems.

Product Hot Topics

- Comment on RG59 Cable Usage in CCTV Systems:

The choice of RG59 cable for CCTV applications remains popular due to its proven reliability in video transmission. Many installers in Algeria and Morocco favor it for its cost-effectiveness and compatibility with analog surveillance systems. However, as digital solutions become more prevalent, the discussion is shifting towards exploring newer alternatives like RG6 for enhanced performance. Nevertheless, the RG59 cable manufactured by Aston Cable maintains a strong reputation for quality and consistency, ensuring that it continues to be a go-to option for current surveillance needs.

- Discussion on Cable Manufacturing Standards:

The manufacturing standards adhered to by Aston Cable are a testament to their commitment to quality. By aligning with internationally recognized certifications such as ISO9001 and RoHS, the manufacturer ensures that its RG59 cable stands out in a competitive market. Such standards not only guarantee product reliability but also reinforce the company's reputation as a leading manufacturer in the cable industry. As the demand for high-quality cables grows in regions like South Africa, particularly Algeria and Morocco, maintaining these standards becomes even more crucial.

- RG59 vs. RG6: A Continuing Debate:

The ongoing debate between choosing RG59 and RG6 cables often centers around performance and application needs. While RG6 offers lower attenuation and is better suited for longer runs and higher frequency applications, RG59 holds its ground in specific scenarios like short-run CCTV installations. For many manufacturers, including Aston Cable, providing both options allows them to cater to diverse market needs. As technology advances, this conversation is likely to evolve, focusing on balancing cost, performance, and user requirements.

- Importance of Quality Control in Cable Manufacturing:

Quality control is paramount in cable manufacturing to ensure product efficacy and customer satisfaction. Aston Cable's rigorous quality control processes exemplify this, where each RG59 cable undergoes meticulous inspection and testing before reaching the market. Such diligence not only enhances the manufacturer's credibility but also reassures customers of the durability and reliability of their products. In an industry driven by precision and performance, maintaining high-quality standards is non-negotiable.

- The Impact of Cable Material Choices on Performance:

The choice of materials in cable manufacturing, particularly the conductor and shielding, significantly impacts performance. For RG59 cables, using solid copper or copper-clad steel for the conductor can determine conductivity and cost efficiency. Aston Cable's use of high-quality copper ensures optimal signal transmission, reflecting a crucial aspect of manufacturer responsibility. As manufacturers strive to balance quality and cost-effectiveness, material choice remains a hot topic within the industry.

- Advancements in Surveillance Technology and Cable Needs:

As surveillance technology evolves, the demand for cables that support high-definition and digital data transmission increases. While RG59 continues to serve traditional analog systems, the shift towards digital solutions necessitates adaptation. Manufacturers like Aston Cable monitor these trends closely, adapting their product lines to incorporate cables that meet emerging technological requirements. This dynamic adaptation underscores the need for flexibility and innovation within the industry.

- Comparing Indoor vs. Outdoor Cable Requirements:

The decision between using indoor and outdoor-rated cables depends significantly on environmental factors. RG59 cables with PVC jackets are suitable for indoor use due to their flexibility and protective qualities. However, outdoor installations might require different materials for weather resistance. For manufacturers, offering both options ensures they can meet the varied needs of their clientele. Understanding these differences is crucial for both manufacturers and end-users to ensure optimal cable performance and longevity.

- Customer Satisfaction in Cable Product Offerings:

Customer satisfaction remains a key focus for manufacturers like Aston Cable. By offering products that align with customer needs and expectations, such as customized options and comprehensive support, manufacturers can strengthen their market position. Feedback from regions such as Algeria and Morocco highlights the importance of responsiveness and quality assurance in maintaining customer trust. As the market becomes increasingly competitive, focusing on customer satisfaction will likely remain a strategic priority.

- Exploring Future Trends in Cable Technology:

The future of cable technology points towards greater integration with digital systems and higher bandwidth capabilities. While RG59 continues to serve specific niches, the development of alternatives like fiber optics suggests a transformative shift in industry standards. Manufacturers must anticipate these trends, investing in research and development to remain competitive. For Aston Cable, staying abreast of technological advancements ensures they can continue to meet and exceed customer needs in a rapidly changing landscape.

- Navigating Global Supply Chain Challenges:

Global supply chain challenges, particularly in recent years, have emphasized the importance of strategic planning and flexibility for cable manufacturers. Aston Cable's ability to navigate these challenges while maintaining production efficiency and quality is indicative of their robust operational strategy. By collaborating with reliable logistics partners and focusing on strategic sourcing, manufacturers can mitigate supply chain disruptions. This proactive approach is crucial for sustaining product availability and meeting international market demands.

Image Description