Product Main Parameters

| Parameter | Cat5e | Cat6 |

|---|---|---|

| Bandwidth | 100 MHz | 250 MHz |

| Conductor | 24AWG Bare Copper | 24AWG Bare Copper |

| Insulation | HDPE | HDPE |

| Shielding | None | None |

| Jackets | PVC, LSZH, PE | PVC, LSZH, PE |

| Compliance | RoHS, CE, IEC | RoHS, CE, IEC |

Common Product Specifications

| Specification | Details |

|---|---|

| Place of Origin | China |

| Brand Name | ASTON or OEM |

| Certification | SGS CE ROHS ISO9001 |

| MOQ | 50km |

| Packaging | Normal export packaging |

| Daily Output | 200KM |

| Delivery Port | Ningbo |

Product Manufacturing Process

The manufacturing process for Cat5e and Cat6 cables involves multiple stages to ensure quality and performance. The first stage includes drawing and annealing the copper wires to achieve the desired gauge. This is followed by the insulation process, where high-density polyethylene (HDPE) is extruded onto the copper wire. The wires are then twisted into pairs to minimize crosstalk and electromagnetic interference. The next step involves the application of the outer jacket, which can be made from PVC, LSZH, or PE. Finally, the cables undergo rigorous testing and quality control to comply with industry standards such as RoHS, CE, and IEC. This comprehensive process ensures that the cables provide reliable data transmission and durability for various networking applications.

Product Application Scenarios

Cat5e and Cat6 cables are versatile and widely used in various application scenarios. In office settings, these cables are crucial for establishing reliable Ethernet networks, connecting computers, servers, and other networking devices. They are also used in data centers where high-speed data transfer is essential. In residential environments, Cat5e and Cat6 cables are used for home networking, enabling internet connectivity, streaming, and smart home applications. Additionally, these cables are deployed in CCTV systems to provide high-definition video transmission, ensuring security and surveillance. The robustness and flexibility of Cat5e and Cat6 cables make them suitable for both indoor and outdoor installations, adapting to different environmental conditions.

Product After-Sales Service

Aston Cable offers comprehensive after-sales service to ensure customer satisfaction. Our services include technical support for installation and troubleshooting, warranty coverage for manufacturing defects, and replacement services for damaged or faulty products. We also provide detailed product documentation and user manuals to assist with setup and maintenance.

Product Transportation

Our products are packed in standard export packaging to ensure they are protected during transit. We use reputable shipping companies and offer various shipping options, including air, sea, and land transport, to meet the diverse needs of our customers. Delivery times and costs vary depending on the destination and selected shipping method.

Product Advantages

- High-quality copper conductors for improved performance and longevity

- Enhanced bandwidth and data transfer speeds

- Reduced crosstalk and electromagnetic interference

- Backward compatibility with earlier standards

- Compliant with RoHS, CE, and IEC standards

Product FAQ

- What is the difference between Cat5e and Cat6? Cat6 cables offer higher bandwidth (250 MHz vs. 100 MHz for Cat5e) and better performance, making them suitable for more demanding applications.

- Can I use Cat6 cables in a Cat5e network? Yes, Cat6 cables are backward compatible with Cat5e and can be used in existing Cat5e networks.

- What is the maximum length for Cat5e and Cat6 cables? Both Cat5e and Cat6 cables can support lengths up to 100 meters for Gigabit Ethernet, but Cat6 supports higher speeds at shorter distances.

- Are your cables RoHS compliant? Yes, our Cat5e and Cat6 cables are RoHS compliant and meet international safety standards.

- What types of jackets are available for your cables? We offer PVC, LSZH, and PE jackets for our Cat5e and Cat6 cables.

- Do you offer OEM services? Yes, we provide OEM services and can customize the cables with your brand logo and specifications.

- What is the minimum order quantity (MOQ)? The MOQ for our Cat5e and Cat6 cables is 50 kilometers.

- How do you ensure cable quality? We have advanced manufacturing equipment, rigorous testing processes, and adhere to strict quality control standards to ensure product quality.

- What is the daily production capacity? Our factory can produce up to 500 kilometers of finished cables per day.

- What payment methods do you accept? We accept various payment methods, including bank transfers, letters of credit, and other negotiable terms.

Product Hot Topics

- Importance of Choosing the Right Cable Supplier Choosing a reliable cable supplier is crucial for ensuring the performance and longevity of your network. A reputable supplier like Aston Cable provides high-quality Cat5e and Cat6 cables that meet industry standards, ensuring optimal data transmission and network reliability.

- Future-Proofing Your Network with Cat6 Cables As network demands increase, investing in Cat6 cables can be a proactive step to future-proof your infrastructure. Cat6 cables offer higher bandwidth and better performance, making them suitable for high-speed applications and reducing the need for frequent upgrades.

- Comparing Cat5e and Cat6 in Real-World Scenarios While both Cat5e and Cat6 cables are suitable for various networking applications, Cat6 cables offer distinct advantages in terms of speed, bandwidth, and interference resistance. Understanding these differences can help you make an informed choice based on your specific network requirements.

- How to Optimize Your Network with Quality Cables High-quality cables are essential for optimizing network performance. Using Cat5e and Cat6 cables from a trusted supplier like Aston Cable ensures reliable data transmission, minimized interference, and overall network efficiency.

- The Role of Ethernet Cables in Modern Networking Ethernet cables like Cat5e and Cat6 play a critical role in modern networking by providing reliable wired connections. These cables enable high-speed data transfer, support various applications, and contribute to the overall stability and performance of the network.

- Benefits of Using Copper Conductors in Network Cables Copper conductors in network cables, such as those used in Cat5e and Cat6, offer superior conductivity, durability, and resistance to corrosion. These benefits translate to better performance and longer cable lifespan, making copper cables a preferred choice for many applications.

- Understanding Cable Jacket Materials and Their Importance The choice of cable jacket material, such as PVC, LSZH, or PE, can impact the cable's performance, durability, and safety. Each material has its advantages, and selecting the right one depends on the specific requirements of the installation environment.

- The Impact of Crosstalk on Network Performance Crosstalk, or signal interference between adjacent wires, can significantly impact network performance. Cat6 cables are designed with tighter twists and physical separators to reduce crosstalk, ensuring more reliable data transmission compared to Cat5e.

- Cost-Effective Networking Solutions with Cat5e Cables For networks that do not require the highest speeds, Cat5e cables provide a cost-effective solution without compromising performance. They offer sufficient bandwidth and data rates for most everyday applications, making them a practical choice for many users.

- Ensuring Network Security with Quality Cables High-quality network cables are essential for maintaining network security. Poor-quality cables can lead to data loss or corruption, compromising the integrity of your network. Investing in reliable Cat5e and Cat6 cables from a trusted supplier helps protect your data and network infrastructure.

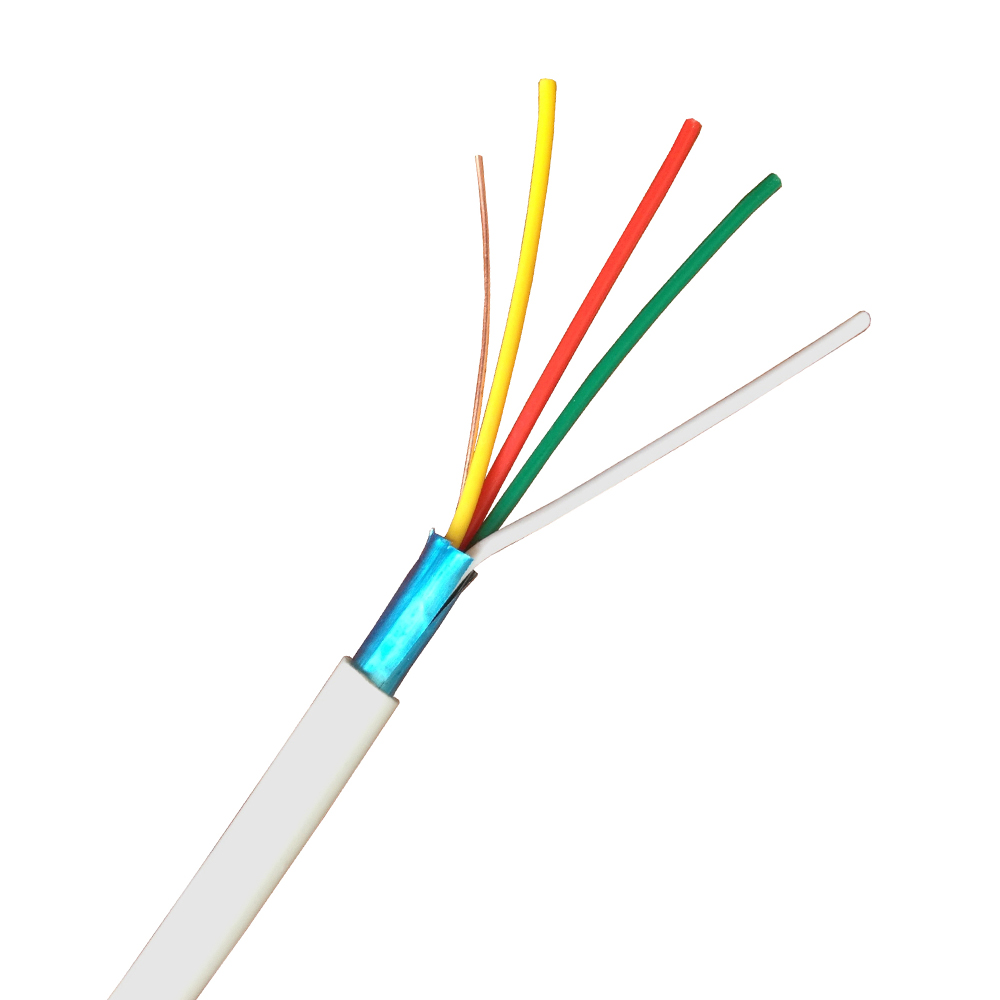

Image Description