Product Main Parameters

| Parameter | Value |

|---|---|

| Conductor Material | Copper Clad Aluminum |

| Conductor Diameter | 1.63mm (14AWG) |

| Impedance | 75 ohm |

| Jacket Color | Black |

| Jacket Material | PVC, PE |

Common Product Specifications

| Specification | Value |

|---|---|

| Length | 304.8 m (1000 ft) |

| Dielectric Strength | 4000 Vdc |

| Capacitance | 52.493 pF/m |

| Velocity of Propagation | 84% |

Product Manufacturing Process

The manufacturing process of Copper Clad Aluminum (CCA) conductors involves the metallurgical bonding of a thin copper layer over an aluminum core. This is achieved through a cladding process, applying high pressure and thermal treatment to ensure a robust bond at the atomic level, preventing separation during use. The combination of copper’s electrical conductivity and aluminum’s lightweight nature offers an optimal balance for many applications, as highlighted in numerous industry journals.

Product Application Scenarios

CCA conductors are commonly used in several fields owing to their cost-effectiveness and performance. In telecommunications, they are frequently utilized for coaxial and network cables, offering a lightweight solution without compromising on electrical efficiency. In the automotive and aerospace sectors, their reduced weight contributes to fuel efficiency, as discussed in various studies on material science and engineering.

Product After-Sales Service

Our commitment to customer satisfaction continues post-purchase with comprehensive after-sales support. This includes installation guidance, troubleshooting, and easy access to technical support team for any inquiries related to our products.

Product Transportation

The product is securely packaged for international transportation, ensuring it reaches its destination without any damage. We collaborate with reliable logistic providers to expedite delivery while ensuring compliance with all safety standards.

Product Advantages

- Cost-efficient due to reduced copper use.

- Lightweight construction.

- High electrical conductivity remains intact.

- Corrosion-resistant properties enhance longevity.

Product FAQ

- What are Copper Clad Aluminum conductors?

CCA conductors consist of an aluminum core clad with copper, combining the electrical advantages of copper with the lightweight properties of aluminum, often used by suppliers for reducing costs.

- Why choose CCA over pure copper?

CCA offers significant cost savings and weight reduction, which are beneficial to suppliers in industries where these factors matter, such as telecommunications and automotive.

- What applications are suitable for CCA cables?

CCA cables are ideal for telecommunications, residential wiring, and sectors like automotive and aerospace, where weight and cost savings are prioritized by suppliers.

- How does the cladding process work?

Through metallurgical bonding under heat and pressure, copper is fused over an aluminum core to create CCA conductors, maintaining both metals' integrity and ensuring reliability as stressed by suppliers.

- What is the lifespan of a CCA conductor?

The copper layer protects the aluminum core against corrosion, giving CCA conductors a long lifespan, often meeting the rigorous standards set by top suppliers.

- Is CCA suitable for long-distance data transmission?

Yes, the electrical performance of CCA conductors supports long-range signal transmission effectively, making it a popular choice among suppliers for network and communication applications.

- How do CCA conductors fare in extreme conditions?

CCA conductors perform well across various environments due to the corrosion-resistant copper layer, providing durability under challenging conditions, as highlighted by suppliers.

- Can CCA be used outdoors?

Yes, CCA conductors are designed to withstand outdoor conditions, providing reliable performance and protection against environmental factors, which is why suppliers often recommend them for such scenarios.

- What are the safety standards for CCA conductors?

CCA conductors adhere to international safety standards, including RoHS and CE compliance, ensuring their appropriateness for various applications, as guaranteed by suppliers.

- How does CCA impact installation and handling?

The lighter weight of CCA conductors eases installation and handling, making them a convenient and efficient choice for suppliers in large-scale projects.

Product Hot Topics

- Environmental Impact of CCA Conductors

As suppliers seek sustainable options, CCA conductors emerge as a viable choice due to their reduced copper usage, contributing to resource conservation without compromising on performance.

- Cost-Effectiveness of CCA Conductors

Suppliers appreciate the economic advantage of CCA conductors as they provide a cheaper alternative to pure copper without sacrificing essential electrical characteristics, making them suitable for budget-conscious projects.

- Technological Advances in CCA Production

Recent technological advancements in the production process have enhanced the quality and performance of CCA conductors, making them a primary choice for suppliers aiming for high-grade applications.

- CCA Conductors in Telecommunications

Suppliers in the telecommunications sector are increasingly adopting CCA conductors due to their lightweight and cost-saving properties, which do not compromise connectivity quality.

- CCA Conductors in Automotive Industry

As vehicle technology advances, suppliers in the automotive industry turn to CCA conductors to enhance fuel efficiency through weight reduction, without losing electrical performance.

- Future of CCA Conductors

With ongoing research and development, suppliers are optimistic about the future of CCA conductors, expecting further improvements in performance and application versatility.

- Safety and Standards Compliance

Compliance with international safety standards is crucial for suppliers of CCA conductors, ensuring their products are safe for a wide range of applications worldwide.

- Challenges of Using CCA Conductors

While offering many benefits, suppliers acknowledge challenges related to thermal expansion and mechanical strength, emphasizing the importance of appropriate design and application.

- Consumer Perception of CCA Conductors

Educating consumers about the benefits and limitations of CCA conductors is a focus for suppliers, ensuring informed decisions when selecting materials for various projects.

- Impact on Global Supply Chain

As demand for cost-effective alternatives grows, suppliers are adapting to integrate CCA conductors into the global supply chain, supporting diverse industries worldwide.

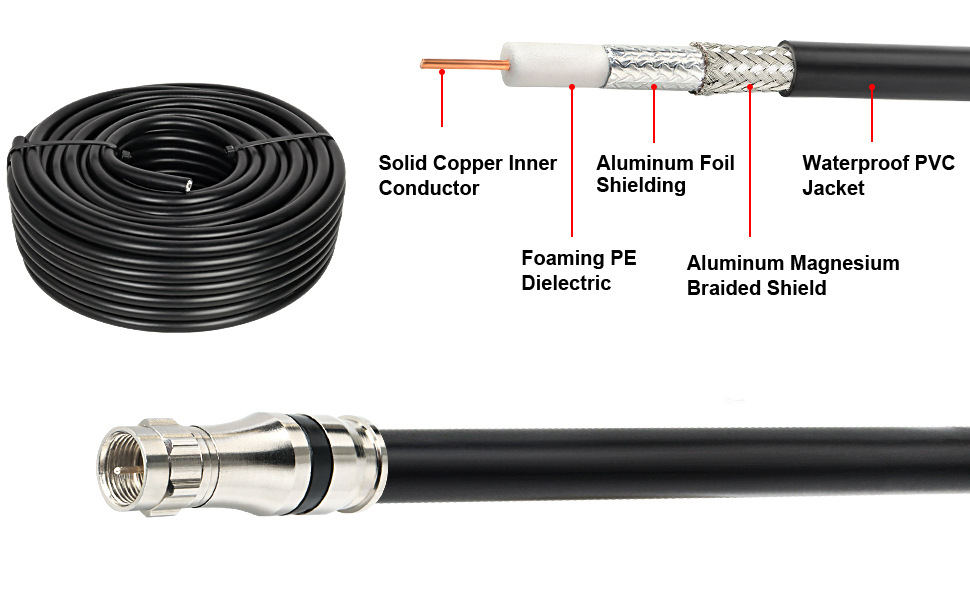

Image Description