Product Main Parameters

| Parameter | Detail |

|---|---|

| Center Conductor Diameter | 0.0641 in |

| Diameter Over Dielectric | 7.112 mm |

| Jacket Thickness | 0.508 mm |

| Characteristic Impedance | 75 ohm |

Common Product Specifications

| Specification | Detail |

|---|---|

| Color | Black |

| Usage | Data transmission |

| Conductor Material | Copper |

| Jacket Material | PVC, PE |

Product Manufacturing Process

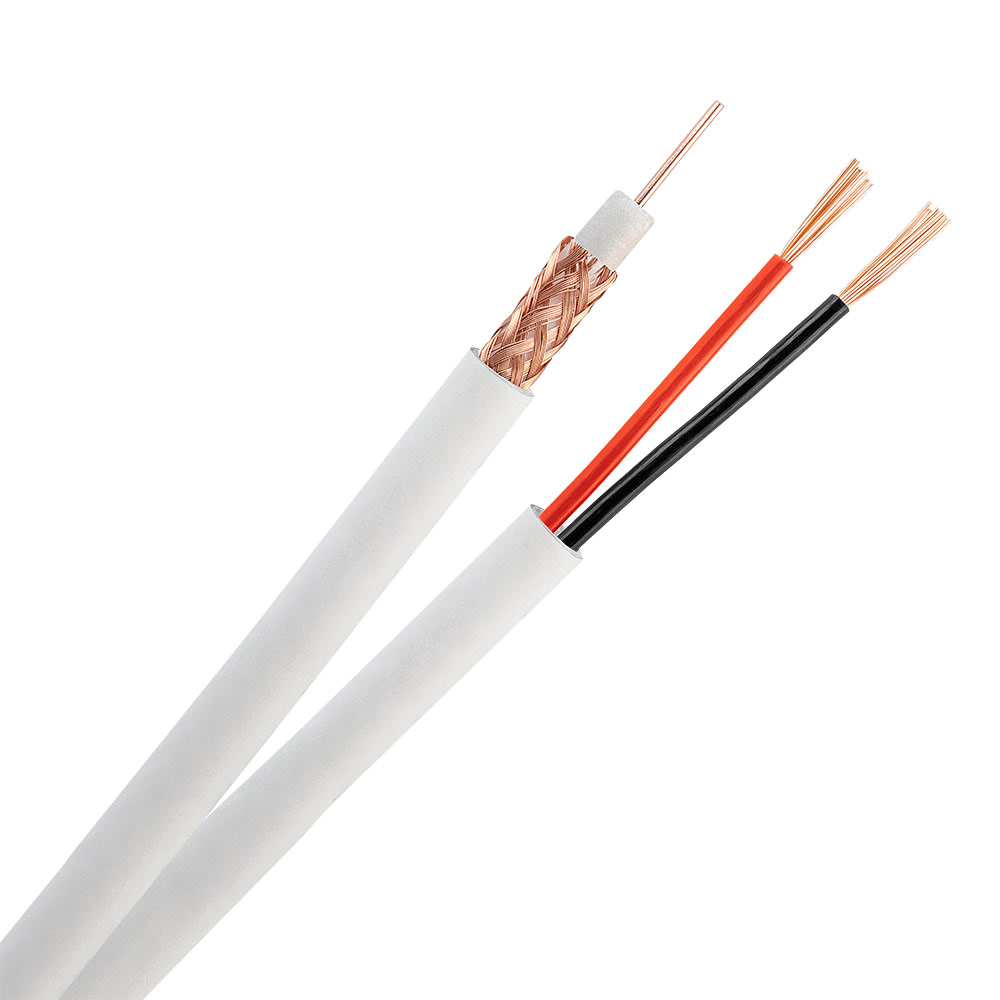

According to authoritative resources, the manufacturing process of 4 core coaxial cables involves several precise steps to ensure quality and efficiency. Initially, the inner conductors are drawn and coated with a dielectric insulator. A shielding layer is meticulously applied to avoid electromagnetic interference. Finally, a protective outer sheath is added. This structured process guarantees durability and optimal signal integrity, which are vital for high-performance data transmission tasks across varied environments.

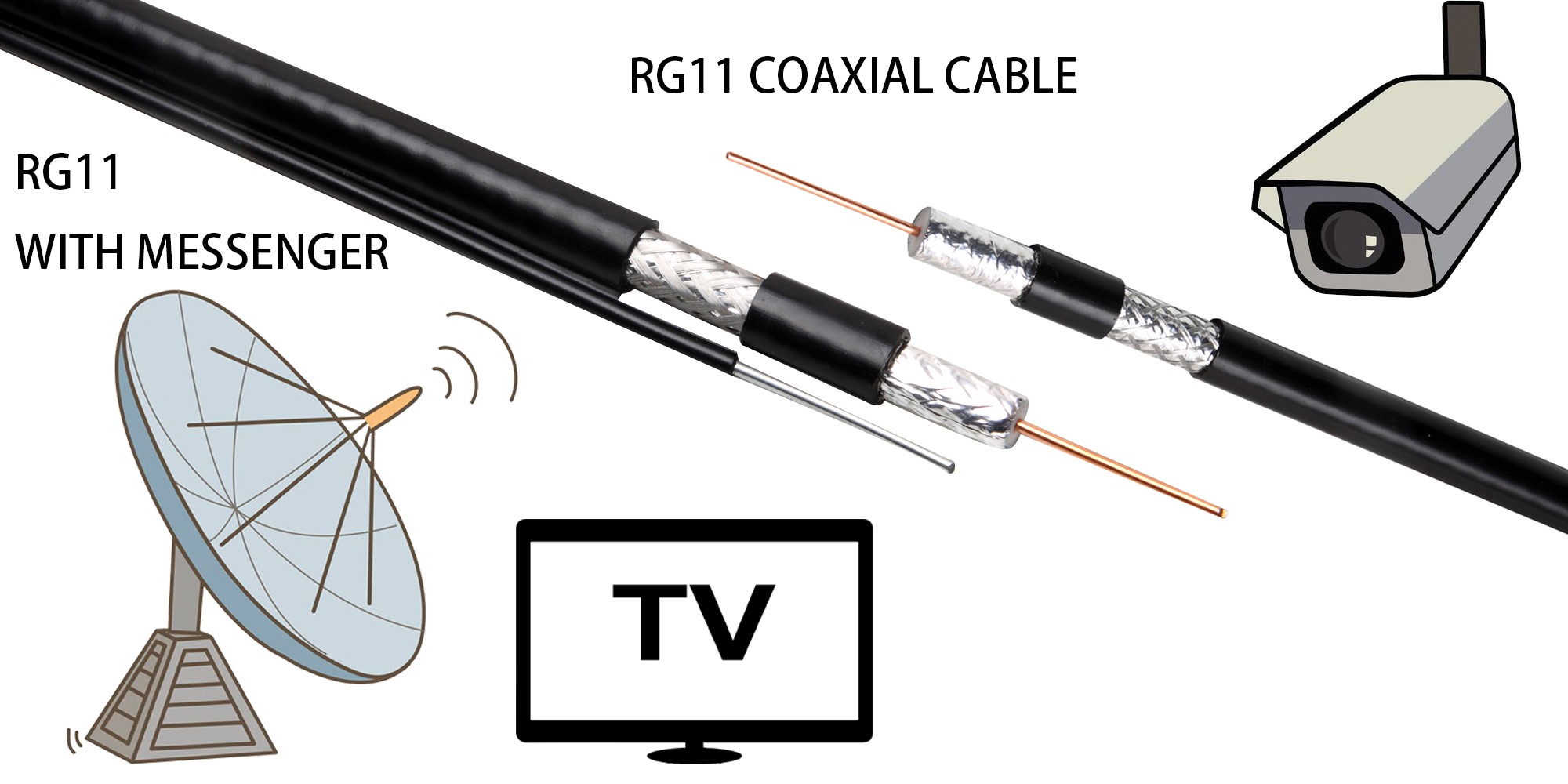

Product Application Scenarios

In reviewing industry studies, 4 core coaxial cables are crucial in applications demanding robust transmission capabilities and minimized interference. They are commonly utilized in telecommunications, handling multiple communication channels; CCTV setups, efficiently transmitting numerous camera feeds; and broadcasting, carrying various channel signals seamlessly. Additionally, 4 core coaxial cables have niche applications in network setups requiring fortified shielding, demonstrating their versatility and reliability in dynamic environments.

Product After-Sales Service

We offer comprehensive after-sales support for our 4 core coaxial cables, including a 24/7 customer care line, product warranty services, and technical assistance for installation and troubleshooting.

Product Transportation

Carefully packaged for international transit, our 4 core coaxial cables are shipped from Ningbo port, ensuring they arrive in optimal condition, ready for immediate deployment.

Product Advantages

- Superior Signal Integrity: 4 core coaxial cables are designed to provide excellent protection against electromagnetic interference.

- Multi-Signal Handling: Simultaneously supports various transmissions, suitable for complex systems.

- Durability: Built for longevity with redundant cores for increased reliability.

Product FAQ

- What is the main use of a 4 core coaxial cable? 4 core coaxial cables are primarily used for transmitting multiple signals with enhanced protection against interference, suitable for CCTV, telecom, and broadcasting.

- How long can a 4 core coaxial cable transmit a signal? The cable can transmit signals effectively over relatively long distances; however, to avoid degradation, using amplifiers or repeaters is recommended for extended runs.

Product Hot Topics

- 4 Core Coaxial Cable: Essential for Modern Surveillance Systems In today's security landscape, 4 core coaxial cables are indispensable for surveillance, enabling reliable transmission of multiple camera feeds to centralized locations.

- Debate: Coaxial Cables vs. Fiber Optics While fiber optics offer higher bandwidth, 4 core coaxial cables are preferred in scenarios demanding robustness and ease of installation, particularly where interference is a concern.

Image Description