Product Details

| Parameter | Specification |

|---|---|

| Place of Origin | China |

| Brand Name | ASTON or OEM |

| Certification | SGS CE ROHS ISO9001 |

| Coaxial Cable Daily Output | 200KM |

| Minimum Order Quantity | 50km |

| Price (USD) | Negotiate |

| Packaging Details | Normal export packaging |

| Supply Ability | 25000KM/Per year |

| Delivery Port | Ningbo |

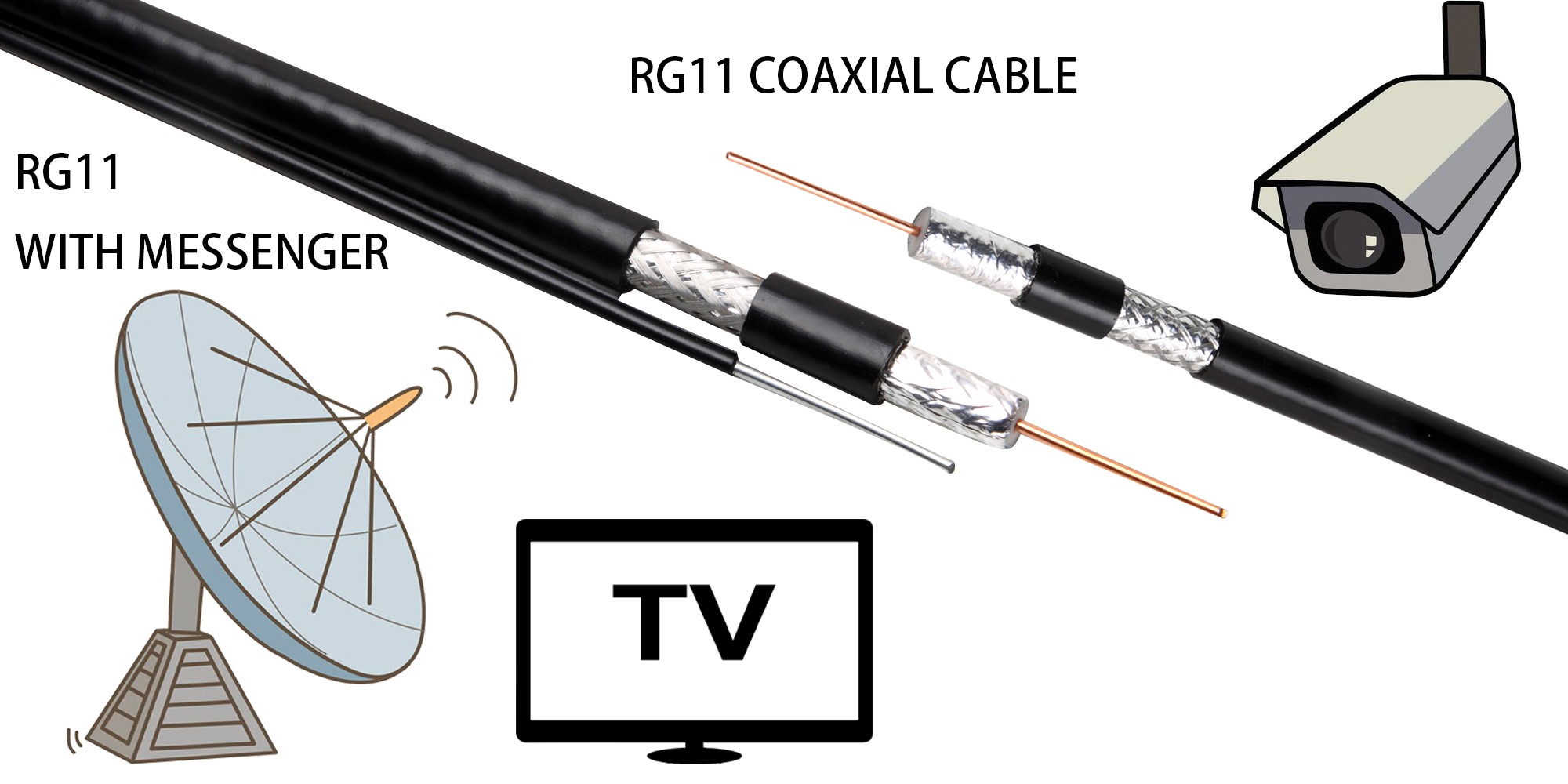

| Product Name | RG11 Coaxial cable |

| Jackets | PVC,PE |

| Color | Black |

| Conductor | 1.63mm 14AWG |

| Usage | Radio guide cable |

| Logo | OEM |

| Industrial Use | Data transmission cable |

| Origin | Hangzhou Zhejiang |

| Cable Length | 304.8 m | 1000 ft |

| Diameter Over Center Conductor | 0.0641 in per 1 strand |

| Diameter Over Dielectric | 7.112 mm | 0.28 in |

| Diameter Over Jacket Tolerance | ±0.008 in |

| Diameter Over Jacket | 9.169 mm | 0.361 in |

| Diameter Over Shield (Braid) | 8.179 mm | 0.322 in |

| Jacket Thickness | 0.508 mm | 0.02 in |

| Jacket Thickness, Minimum Spot | 0.406 mm | 0.016 in |

| Center Conductor Gauge | 14 AWG |

| Inner Shield (Braid) Gauge | 34 AWG |

| Capacitance | 52.493 pF/m | 16 pF/ft |

| Characteristic Impedance | 75 ohm |

| Characteristic Impedance Tolerance | ±3 ohm |

| Conductor DC Resistance | 36.089 ohms/km | 11 ohms/kft |

| Dielectric Strength, Conductor to Shield | 4000 Vdc |

| Jacket Spark Test Voltage | 5000 Vac |

| Nominal Velocity of Propagation (NVP) | 84 % |

| Structural Return Loss | 15 dB @ 1000–3000 MHz | 20 dB @ 5–1000 MHz |

| Structural Return Loss Test Method | 100% Swept Tested |

Product Manufacturing Process

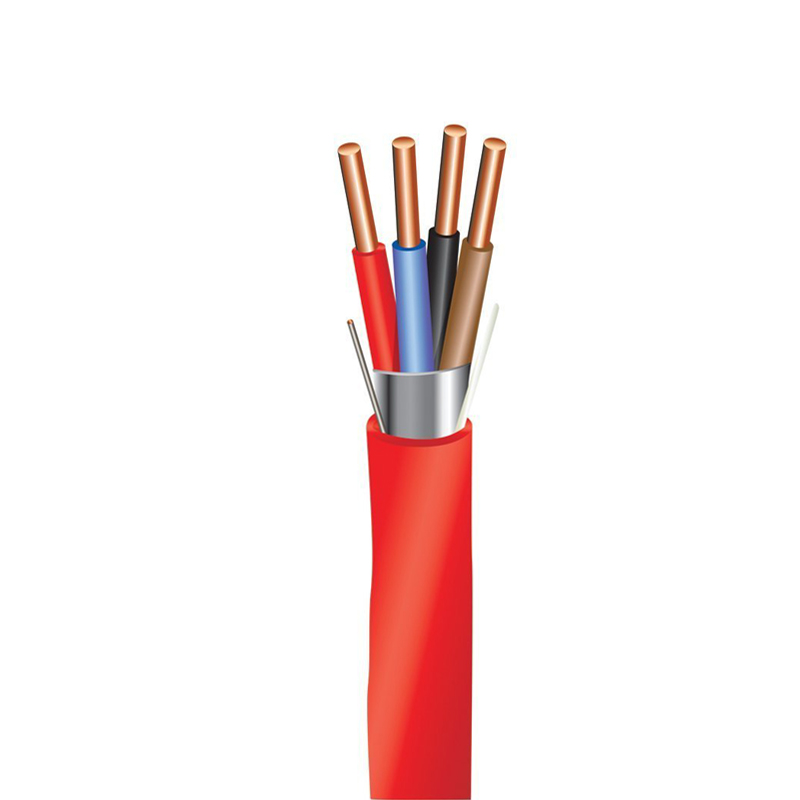

The manufacturing of RG11 cca copper wire involves cladding or electroplating processes where a high-purity copper layer is metallurgically bonded to an aluminum core. This process ensures optimal conductivity while maintaining cost efficiency. The copper layer thickness, typically 10-15% of the overall diameter, plays a vital role in the wire's performance in high-frequency applications. This manufacturing technique combines the benefits of copper with the lightweight properties of aluminum, allowing for practical use across multiple applications. Key challenges include ensuring seamless copper coverage to prevent corrosion, particularly in humid environments. Comprehensive studies suggest that cca copper wire adequately meets the signal transmission needs of modern telecommunications, balancing performance with affordability.

Product Application Scenarios

RG11 cca copper wire is widely employed in telecommunications and networking due to its cost-effectiveness and lightweight properties, making it ideal for large installations where copper wire would be cost-prohibitive. Additionally, its application extends to automotive and aerospace industries where the weight reduction contributes to enhanced fuel efficiency. Though less conductive than pure copper, it provides sufficient performance for data transmission and video distribution in residential and commercial environments. Studies have confirmed its effectiveness in scenarios where conductivity requirements align with its capabilities, making it a preferred choice for budget-conscious projects.

Product After-Sales Service

- 24/7 customer support for technical assistance

- Flexible return policy for defective products

- Comprehensive warranty coverage

Product Transportation

- Delivered via secure and reliable logistics partners

- Flexible shipping options to meet customer requirements

- Packaging designed to prevent damage during transit

Product Advantages

- Cost-effective solution for large-scale installations

- Lightweight, reducing transportation costs

- Sufficient conductivity for many applications

Product FAQ

- What makes cca copper wire cost-effective? The combination of aluminum with a copper coating in cca copper wire significantly reduces material costs while maintaining reasonable conductivity for many uses. This makes it an economical choice, particularly when copper prices are high.

- Is cca copper wire suitable for outdoor use? Yes, while cca copper wire is suitable for many outdoor uses, care should be taken to ensure that the copper cladding is intact to prevent corrosion in harsh environmental conditions.

- How does cca copper wire compare to solid copper wire? While cca copper wire is less conductive, it offers a balance of reduced cost and weight. It is ideal for scenarios where budget constraints are a factor and maximum conductivity is not required.

- What are the main applications for cca copper wire? Primarily used in telecommunications and networking, it is also found in residential wiring and certain automotive applications due to its affordability and adequate performance.

- Does cca copper wire meet international standards? Yes, cca copper wire from Aston Cable meets various international standards including RoHS, CE, and ISO certifications, ensuring compliance with safety and performance norms.

- Can cca copper wire be used in high-frequency applications? Yes, thanks to the skin effect, cca copper wire can handle high-frequency signals effectively, making it suitable for data transmission and other related applications.

- What precautions are necessary when using cca copper wire? Ensure the copper coating is intact to avoid corrosion of the aluminum core, and verify that it meets the required specifications for the intended application.

- Is there any warranty on cca copper wire products? Yes, Aston Cable offers a comprehensive warranty that covers manufacturing defects, ensuring product reliability and customer satisfaction.

- How does cca copper wire affect signal transmission quality? With appropriate use, cca copper wire provides satisfactory signal transmission quality for telecommunications and networking needs, ensuring efficient data transfer.

- What are the environmental considerations for cca copper wire? The use of aluminum reduces resource dependency on copper, and the wire can be recycled at the end of its life, making it a more environmentally friendly option compared to pure copper wire.

Product Hot Topics

- Cost-Effectiveness of CCA Copper Wire in Large Installations The affordability of cca copper wire makes it a preferable choice for large-scale installations. For instance, in telecommunications networks, where vast quantities of cable are needed, the cost savings on materials translate into a substantial financial advantage. Additionally, its lightweight nature eases installation processes and reduces transport costs, contributing further to its cost-effectiveness.

- CCA Copper Wire in High-Frequency Applications The skin effect phenomenon is crucial for cca copper wire's performance in high-frequency applications. It ensures that the signal transmission predominantly occurs on the copper surface, providing adequate conductivity despite the aluminum core. This makes cca copper wire suitable for modern telecommunications and network systems that require efficient signal transfer over long distances.

- Environmental Impact of CCA Copper Wire CCA Copper wire offers a more sustainable option by reducing the dependency on copper, a finite resource. Its recyclability at the end of its lifecycle further enhances its environmental credentials, providing a balanced approach to resource management in industries that consume large amounts of copper.

- Suitability of CCA Copper Wire for Outdoor Installations When considering cca copper wire for outdoor installations, it is vital to ensure that the copper coating remains intact to protect the aluminum core from corrosion. With proper installation and maintenance, cca copper wire performs effectively in outdoor settings, provided that environmental factors are appropriately managed.

- Comparing CCA Copper Wire with Pure Copper Wire While pure copper wire offers superior conductivity, cca copper wire presents a strategic alternative where budget and weight considerations are prioritized. The decision between the two depends heavily on the specific requirements of the project, with cca copper wire offering a practical balance in many scenarios.

- CCA Copper Wire in Automotive Applications The lightweight attributes of cca copper wire translate into better fuel efficiency in automotive applications. In vehicles, every kilogram saved can contribute to reduced fuel consumption, making cca copper wire an attractive choice for automakers focused on improving vehicle efficiency.

- Installation Considerations for CCA Copper Wire Proper handling and installation techniques are paramount with cca copper wire to prevent damage to the copper coating and to maintain the integrity and performance of the cable. Installers must be trained to work with cca copper wire to ensure optimal performance.

- Technological Advancements in CCA Copper Wire Manufacturing Advances in manufacturing processes like better metallurgical bonding techniques improve the durability and performance of cca copper wire, making it a more reliable option for modern applications. These technological improvements continue to broaden the uses and benefits of this versatile cable.

- Challenges of CCA Copper Wire in Corrosive Environments In corrosive environments, the aluminum core of cca copper wire is vulnerable if the copper cladding is compromised. Strategies such as improved cladding techniques and added protective coatings are essential to extending the life span of cca copper wire in these conditions.

- Understanding the Role of CCA Copper Wire in Telecommunications The telecommunications industry benefits significantly from the use of cca copper wire, which supports the vast data transmission demands of contemporary communication networks. Its balance of performance and affordability makes it a mainstay in this rapidly growing sector.

Image Description